An operator was planning an offshore project with a riser made of 41 mm-thick pipes in X65 steel.

This would require the use of buoyancy modules in what is known as a steel lazy wave riser ( SLWR) configuration.

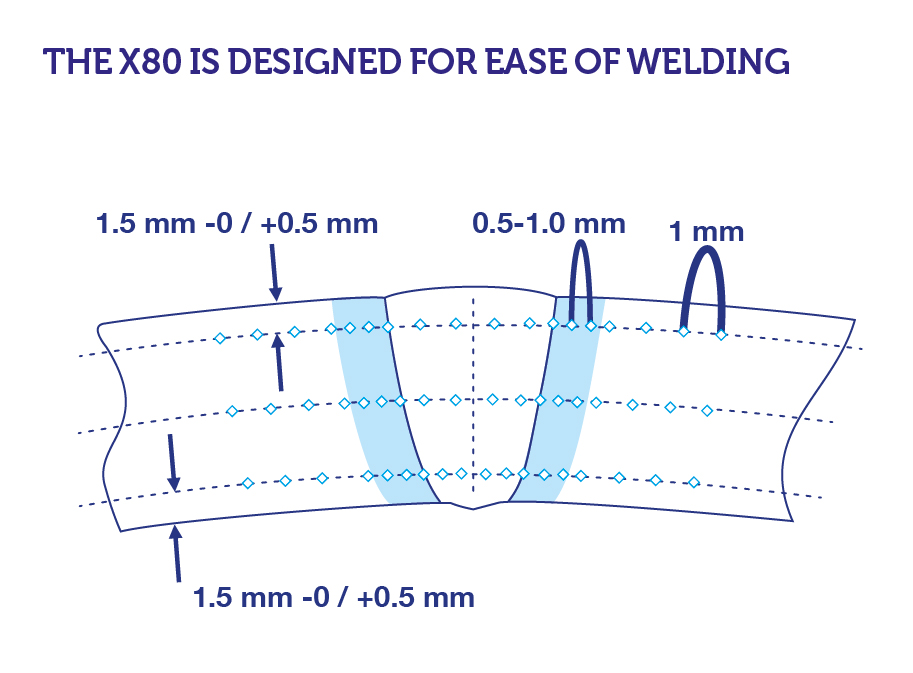

By replacing the X65 grade with X80, the operator was able to reduce the wall thickness of the riser pipe to 32 mm. This, in turn, eliminated the need for buoyancy modules.

Thanks to this steel catenary riser configuration (SCR), the X80 helps to lower project installation costs. The reduced wall thickness helped the operator eliminate more than 2,000 tons of steel production, which translated to cost savings of around $2 800/ton.

In addition, installation time was shortened by a full 12 days, saving up to 3,500 metric tons of CO2 emissions, as estimated along the entire value chain (i.e. from the raw material supply to the transport to final destination), according to the EPD International PCR 2012:01 standard (2012).