Shale

Shale wells are pushing equipment harder than ever – extreme rotational torque, longer laterals, and higher rotational and pressure‑cycle fatigue loads. Vallourec delivers integrated, data‑driven OCTG solutions built specifically for these demands. Every recommendation is tailored to your well design to help reduce risk, accelerate drilling, and optimize cost performance.

Your Well. Your Goals. Our Solutions.

Developing shale and tight oil wells requires more than simple products—it requires trusted partners who understand the challenges you face.

Proven Value in Shale Environments

Shale wells are pushing equipment harder than ever – extreme rotational torque, longer laterals, and higher rotational and pressure‑cycle fatigue loads. Vallourec delivers integrated, data‑driven OCTG solutions built specifically for these demands. Every recommendation is tailored to your well design to help reduce risk, accelerate drilling, and optimize cost performance. And with every product in our shale portfolio designed, manufactured, and tested in the U.S., you gain the performance you need with the local support you trust.

Engineered for Today’s Shale Challenges

- Handles extreme rotational torque

- Proven in extended‑reach laterals

- Enhanced resistance to rotational and cyclic fatigue

Value You Can Count On

- Optimized reliability and cost efficiency

- Lower production cost per foot and minimized running time

- Well integrity assurance through fit‑for‑purpose validation

- Engineered and built in the U.S., trusted worldwide

Our local shale experts are ready to support your next well.

Performance Under Pressure

Gas Connections: High Torque, Reliable Sealing

Vallourec’s gas connections are built for the toughest conditions, providing exceptional torque, certified gas-tightness, and easy running.

Proven Performance for Shale Gas

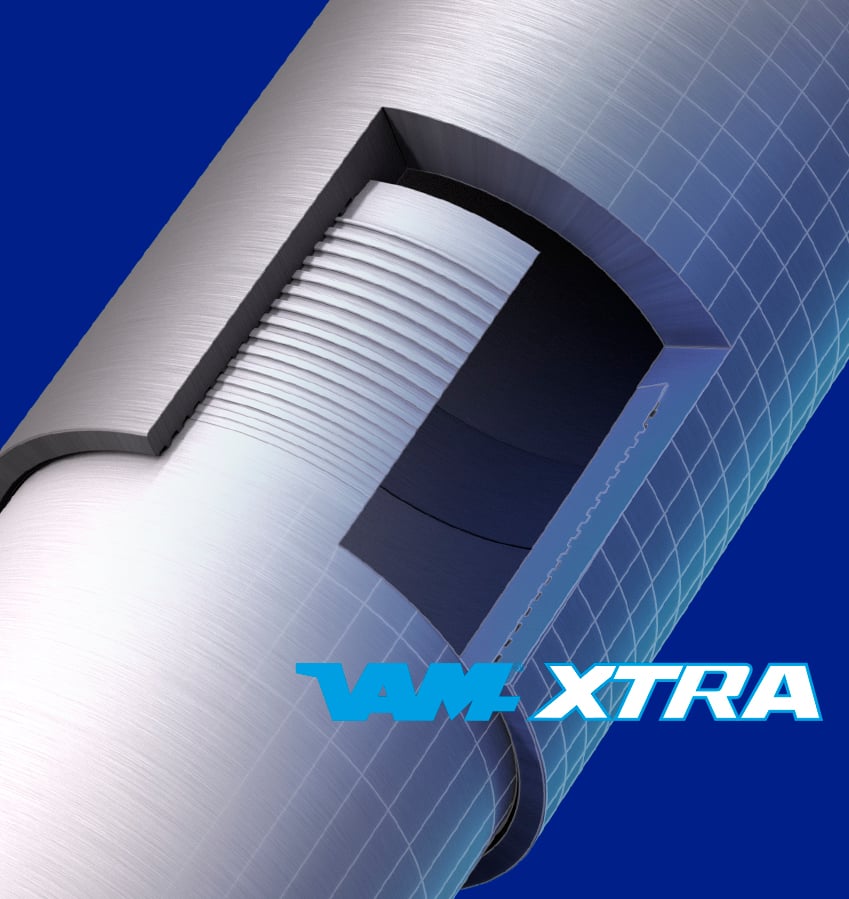

VAM® XTRA is a premium threaded and coupled connection engineered for extreme high-torque shale gas applications. Featuring VAM®’s industry-proven hooked thread, it has been validated to meet the unique challenges of shale, delivering consistent and reliable performance where it matters most.

- OD: 4.5” – 6”

- Grades: all carbon and mild sour grades

- YS: 80 – 125 ksi

Reliability for Extreme Long Laterals

VAM® EDGE SF+ is a gas-tight premium connection engineered with a tapered two-step thread design for deep stabbing and minimal cross-threading risk. With exceptional tension and torque capacity, it ensures reliable performance for full-string production casing in demanding Shale wells and extended horizontals.

- OD: 4.5” – 5.5”

- Grades: all carbon and mild sour grades

- YS: 9 5 – 125 ksi

Liquid Connections: Smooth Running, Reliable Performance

Vallourec’s liquid connections are engineered for smooth make-up, high tension, and extreme torque capacity, supporting wells with extended laterals and tight clearances.

High Rotational Torque

VAM® SPRINT-TC is the capstone of the SPRINT series, offering a semi-premium threaded & coupled connection designed for extended reach laterals and high-rotation operations in shale wells. It delivers 100% pipe body ratings, extreme operational torque, and low hoop stress, while requiring less than 5 turns to make-up. A slim coupling option is available to meet specific operational needs.

- OD: 4.5” – 6”

- Grades: all carbon and mild sour grades

- YS: 80 – 125 ksi

Extreme Clearance, High Torque and Tension

VAM® SPRINT-SF is a semi-premium, high-torque connection built for extreme shale applications. Its semi-flush design, combined with a high-tension rating and ultra-high torque capacity, makes it ideal for running a full string as production casing in wells with extended horizontal sections and tight clearances.

- OD: 4.5” – 6”

- Grades: all carbon and mild sour grades

- YS: 95 – 125 ksi

Expertise Re-Engineered for Unconventional Wells

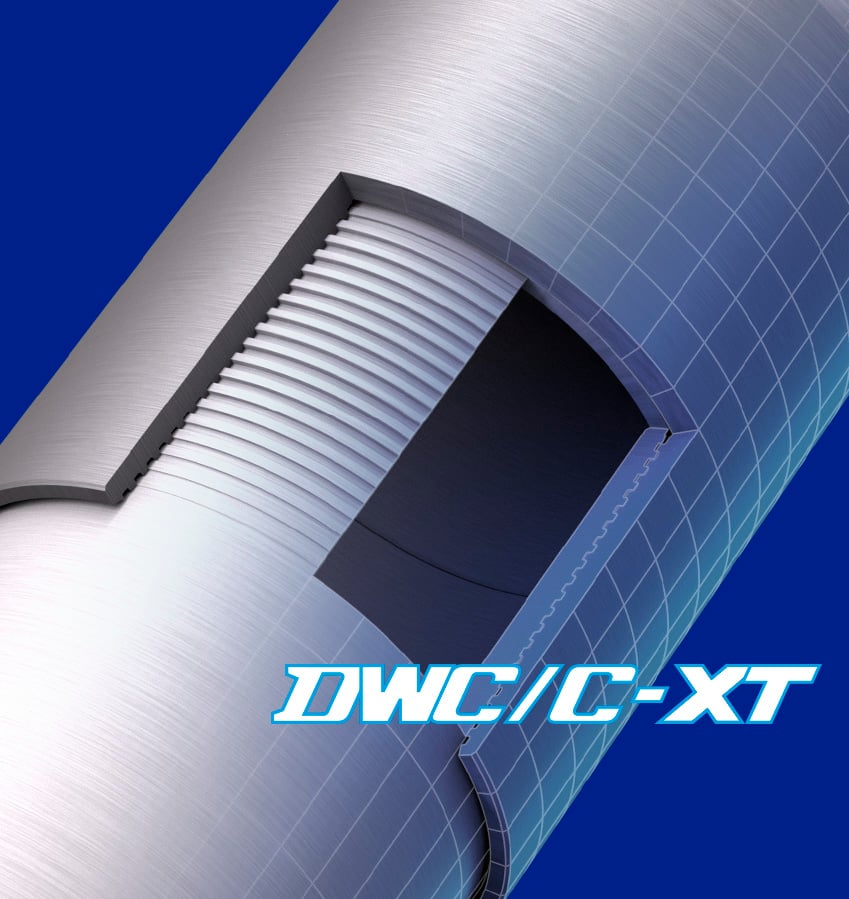

DWC/C-XT is a semi-premium threaded and coupled connection that combines extreme torque with buttress-compatible performance. Designed for extended laterals and unconventional wells, it provides smooth handling and cost-efficient operation, building on over 30 years of trusted DWC/C expertise.

- OD: 4.5” – 6”

- Grades: all carbon and mild sour grades

- YS: 55 – 125 ksi

Engineering Backed by Testing

In shale operations, every connection plays a critical role. Yet no industry standard specifically targets the demanding loads encountered in these wells. That’s why Vallourec developed its own testing protocol to give you confidence before the pipe ever reaches your rig. Our proprietary VAM® Shale Protocol goes beyond ISO 13679 and API RP 5SF requirements, replicating the real‑world stresses of torque, tension, bending, fatigue, and pressure. By testing under representative downhole conditions, we ensure our connections are qualified for the challenges they will face in the field—supporting well integrity and long‑term reliability.

Tested for Purpose with Our VAM® Shale Protocol

Installation

FATIGUE TESTING SIMULATING ROTATION AT INSTALLATION

- Fatigue testing under extreme dogleg severities (up to 30°/100ft)

- Drift maintained after max operational torque and fatigue

Fracturing

PRESSURE AND TENSION CYCLING TO SIMULATE FRAC OPERATIONS

- Post Fatigue samples subjected to more than 100 maximum internal pressure & tension cycles

Production Integrity

SEALABILITY TESTING FOLLOWING API 5SF AND API 5C5: 2017

- Post fatigue and frac samples subjected to production cycles with elevated temperatures (up to 350°F), bending (30°/100ft), and maximum operational torque

- Additional gas sealability testing on premium and semi-premium connections

End-to-End Technical Support

We don’t just deliver pipe – we deliver a partnership. Vallourec is at your side to support your goals, adapt to fast‑moving well programs, and solve problems proactively:

- Engineering services for well design, material selection, corrosion testing, and torque & drag analysis

- Customizable solutions for grades, connections, and accessories

- Onsite or remote operational support and troubleshooting

- Agile logistics and scalable support to flex with activity and cost needs

- Complimentary training on steelmaking, tubulars, and connections

Smart Run Complete: Everything. Connected.

Delivering speed, efficiency, and confidence to onshore operations

Smart Run Complete streamlines casing operations with a lean, integrated service model that saves time and minimizes risk. With VAM® Certified Representatives on site, you gain expert assurance to execute drilling plans efficiently and securely while

reducing personnel at the wellsite without sacrificing performance. By placing the mill directly alongside the operator, Smart Run Complete enables faster decisions, stronger integrity, and a smarter way to run casing.

Smart Run Complete Includes:

- Rig-Ready Pipe

- Digital Tally & Pipe Traceability

- VAM® Field Service

- Thread Reps

- Torque Turn

- Casing Running Tools

- Torque & Drag Modeling & Monitoring