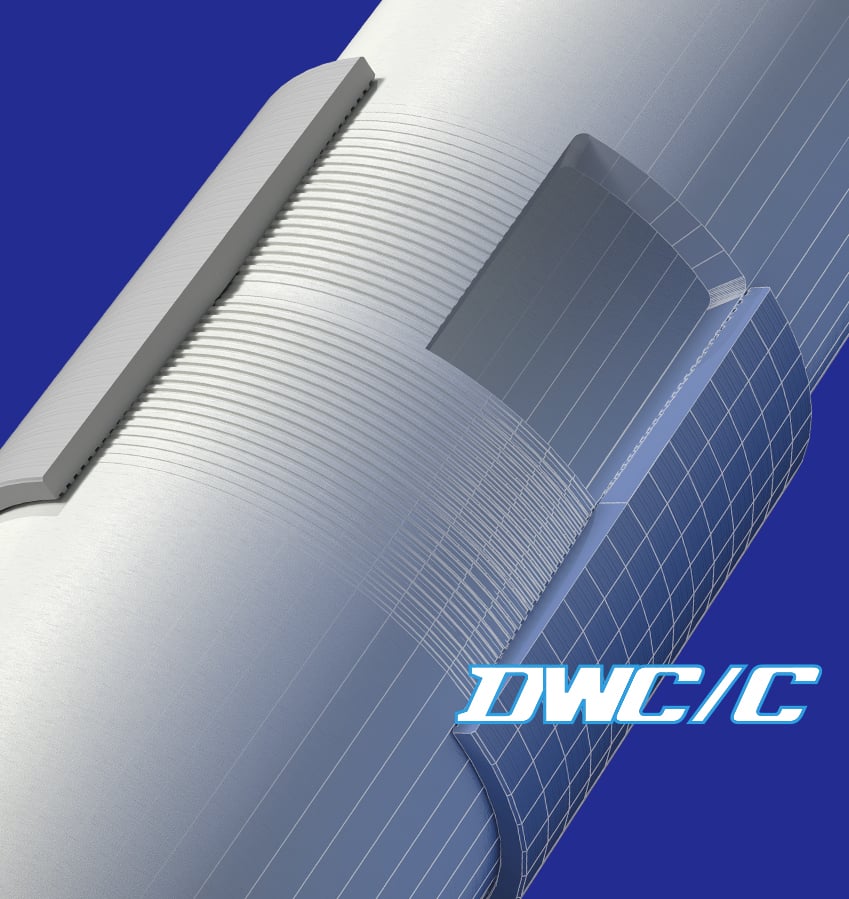

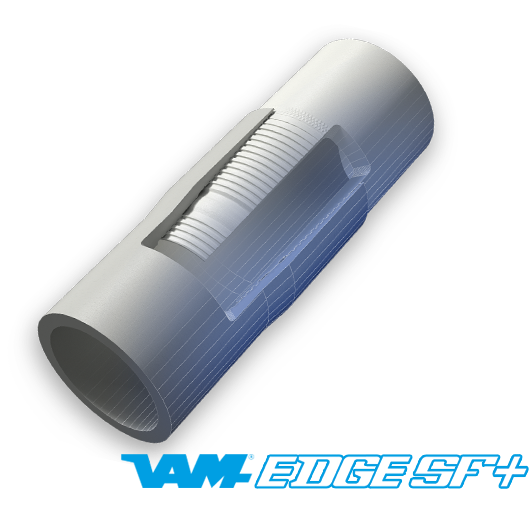

VAM® EDGE SF+

Premium semi-flush connection with ultra high torque capacity for Shale applications

A gas-tight semi-flush premium connection, VAM® EDGE SF+’s high-tension efficiency plus extreme high-torque capacity make it ideal to run a full string length as production casing in shale wells. Designed specifically for extreme shale applications, VAM® EDGE SF+ offers a single Fit for-Shale solution for both vertical and extended laterals up to 15,000ft.