Well Design

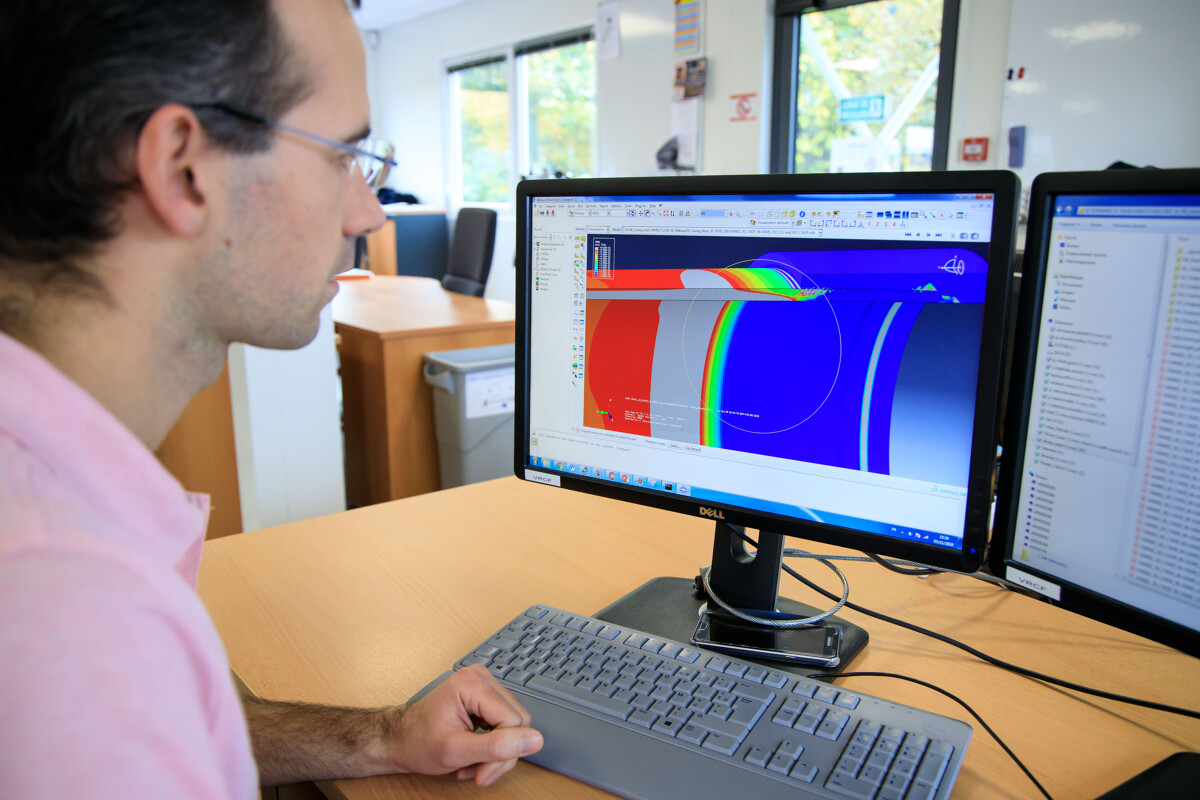

Using industry-reference software simulations, our teams of well design professionals provide expertise and share best practices from across the industry. At the early stage of well design, we can analyze and evaluate load cases, safety factors or design scenarios. Together with the material selection team, our experts can help you design a lighter and safer well by selecting the most appropriate products and data from Vallourec’s portfolio.

Designing a well is a complex process that requires careful planning to ensure safety, cost-efficiency, and productivity. At Vallourec, our Well Design Service, in collaboration with the client’s drilling department, provides a comprehensive review of the base design and works on optimizing product selection. This involves:

- Selecting the appropriate pipe grade and weight

- Choosing the suitable connections

Vallourec offers a wide range of grades and connections tailored for various applications and environments. We understand that operators often prefer familiar, time-tested products, but our goal is to help you identify the best options for your specific needs. Well design optimization is a multidisciplinary effort. To assist you in designing lighter and safer wells, Vallourec has developed several areas of expertise:

Casing Design Assessment

Using the latest industry software, we can evaluate your casing design and suggest optimizations regarding sizes, grades, and connections from our proprietary products.

Material Recommendations

We can recommend cost-effective materials best suited to your well environment, utilizing our extensive database of qualified proprietary materials that exceed NACE MR0175 standard guidelines.

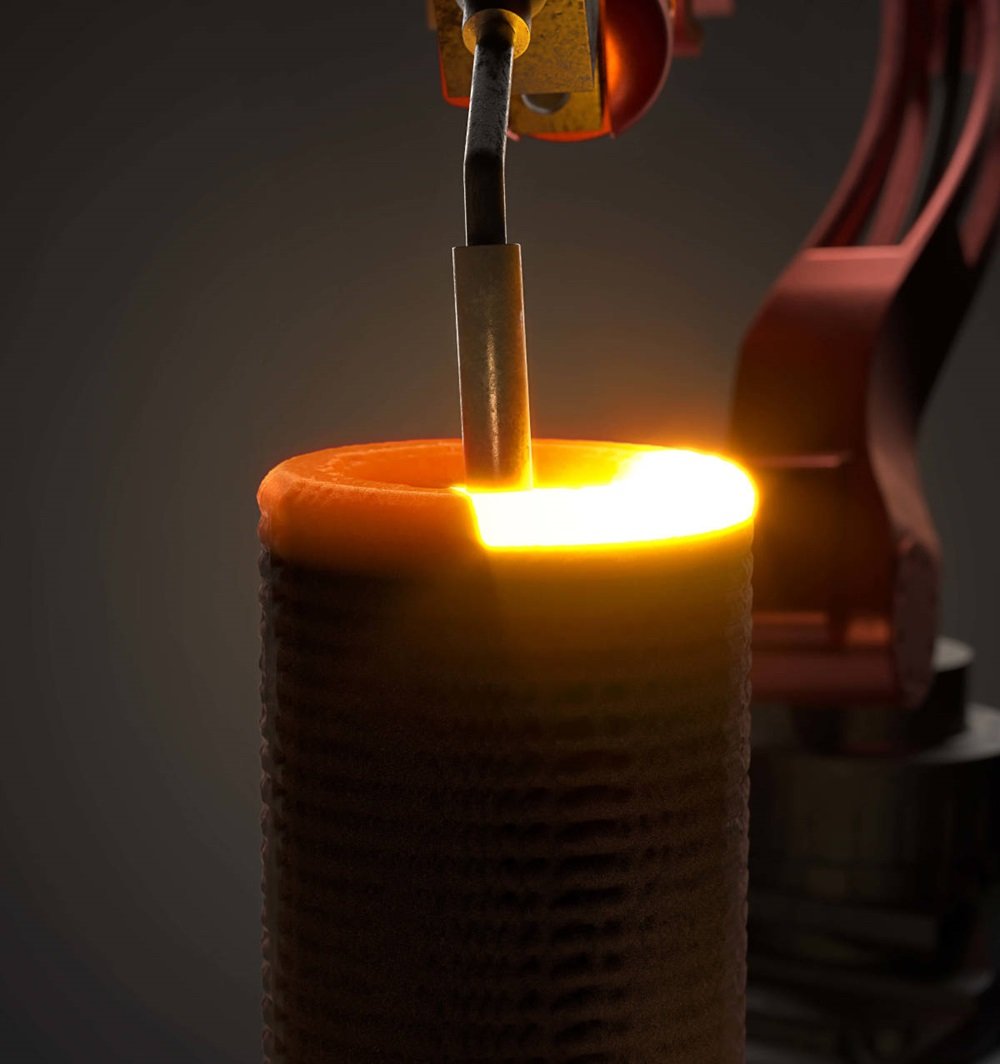

Advanced Testing Facilities

Our dedicated testing facilities offer a wide range of corrosion tests, from standard NACE tests to advanced techniques like polarization curves for rapid material screening, autoclave devices for HPHT conditions, and hydrogen permeation techniques to understand hydrogen behavior in materials. This allows us to conduct comprehensive qualification programs to evaluate properties such as Sulfide Stress Cracking (SSC), Stress Corrosion Cracking (SCC), and mass loss resistance of our products.

By leveraging our expertise and state-of-the-art facilities, we aim to support you in achieving optimal well design and performance.

Well Design Softwares

Advanced Well Design and Thermal Analysis

Our advanced well design and thermal analysis services encompass:

- Flow and Heat Transfer Simulation: Models the dynamics of flow and heat transfer during drilling operations.

- Casing Load Analysis: Evaluates casing loads and behavior under complex mechanical and thermal loading conditions.

- Completion, Production, and Stimulation Simulation: Simulates fluid and heat transfer during these stages.

- Tubing Load Analysis: Assesses tubing loads, movements, and thermal loading conditions.

- Annular Pressure Buildup (APB) Prediction: Forecasts pressure and volume changes due to APB.

Well Design Analysis

Our well design analysis tools provide a comprehensive suite of features to enhance the well planning process:

- Rapid Development of Accurate Casing Design Scenarios: Quickly creates precise casing design scenarios tailored to your project needs.

- Seamless Drag-and-Drop Functionality: Effortlessly transfer casing strings along with all associated loads and relevant data between designs, improving workflow efficiency.

- Completion, Production, and Stimulation Simulation: Simulates fluid and heat transfer during these stages.

- Automated Cost-Effective Design Generation: Automatically produce the most cost-efficient casing designs based on predefined load parameters, ensuring optimal resource use.

- Adherence to Industry Standards: Ensures designs comply with API TR 5C3 and API RP 1111 guidelines, guaranteeing adherence to industry best practices and regulatory standards.

Catalogue

Our catalogue feature allows to:

- Share between well design softwares

- Import desired product data:

- Create and personalize your catalogue

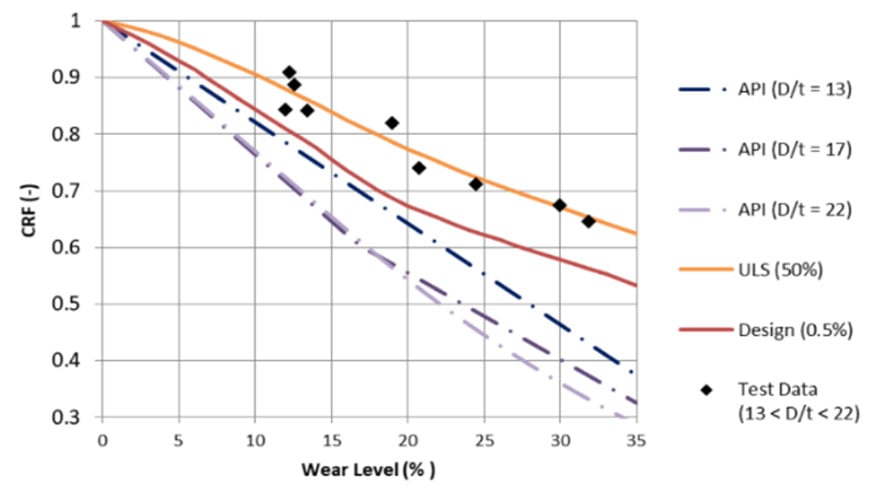

Performance Post-Casing Wear

The second phase involves developing tools to apply correct derating to the pipe body and connections, enabling accurate repetition of the well design simulation. These tools aim to enhance client confidence in the products, though they do not serve as a product guarantee.

During the well design stage, end users typically estimate the maximum material loss the selected casing can endure while remaining within operational limits. They run simulations to estimate wear on each section, using software with soft-string and/or stiff-string models. These software tools vary in accuracy, depending on the input data and models used.

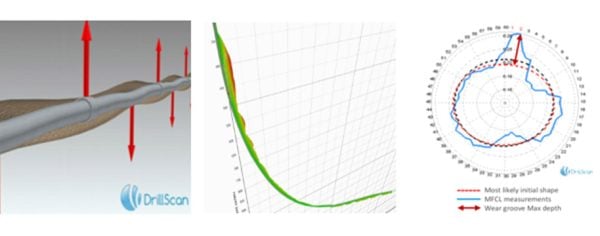

To be effective, a casing wear model should address the following key questions:

- Contact Points: Where are the contact points between the drill string and the inner well along the casing?

- Friction Work: How much friction work is occurring at these contact points?

- Wear Factors: What are the actual wear factors determining the volume loss?

The results should closely reflect reality. Therefore, operational calibration needs to be performed during model building to improve confidence in the results and increase the success rate.

To support customer requests, Vallourec has integrated casing wear modeling software, such as DrillScan, into our well design portfolio. While determining the extent of wear (“how much”) is an essential first step, it is part of a comprehensive program aimed at ensuring the reliability and efficiency of well designs.

Documents & Resources

Helping our customers find the right products for their needs is our daily commitment. For one customer, we helped reduce the total weight of a string for non-sour gas. Our design saved 10% in weight and in costs while maintaining safety above requirements. The new design also increased the clearance in the open hole for the cement job.

Discover our Solutions

More information