CLEANWELL® – VAM® Dope-free Coating

CLEANWELL® is a non-polluting, multi-function coating replacing both storage and running compounds applied on the surface of VAM® connections. It is designed to provide exceptional anti-corrosion and lubrication properties.

Dope-free coating solution

Providing increased performance

CLEANWELL® integrates a multi-layer dry coating that combines anti-corrosion and lubricant properties. It protects tubing and casing connections against potential problems such as corrosion, and, for more critical materials such as chromium or high alloy grades, it prevents galling wear caused by friction during make-up.

CLEANWELL® connections greatly reduce back-out and reject rates during operation. The result: less production downtime and higher operational efficiency that keep cost overruns to a minimum. In fact, CLEANWELL® generates significant cost savings over the lifecycle of the pipes.

State-of-the-art technology

Vallourec’s CLEANWELL® solution is based on a multi-layer system featuring a dry engineered lubricant film applied in the mill on premium OCTG connections as an alternative to storage and running dopes, demanding less manual operation on the jobsite.

- A metal-based plating layer protects against corrosion and galling

- A thermoset topcoat offers dry lubrication to ensure extreme repeatability and stability during make-up, plus extra anti-corrosion benefits

CLEANWELL® has been qualified according to the industry’s most demanding protocols, including API RP5 C5:2017 CAL-IV and ISO13679:2019 CAL-IV.

Benefits

Performance

Applications & Product Range

Product Range

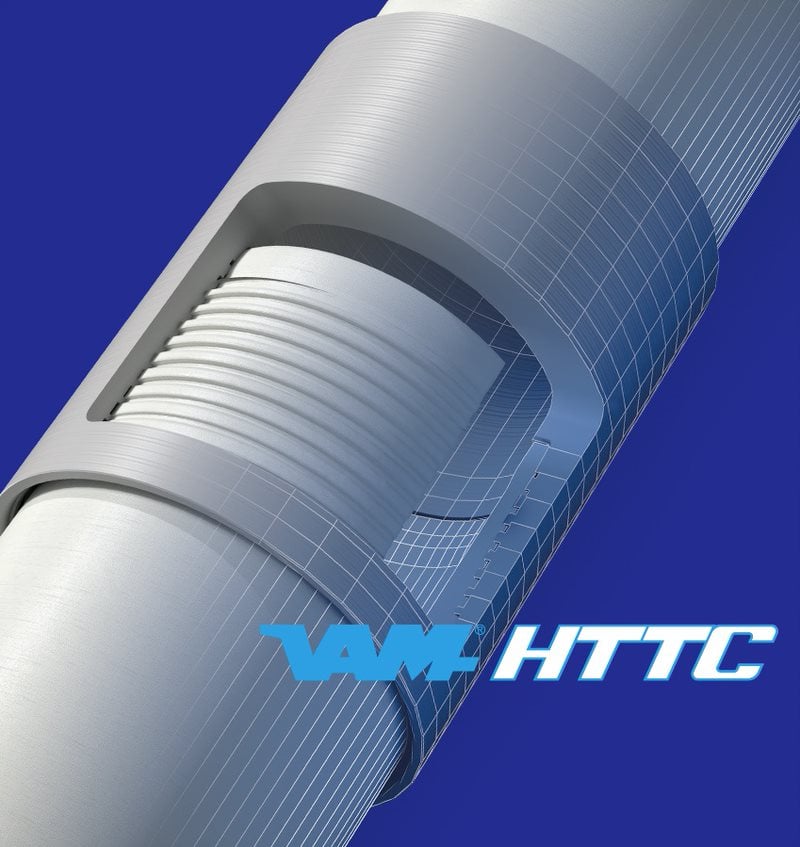

- Available for VAM® 21, VAM® SLIJ-3, VAM® HTTC in sizes from 3-1/2” to 16”. Available on other VAM® connections upon request.

- Carbon Steels including Sour Service grades, 13Cr, S13Cr and Corrosion Resistant Alloys

- Yield Strengths from 80 to 125 ksi

Applications

- Offshore wells

- HP/HT wells

- Deviated wells

- New Energies: CCS, Hydrogen & Geothermal

- Deep and ultradeep wells

Documents & Resources

Wintershall has introduced Vallourec’s dope-free solution CLEANWELL® into their recent operations. First results show clear advantages and cost savings throughout the OCTG product’s life cycle all while reducing safety risks and environmental impact. During the operations involving CLEANWELL® tubulars, Wintershall Dea noted a gain in efficiency throughout the pipe life chain all while complying with HSE regulations.