13Cr and Super 13Cr

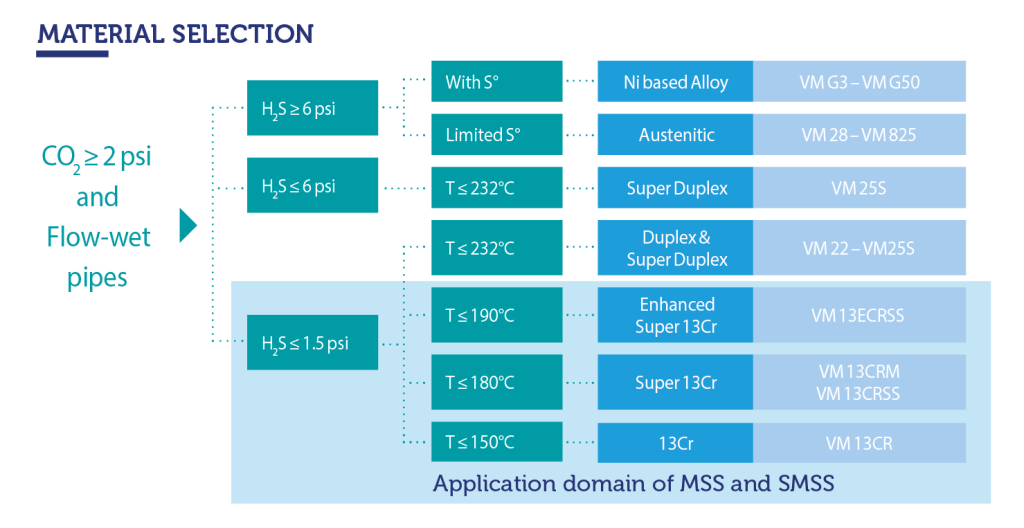

Under CO2 containing environments with limited H2S content, commonly called sweet environment, carbon steel materials are subject to severe general and localized corrosion. This phenomenon can not only lead to failure and replacement of the tubing string, but also to production loss, additional costs related to workover operations, and eventually environmental impacts.

Under such conditions, martensitic (MSS) and super martensitic stainless steels (SMSS) remain the most suitable materials. When chromium contents reach at least 12%, steel pipes form a protective layer, called passive layer. This layer isolates the string from the corrosive fluids and stops the corrosive mechanisms, thus considerably increasing the service life of the string.

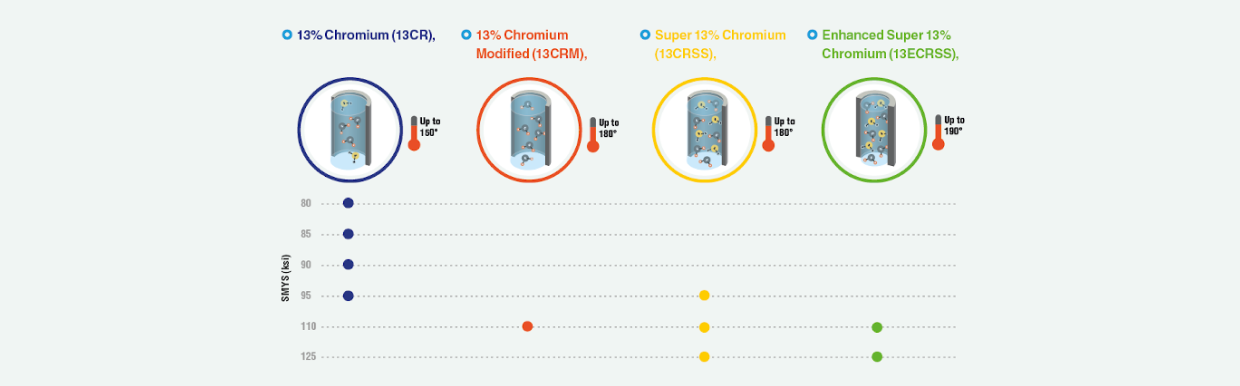

Vallourec has more than 20 years of experience in designing and producing Martentisitic and Super Martensitic alloys to meet the most challenging sweet conditions in oil and gas production operations. This vast grade portfolio is designed to meet the most diverse well conditions, including high CO2 pressure, high chlorides content, and high temperature levels up to 190°C, thus making them suitable for most diverse onshore and offshore applications, including HP/HT wells.

13Cr proprietary grades are the first advanced MSS developed in the 1970’s: they present simpler chemistry leading to limited yield strength range and toughness properties. They are manufactured as per API 5CT and ISO 11960 standards and are fully compliant with L80 13Cr grade. This grade is suitable for use at temperatures up to 150°C and offer mechanical properties up to 95ksi Specified Minimum Yield Strength (SMYS).

Super 13Cr and Enhanced Super 13Cr proprietary grades are enhanced SMSS, presenting enriched chemistry with 5% Nickel and 2% Molybdenum in addition to 13% Chromium (13-5-2). Therefore, it exhibits wide tensile properties from 95ksi up to 125ksi SMYS, excellent toughness properties and enhanced corrosion properties. They are manufactured as per API 5CRA and ISO 13680 standards and are fully compliant with group 1 category (13-5-2). This grade is suitable for use at temperatures up to 190°C.

13Cr Modified (13CrM) proprietary grade presents an intermediate chemistry with 4% Nickel and 1% Molybdenum in addition to 13% Chromium (13-4-1), allowing to reach higher tensile and corrosion properties when compared to standard API L80 13Cr grade at a lower cost than Super 13Cr. 13CrM is offered with 110ksi SMYS and is manufactured based on API 5CRA and ISO 13680 standards as per group 1 category (13-5-2). This grade is suitable for use at temperatures up to 180°C.

| 13Cr | 13Cr Modified | Super 13Cr | |

| Application | Critical Services | Ultra-critical Services | Ultra-critical Services |

| Low Strength | VM 80 13CR | ||

| VM 80 13CRCY | |||

| VM 85 13CR | |||

| VM 85 13CRCY | |||

| VM 90 13CR | |||

| VM 95 13CR | VM 95 13CRSS | ||

| High Strength | VM 110 13CRM | VM 110 13CRSS | |

| VM 110 13ECRSS | |||

| VM 125 13CRSS |

All our Chromium grades are offered combined with the High Collapse grades, visit our High Collapse page for more information.

Our Chromium offer is available in the full range of outside diameter up to 10 ¾” from 80 to 125ksi.

Vallourec Chromium grades have been mainly used in combination with VAM® connections.

13Cr

- Suitable for conventional wells, with sweet CO2 corrosive environment and limited amount of H2S Higher Yield

- Available at 110ksi.

- Suitable for temperatures up to 180°C / 356°F High chloride content and low pH resistance

S13Cr

- Suitable for HP/HT wells with limited H2S Better corrosion resistance with H2S content and at high temperature Higher Yield

- Available from 95ksi to 125 ksi.

- Suitable for temperatures up to 180°C / 356°F

- Suitable for limited H2S content, up to 1.45psi / 0,1 bar

ES13Cr

- Suitable for HP/HT wells with limited H2S Higher alloying elements (Cr, Ni, Mo) enhancing corrosion resistance performance, especially at higher temperatures Higher Yield

- Available at 110ksi and 125ksi.

- Suitable for temperatures up to 190°C / 374°F

- Suitable for limited H2S content, up to 1.45psi / 0,1 bar

| YY | Type of alloy | Controlled Yield |

| 13CR | 13Cr | - |

| 13CRCY | 13Cr | Controlled Yield |

| 13CRM | 13Cr Modified | - |

| 13CRSS | Super 13Cr | - |

| 13ECRSS | Enhanced Super 13Cr | - |

When a next generation of Enhanced grades is developed, an additional “E” is added to indicate its Extended application domain (e.g.: VM 110 13ECRSS).

13Cr grades

For wells subjected to sweet environments, Vallourec offers a wide portfolio of 13Cr Martensitic Stainless Steel grades, available in grades 80 to 95 ksi and strictly compliant with the latest edition of API 5CT and ISO 11960 standards.

The detailed description of each grade is given in a Product Specification.

| GRADES | MIN. YIELD STRENGTH (ksi) | MAX. YIELD STRENGTH (ksi) | MIN. TENSILE STRENGTH (ksi) | MAX HARDNESS MEAN (HRC) | CHARPY - MINIMUM ABSORBED ENERGY ON FULL SIZE SPECIMEN (J) | |

| Transverse | Longitudinal | |||||

| VM 80 13CR | 80 | 95 | 95 | 23 | 31 | 61 |

| VM 85 13CR | 85 | 100 | 100 | 24 | 25 | 51 |

| VM 90 13CR | 90 | 105 | 100 | 26 | 20 | 41 |

| VM 95 13CR | 95 | 110 | 105 | 28 | 14 | 27 |

The growing demand of energy has resulted in a general need to produce fields with a tangible CO2 content, and corrosion mitigation has become a major concern to reduce both production and workover operations costs. Consequently, material resistance against sweet corrosion becomes a must in such environments.

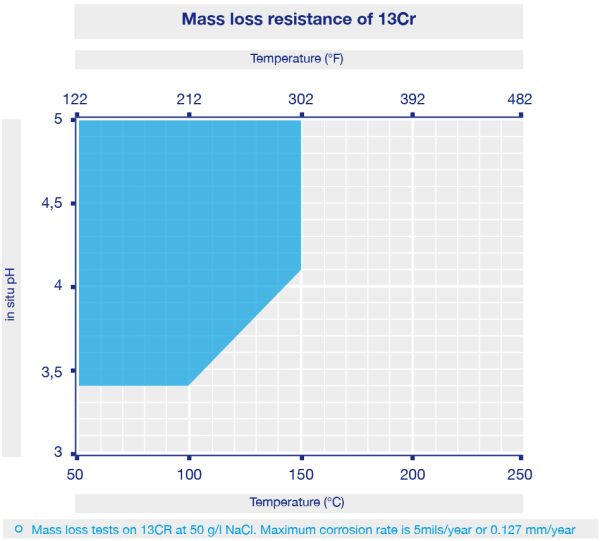

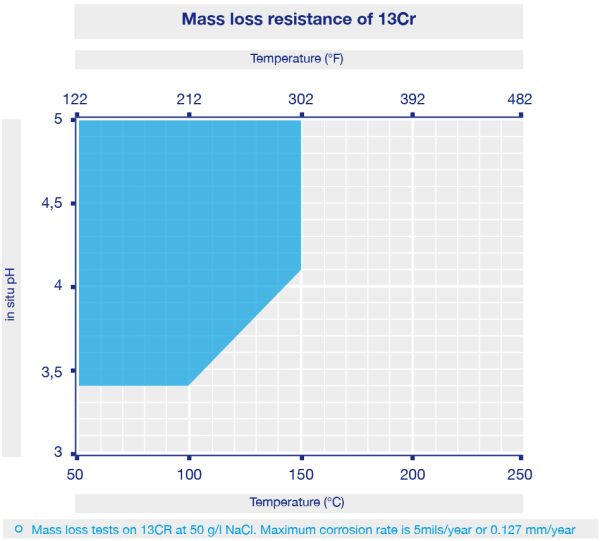

Vallourec 13Cr proprietary grades offer enhanced corrosion resistance thanks to a more controlled chemistry than standard API L80 13Cr. They are suitable for use in conventional wells with sweet corrosive environments. These grades are particularly fitted to be used in low chloride and low-temperature environments up to 150°C, and they additionally offer sour service resistance in limited H2S presence (up to 0.1 bar or 1.5psi ppH2S). With several 100kton of 13Cr sales, these products have been worldwide field proven on conventional onshore and offshore applications, such as South America, Asia, Africa and North Sea.

Additionally, Vallourec has an extensive testing database defining its corrosion performance under several environments to support operators during the material selection process. Here are some examples showing its application domain, however, they should not be interpreted as the maximum application domain of Vallourec 13Cr grades. For additional and more complete information regarding testing results, please contact our technical sales hub.

13Cr and Controlled Yield grades

For environments where an enhanced H2S resistance is necessary in combination with sweet corrosion resistance at low mechanical loads, Vallourec has developed the MSS grade in combination with Controlled Yield properties.

These grades, initially designed for North Sea environments, are available in outside diameter up to 7”, and both 80 and 85ksi are fully compliant with NACE MR0175 specifications, in addition to API 5CT – PSL 2 requirements.

The detailed description of each grade is given in a Product Specification.

| GRADES | MIN. YIELD STRENGTH (ksi) | MAX. YIELD STRENGTH (ksi) | MIN. TENSILE STRENGTH (ksi) | MAX HARDNESS MEAN (HRC) | CHARPY - MINIMUM ABSORBED ENERGY ON FULL SIZE SPECIMEN (J) | |

| Transverse | Longitudinal | |||||

| VM 80 13CRCY | 80 | 90 | 95 | 22 | 31 | 61 |

| VM 85 13CRCY | 85 | 95 | 95 | 23 | 31 | 61 |

The restricted yield strength of these grades provides a lower hardness and higher toughness, thus resulting in an enhanced sulfide stress cracking resistance when compared with regular 13Cr grades.

13Cr Modified grades

For wells requiring corrosion resistance at higher temperature levels as well as higher mechanical properties, Vallourec has developed super martensitic 13Cr Modified grade (13CRM) is available in 110ksi, strictly compliant with group 1, material category 13-5-2 of the latest edition of API 5CRA and ISO 13680 standard.

The detailed description of each grade is given in a Product Specification.

| GRADES | MIN. YIELD STRENGTH (ksi) | MAX. YIELD STRENGTH (ksi) | MIN. TENSILE STRENGTH (ksi) | MAX HARDNESS MEAN (HRC) | CHARPY - MINIMUM ABSORBED ENERGY ON FULL SIZE SPECIMEN AT 32°F (0°C) (J) | |

| Transverse | Longitudinal | |||||

| VM 110 13CRM | 110 | 130 | 115 | 33 | 80 | 100 |

As well depths increase, strings are subjected to more demanding service conditions. Typically, in HP/HT wells the tubing string is subjected to higher formation temperature and higher mechanical loads, therefore requiring more resistant materials.

The optimized chemistry of 13CrM (13%CR, 4% Nickel and 1% Molybdenum, or 13-4-1) represents an intermediate alternative between regular 13Cr grades (13-1-0) and Super 13Cr grades (13-5-2). 13CrM offers better mass loss resistance than standard 13Cr, specially at high temperature. Additionally, it presents higher mechanical resistance, thanks to 110ksi SMYS.

13CrM is recommended to be used in environments presenting exclusively CO2, since it offers a more limited resistance with regards to H2S when compared to 13Cr and Super 13Cr grades.

Vallourec has an extensive testing database on 13CrM grade defining its suitability under different environments at high temperature. Here some examples showing its application domain, however they should not be interpreted as the maximum application domain of Vallourec 13CrM grade. For additional and more complete information regarding testing results, please contact our technical sales hub.

Super and Enhanced Super 13Cr grades

For highly corrosive environments, Vallourec offers wide range of super martensitic stainless-steel grades in 95 and 110ksi, strictly compliant with group 1 material category 13-5-2 of the latest edition of API 5CRA and ISO 13680 standards. Additionally, to reach higher strings mechanical properties without moving to costly CRA materials, Vallourec has developed a 125ksi grade.

The detailed description of each grade is given in a Product Specification.

| GRADES | MIN. YIELD STRENGTH (ksi) | MAX. YIELD STRENGTH (ksi) | MIN. TENSILE STRENGTH (ksi) | MAX HARDNESS MEAN (HRC) | CHARPY - MINIMUM ABSORBED ENERGY ON FULL SIZE SPECIMEN AT 32°F (0°C) (J) | |

| Transverse | Longitudinal | |||||

| VM 95 13CRSS | 95 | 110 | 105 | 30 | 80 | 100 |

| VM 110 13CRSS | 110 | 140 | 115 | 34 | 57 | 85 |

| VM 125 13CRSS | 125 | 140 | 130 | 34 | 57 | 85 |

| VM 110 13ECRSS | 110 | 125 | 115 | 34 | 80 | 100 |

| VM 125 13ECRSS | 125 | 140 | 130 | 35 | 57 | 85 |

Operators are often confronted with challenging well conditions with a combination of high contents of CO2 and elevated temperatures in combination with limited H2S presence. Under such scenarios, in addition to CO2 corrosion risk evaluation, sulfide stress cracking becomes a concern since it can rapidly lead to string cracking failure.

For such environments, Super 13Cr and Enhanced Super 13Cr materials have been field-proven for Deep well, HP/HT, and pre-salt operations worldwide, with several 10kton sold in South America, Asia, Middle East and Africa.

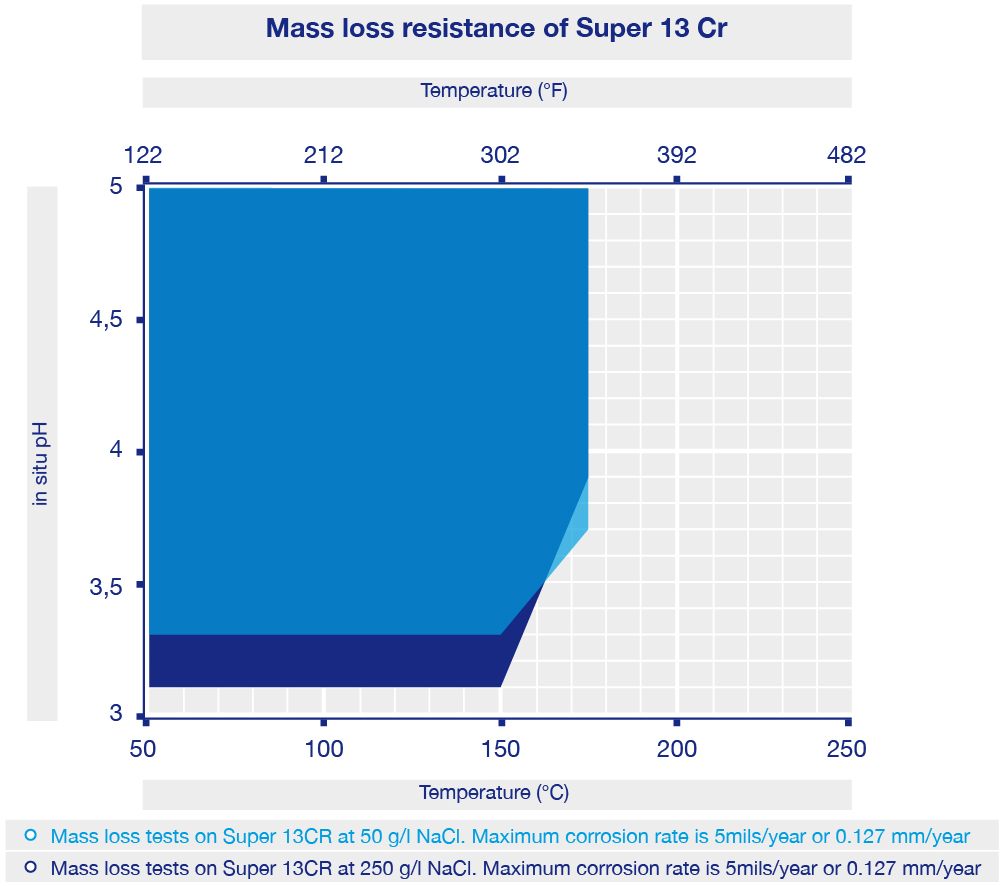

Super 13Cr chemistry, presenting higher content of molybdenum and nickel than 13Cr Modified, allows to reach higher corrosion resistance, particularly at elevated chloride content for both Sulfide Corrosion Cracking as well as Sulfide Stress Cracking mechanisms.

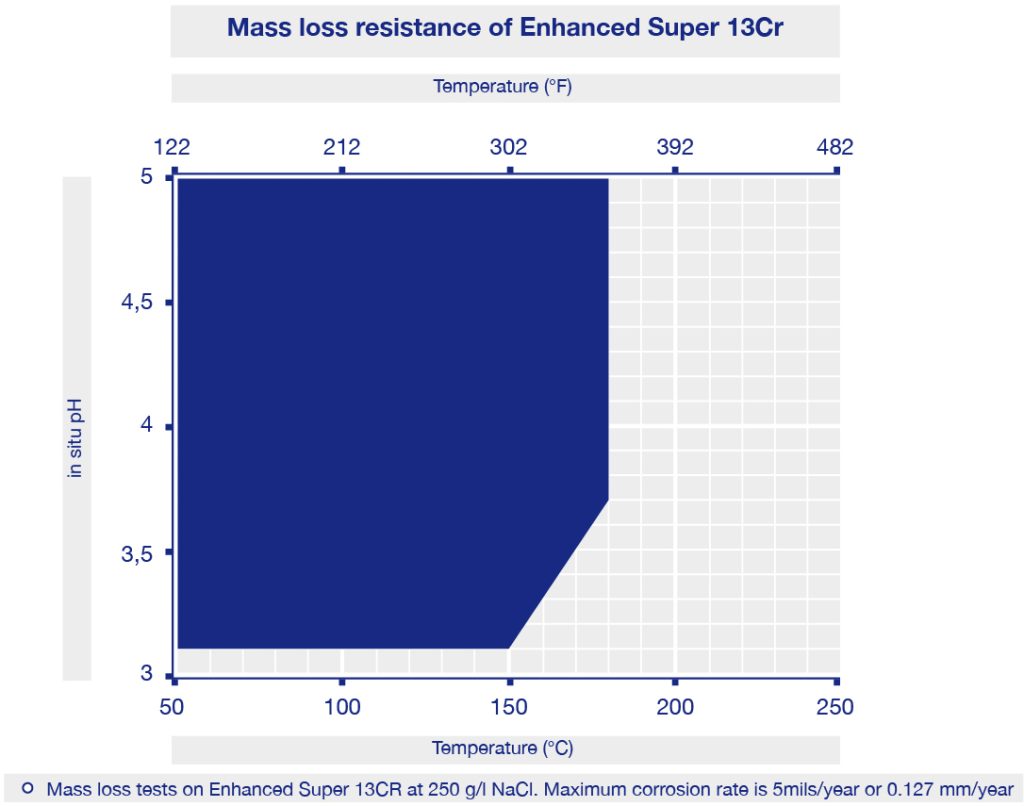

Enhanced Super 13Cr grade (VM 110 13ECRSS) presenting a more controlled and enriched chemistry than regular Super 13Cr grades, is suitable to be used in highly corrosive environments. It is particularly fitted to be used at high chloride content and low pH environments, thus extending the SSC application domain of regular Super 13Cr. Additionally, it offers corrosion resistance at higher temperature levels, up to 190°C.

For decades Vallourec has performed several tests on Super 13Cr materials to evaluate their corrosion resistance under different SCC and SSC conditions, leading to an extensive testing database. Here are some examples showing its SCC application domain, however, they should not be interpreted as the maximum application domain. For additional and more complete information, also including more than a thousand SSC tests covering all combinations of pH and ppH2S for several chloride levels up to 250 000mg Cl-, please contact our technical sales hub.

What is sweet corrosion?

In most well conditions, when the partial pressure of CO2 is above 2psi (0.15bar), carbon steel flow wetted strings are subjected to severe general and localized corrosion, leading to the string early failure and related costs. Corrosion mitigation, as a part of well integrity, must be treated in early stages of the well design in order to reduce operational costs by selecting the appropriate material.

During well design and material selection, corrosion risks assessment is mandatory for all strings that will be in direct contact with the production fluid. Under such conditions, different corrosion mechanisms need to be evaluated considering influencing parameters, such as temperature, pH level, chloride content and corrosive gases content:

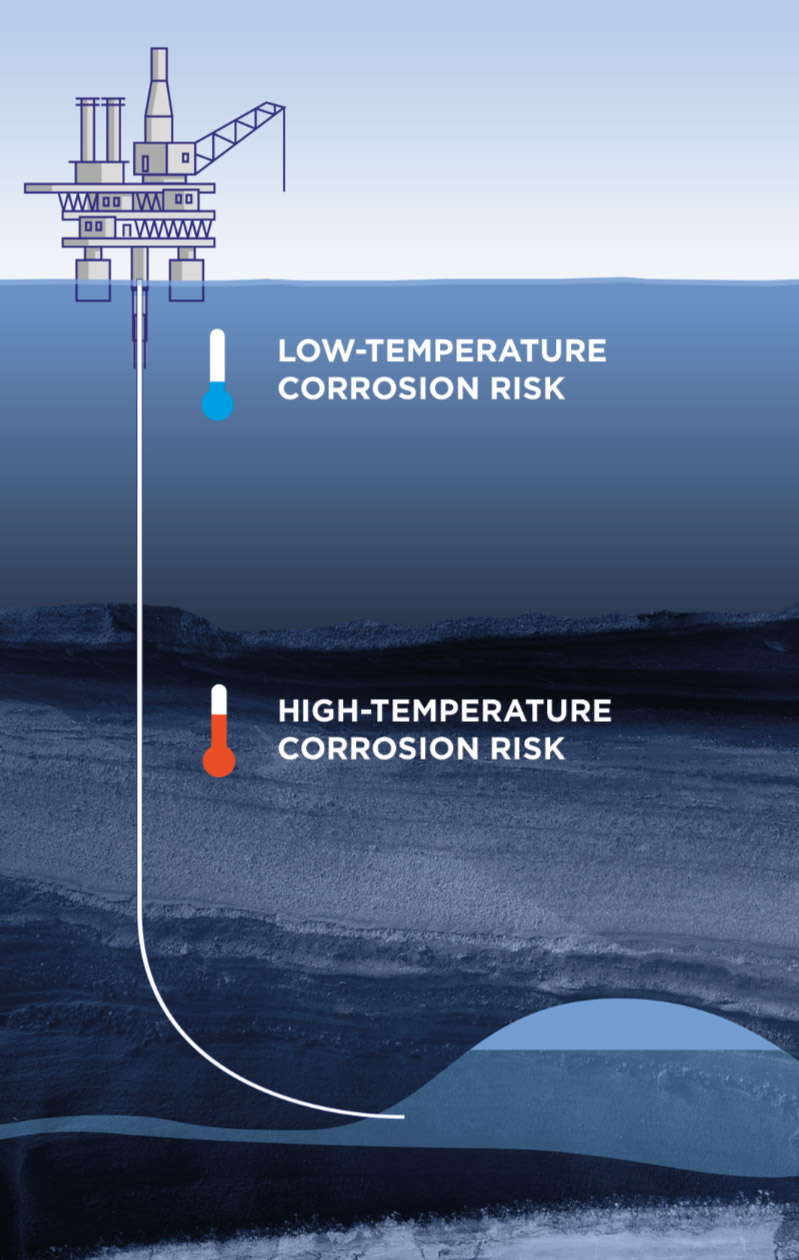

LOW TEMPERATURE CORROSION RISK:

During shut-in phase, the top of the well is subjected to low temperature levels.

Under such conditions and when in the presence of H2S, Sulphide Stress Cracking (SSC) phenomenon is considered to be catastrophic and represents a major concern for operators during well design and material selection, since it can lead to tubular string failure within days or even hours. H2S resistant material therefore becomes a must.

HIGH TEMPERATURE CORROSION RISK:

During production, the tubing string is in contact with formation fluid at high temperatures. Under such conditions,

the two main corrosion mechanisms to be assessed are:

- CO2 corrosion: CO2 drives the acidity and corrosive levels of the environment, since the formation of carbonic acid leads to the occurrence of general mass loss and localized attacks.

- Stress Corrosion Cracking (SCC): cracking of metal that occurs under the unfavorable combination of corrosive environments, high temperature and mechanical loads.

Production phase

During production phase, the whole tubing string is in contact with formation fluid at high temperature.

This fluid contains various soluble inorganic and organic compounds, and is mainly characterized by:

- pH: the in situ-pH is controlled by presence of acid gases and bicarbonate system from formation water. Formation water tends to lower the acidization from CO2, thus increasing in-situ pH.

- Salinity: formation water is normally rich in chloride contents, leading to high corrosiveness and serious risks to damage the tubular strings.

The main corrosion mechanisms that need to be evaluated are the ones enhanced by high temperature levels, meaning CO2 corrosion and SCC at the bottomhole conditions.

CO2 corrosion

CO2 is the principal corroding agent in oil and gas wells, it is the main responsible for driving the acidity and corrosivity levels of the environment due to the formation of carbonic acid.

The main physical phenomenon related to CO2 presence is mass loss. This corrosion mechanism can act both through general mass loss and through acute localized attacks:

- General mass loss can be estimated during material selection evaluation based on environment parameters, and well design can be done according to the expected corrosion rate.

- Localized corrosion, however, can lead to string failure rapidly and with very limited amount of mass loss. Furthermore, the presence of localized corrosion or pitting can lead to other forms of corrosion, such as stress corrosion cracking and crevice, and ultimately to string failure.

CO2 corrosion is mainly enhanced by:- High temperature: It acts as an accelerator on all chemical reactions related to CO2 corrosion.

- Low pH value: Solubility of iron carbonate is increased, thus resulting in lower precipitation rate and increase of corrosion rate.

- High Chloride content: It has a detrimental effect on the passive layer

In addition to the factors mentioned above, other parameters such as organic acids (acetic acid), presence of oxygen, material composition, flow velocity and H2S partial pressure can also influence CO2 corrosion.During material selection, this corrosion risk is generally assessed considering the conditions in the bottom of the well, where the temperature is the highest and the environment is the most critical. Expected corrosion rate in this scenario can be simulated by different models and software available in the industry, or by immersion tests conducted at laboratories under high pressure and temperature.

In general, martensitic stainless-steel materials offer a complete protection against CO2 corrosion thanks to its passive layer, replacing carbon steels and avoiding workover operations during the whole well service life.

Stress Corrosion Cracking (SCC)

According to NACE MR175/ISO 15156 standard, Stress Corrosion Cracking (SCC) is a cracking of metal that will appear under the unfavorable combination of the following activating factors:

• Low pH

• High concentration of CO2 and H2S

• High concentration of chloride content

• External stress

• Microstructure

SCC is mainly enhanced by:

- Higher chloride content: Chloride ions attack the passive film and promote localized corrosion.

- High H2S and CO2 partial pressure: Presence of these corrosive gases decrease in-situ pH value.

- High temperature: It is detrimental for the for the passive layer; and when in presence of localized corrosion, it enhances the anodic dissolution.

During material selection, this corrosion risk is evaluated at the most critical scenario. Since SCC is enhanced with temperature, the former is generally located at the bottom of the well where the temperature is the highest. SCC can be evaluated by means of laboratory tests at high pressure and temperature, replicating the well environment. Vallourec proprietary grades have successfully been tested in autoclaves at high temperatures up to 190°C/374°F.

Shut-in phase

During shut-in phase, the temperature of the well decreases, and the top of the tubing string is in contact with condensation water.

When production flow stops, the level of liquid fluids on the string, such as oil and formation water, lowers. At the top of the well, the string is no longer in contact with formation water, and the remaining fluid in the wall is washed down by droplets of condensation water formed due to temperature gradient. For this reason, sulfide stress cracking assessment is generally made considering shut-in well head condition in contact with condensed water.

Condensation water is characterized by being pure water, and its main parameters are:

- Salinity: very limited (eg.: 1 000ppm Cl-) and no bicarbonates.

- pH: in situ pH mainly driven by the presence of acid gases and pressure profiles. It is generally very low depending on H2S and CO2 partial pressures.

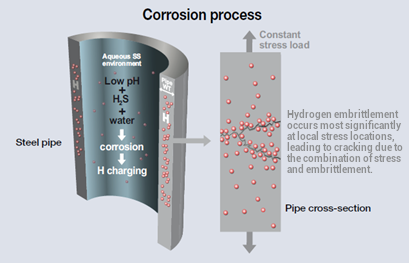

Sulfide Stress Cracking (SSC)

At low temperature, the most critical corrosion risk in sour environments is Sulphide Stress Cracking (SSC). Even at low contents of H2S, SSC phenomenon is considered to be catastrophic and represents a major concern for operators during well design and material selection, since it can lead to tubular string failure within days or even hours.

This corrosive gas, in combination with water and low pH, will release free hydrogen that can be absorbed by the material and fragilize the steel. This embrittlement, in combination with localized residual stress, can lead to crack initiation and ultimately crack propagation and failure of the material.

The SSC will appear under the unfavorable combination of the following activating factors

• Low pH

• High concentration of CO2 and H2S

• High concentration of chloride content

• External stress

• Microstructure

SSC is mainly enhanced by:

- Low temperature: It reduced the diffusion of hydrogen through the material, thus increasing the embrittlement effect.

- Low pH: Increases the acidity level of the environment.

- Higher partial pressure of H2S: It increases the risk of hydrogen atoms penetrating the material, thus increasing its brittleness.

- Applied loads (including residual stress): It increases the susceptibility due to the proximity to the materials yield strength

- Higher chloride content: Chloride ions favor localized corrosion in an environment containing H2S.

During material selection, SSC corrosion risk is generally evaluated at the well head, where the temperature is the lowest and the environment is the most critical. A material resistance to this corrosion mechanism can be assessed through laboratory testing at low temperature and atmospheric pressure.

13Cr and Super 13Cr Standards and Guidelines for OCTG

| Scope | Highlights | ||

| API 5CT | Casing and Tubing | This standard specifies the technical delivery conditions for steel pipes (casing, tubing, and pup joints), coupling stock, coupling material, and accessory material, and establishes requirements for three product specification levels (PSL-1, PSL-2, and PSL-3). | 13Cr proprietary grades are manufactured by Vallourec in accordance with latest edition of API 5CT Grade L80 13Cr PSL-2 specification. |

| ISO 11960 | Petroleum and natural gas industries

- Steel pipes for use as casing or tubing for wells |

This document specifies the technical delivery conditions for steel pipes (casing, tubing and pup joints), coupling stock, coupling material and accessory material. PLS's levels were removed. | 13Cr proprietary grades are manufactured by Vallourec in accordance with L80 13Cr grade of the latest edition of ISO 11960 specification. |

| API 5CRA / ISO13680 | Petroleum and natural gas industries

- Corrosion-resistant alloy seamless tubes for use as casing, tubing and coupling stock

- Technical delivery conditions |

This International Standard specifies the technical delivery conditions for corrosion-resistant alloy seamless tubulars for casing, tubing and coupling stock for two product specification levels (PSL-1 and PSL-2). | Super 13Cr proprietary grades are manufactured by Vallourec with group 1, material category 13-5-2 of the latest edition of API 5CRA and ISO 13680 - PSL-1 specifications. |

| ANSI/NACE TM0177 | Laboratory Testing of Metals for Resistance to Sulfide Stress Cracking and Stress Corrosion Cracking H2S Environments | This standard covers the testing of metals subjected to tensile stresses for resistance to cracking failure in low-pH aqueous environments containing H2S. | It defines 4 testing methods (A, B, C and D) and 4 testing solutions (A, B, C and D) to assess materials resistance. NACE methods A and C are the most used for martensitic and super martensitic stainless steels. |

| ANSI/NACE MR0175/ISO 15156 | Petroleum, petrochemical, and natural gas industries - Materials for use in H2S-containing environments in oil and gas production |

This document gives requirements and recommendations for the manufacture of metallic materials for service in equipment used in oil and gas production and in natural-gas sweetening plants in H2S-containing environments, whose failure can pose a risk to the functionality of the equipment, or to the health and safety of the public and personnel or to the environment. | Its part 3 gives requirements and recommendations for the selection and qualification of CRA's (corrosion-resitant alloys). Annex B defines three different testing protocols or environments to simulate the actual service well environments, considering testing protocols at both high pressure and temperature, as well as at room pressure and temperature. |

Sweet Corrosion testing

In the Oil and Gas industry, corrosion application domain and properties of martensitic stainless-steels are defined based either on operator’s field experience or on laboratory qualification testing during well design and material selection phase. For the later, several different testing protocols can be used to simulate a corrosive environment, such as standard NACE tests, or more recently developed state-of-the-art fast-screening tests.

Standard NACE tests

Industry standard NACE TM0177-2016 is the reference standard which defines how to perform test to evaluate resistance of metals in H2S and CO2 containing environments. It describes 4 different testing protocols, among them the most used to assess martensitic stainless-steel corrosion performance are NACE A and C.

Additionally, ASTM G39 – ISO 7539 covers procedures for designing, preparing, and using bent-beam stress-corrosion specimens.

These tests can be launched at both room temperature to evaluate material suitability with regards to sulfide stress sracking and at high temperature to evaluate material suitability with regards to stress corrosion cracking

| NACE A | NACE C | Four Point Bending | |

| Standard | NACE TM1077 | NACE TM1077 | ASTM G39 - ISO 7539 |

| Stress apllication | Tensile - % AYS or SMYS | C-ring - %AYS or SMYS | FPB - %AYS or SMYS |

| Duration | 720hs | ||

| Result | Pass / Not pass | ||

| SCC assessment (Temperature / Pressure) | High | ||

| SSC assessment (Temperature / Pressure) | Low (generally 24°C) / 1 bar | ||

| Testing sample |  |

|

|

allourec has dedicated testing facilities, equipped with efficient CO2 and H2S corrosion investigation tools such as electrochemical and autoclave equipments to perform these tests and support material selection analysis, and a database of more than 800 tests conducted on MSS and SMSS following these standard recommendations.

Advanced testing

Vallourec extensive testing database, and vast expertise on testing protocols and Material Selection has allowed us to offer fit-for-purpose qualification, in order to better represent your well conditions and confirm material suitability. Based on a complete review of different scenarios expected for the intended service conditions, Vallourec can support on testing matrix definition for a Fit-for-purpose qualification as per customer request.

Some of the services Vallourec can provide include:

- well environment simulation using OLI software and in-situ pH calculation for both formation and condensation water scenarios.

- fast-screening testing such as Cyclic Potentiodynamic Polarization curves (CPP) and ripple strain rate tests allows a fast and reliable screening of SSC performance of a martensitic and Supermartensitic stainless steels in a given environment. Such methods could be of great importance for the first steps of material selection

- for oil and gas applications being less costly in terms of time and money than the NACE TM-0177-2016 standard Method A. For additional information, please contact us.

- HP/HT tests in autoclave: Service simulation at actual well pressure and temperature allow a most representative test environment.

NACE - 2019

C. Millet, F. Decultieux, C. Gomes, S. Song

SPE - 2018

J. Oliveira, S. Tchoundjeu, G. Néel, Vallourec Oil & Gas France, V. Richoux, Vallourec Research ; Center France, D. Sareen, P. Bezboruah, Badr Petroleum Company

NACE - 2018

C. Millet,V. Richoux, F. Decultieux, G. Néel, S. Song, H. Evin - NACE Genoa

-"Material qualification under specific well environment allow to improve the material selection replacing CRA duplex material by cost effective solution S13Cr material.” Vallourec and Badr Petroleum Company; paper SPE-190914-MS, “Cost Effective Material Selection for Sour and Sweet HPHT Field”