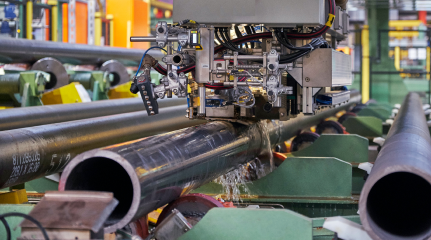

Oil Country Tubular Goods

Whatever the exploration and production challenges for oil and gas, we offer our customers a wide range of solutions.

From conventional to unconventional drilling, onshore, offshore or deep offshore, wherever you operate around the world, Vallourec provides the right combination of seamless pipe, premium VAM® connections and accessories. Our offer extends beyond the supply of products, we can accompany you at every stage of your project with design solutions, inventory management, pipe running operations as well as solutions to optimize your well management.

Every application has specific service requirements to withstand internal and external pressure, high torque, temperature and corrosion. Vallourec offers the full range of material grades and connections to meet your needs. Did you know, we provide OCTG capable of withstanding temperatures up to 350°C for geothermal wells?

VAM® connections are the most widely used connections in the industry, supported by a worldwide network of VAM® Licensees. VAM® 21 offers the highest performance in terms of compression, torque, collapse and high temperature resistance. This is why national and international oil companies around the world have confidence in VAM®.

More information

VAM® 21 has once again gone beyond standard applications to meet the requirements needed to extract hot fluid from geothermal wells. The premium connection was recently installed in two of Geo Dipa Energi’s geothermal wells in the Dieng Plateau in Indonesia withstanding temperatures of up to 330°C. “We are very satisfied with the results obtained with VAM® 21 in our Dieng well, VAM® 21 was ran quickly and efficiently with zero rejects.” - Yudi Hartono, Geo Dipa Energi Drilling Manager

Discover our OCTG Solutions

More information