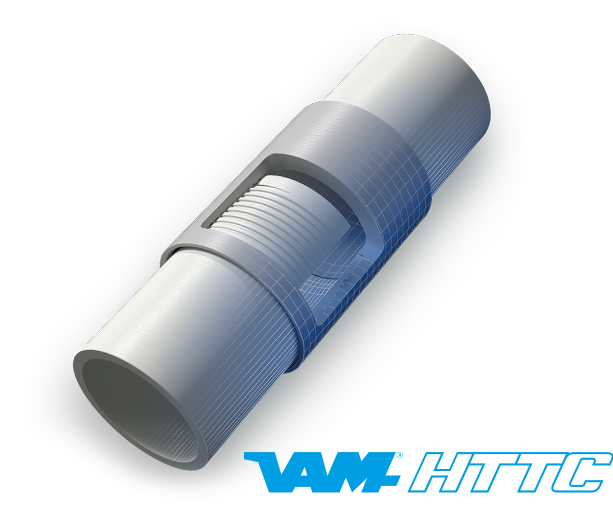

VAM® HTTC

Extreme High Torque T&C with advanced premium performances

VAM® HTTC is the most advanced T&C design in the VAM® product family. Thanks to its optimized self-locking, dovetail thread concept, it combines running reliability, ultra-high torque capacity and ample bending margin, while always ensuring the highest sealability performances. The entire product line is validated against API RP 5C5:2017 / ISO 13679:2019 CAL-IV, including at MTS (Maximum Torque with Sealability).