Glass Reinforced Epoxy (GRE) liners

Providing cost-effective corrosion protection for your injection wells.

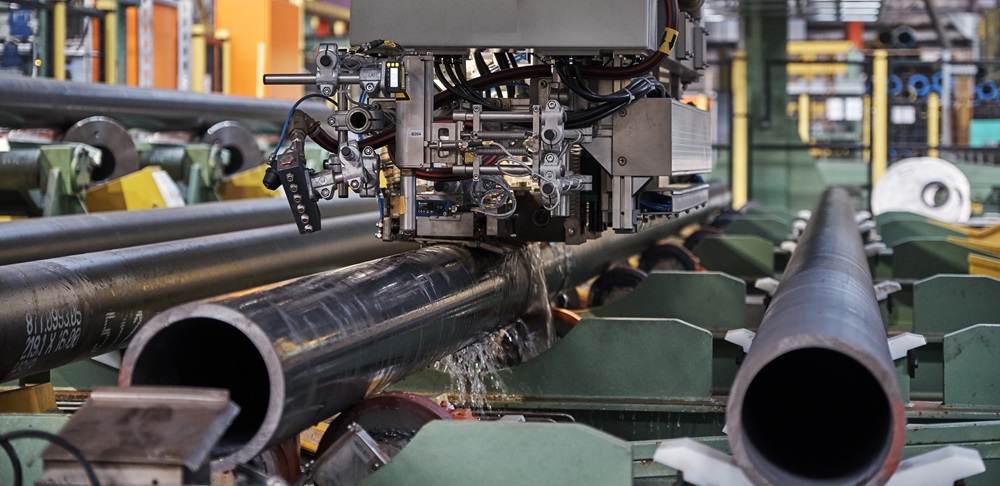

Injection wells are known to face complex environments, such as untreated fluids, high salinity, corrosive gases (CO2, H2S, O2) and microbiology activity. Carbon steel tubings with Glass Reinforced Epoxy liners are field proven in such corrosive environments replacing costly CRA grades.

Vallourec has developed this solution with the best partners to maintain both the pipe and the connection integrity.

Benefits

Benefits

Cost effective

GRE solutions are a good alternative to costly CRA grades.

Complete portfolio

Designing your well? Our GRE products are validated for most tubing and casing sizes required by the market, combined with our VAM® connections.

Field proven

Successfully run on injection and production wells in Middle East, North Sea, Offshore Africa and South America, among other areas.

Performances

Performances & Applications

- GRE liners provide an effective long-term corrosion protection for several applications, such as water injection, wet CO2 injection, and production wells.

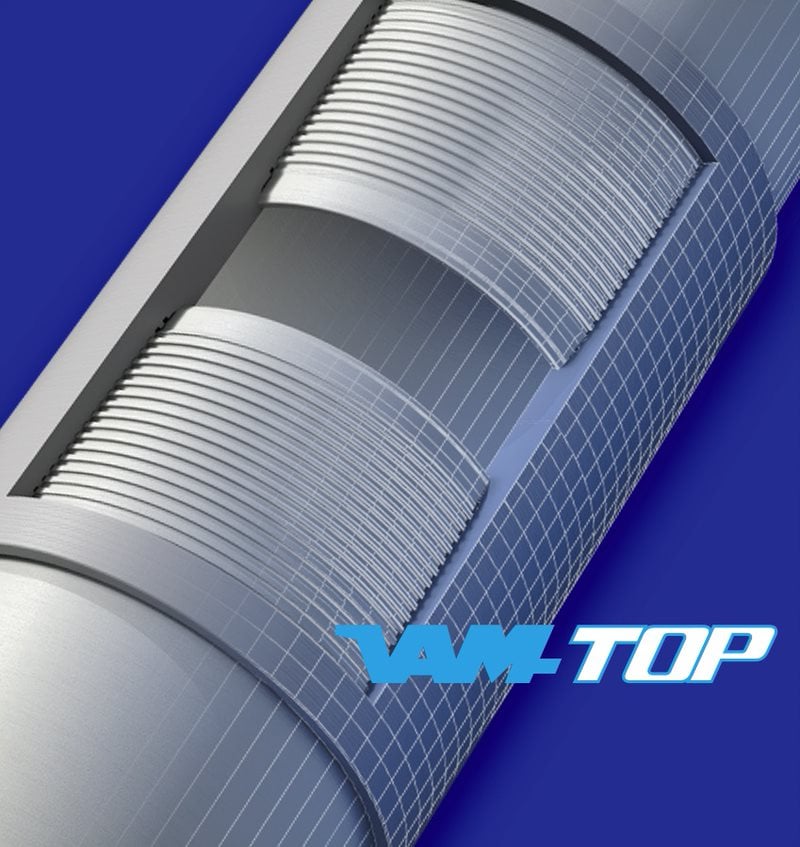

- GRE liners solutions are fully compatible with our VAM® TOP and VAM® 21 premium connections, with no design modification required and same torque table applicable.

- Both VAM® TOP and VAM® 21 solutions fitted with GRE liner have been tested as per ISO 13679: 2002 CAL IV up to 120°C.

- Vallourec offers design solutions for CRA accessories to ensure continuity of the corrosion protection with GRE pipes.

- For other GRE liner applications, please contact us.

Application domain

- Temperature: up to 250°F/121°C.

- Pressure: up to the pipe performance in combined loading (VME envelope of pipe).

- Maximum decompression rate: 100 psi/min.

Resources

Documents & Resources

Brochure

13Cr & Super 13Cr Grades brochure

Reliable, Cost-effective Solutions for sweet CO2 environments

Vallourec e-learning

Interested in learning more about well design and material selection? Fill in this form to access the e-learning session. By filling in this form, you are sharing your information with Vallourec and acknowledge that you have read and agreed to the Data Privacy Policy (https://solutions.vallourec.com/en/Cookies).

Interested in learning more about well design and material selection? Fill in this form to access the e-learning session. By filling in this form, you are sharing your information with Vallourec and acknowledge that you have read and agreed to the Data Privacy Policy (https://solutions.vallourec.com/en/Cookies).

OCTG Expertise Center

Every application has specific service requirements to withstand internal and external pressure, high torque, temperature and corrosion. Vallourec offers the full range of material grades and connections to meet your needs. Our Expertise Center is the priviledged place to exchange with our experts.

Discover our Solutions

More information