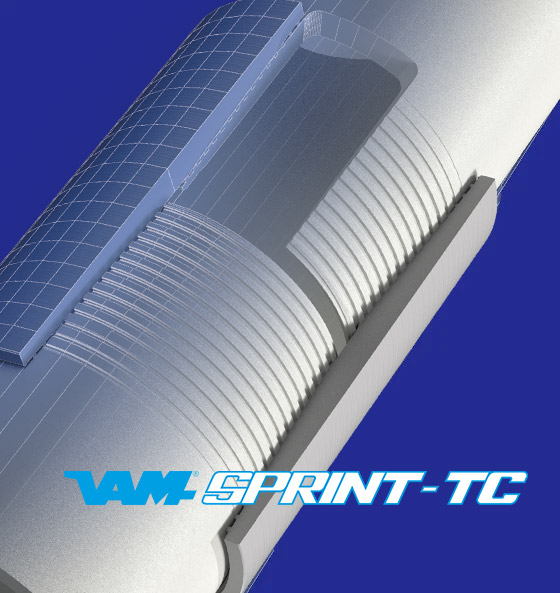

VAM® SPRINT-SF

Ultra high torque capacity for Shale applications.

VAM® SPRINT-SF, the first in a series of semi-premium high torque products for shale, is a semi-flush connection innovatively designed for extreme shale applications. Its high tension rating and ultra high torque capacity make it ideal to run a full string length as production casing in shale wells with extended horizontal sections and tight clearance requirements.