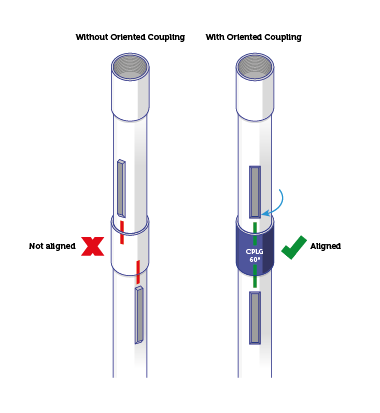

Tubular Orientation Services by VAM® Field Service

VAM® Field Service technicians can provide Assembly Orientation either at the workshop or on-site at the rig. This service ensures precise alignment of various completion assemblies. As wells become increasingly complex with numerous control lines and connected assemblies, or when avoiding string rotation while landing the hangers is necessary, the orientation service supports your operations. It ensures optimal alignment while maintaining the integrity of the entire string.