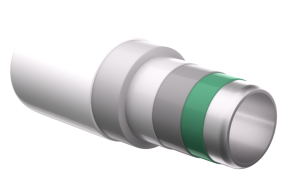

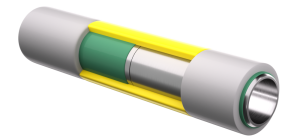

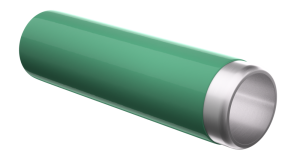

FBE is a fundamental anti-corrosion coating used to protect steel pipes from aggressive environments. The bonded epoxy resin is applied as a dry powder onto preheated steel surfaces, forming a strong protective layer with a typical thickness of 400–600 microns.