VAM® Field Service: Expert Oilfield Services for Premium Connections

VAM® Field Service delivers high-value oilfield services that ensure the integrity, reliability, and performance of your running operations on the rig. With more than 180 certified technicians across 19 global service centers, we provide responsive onsite support, precision tubular inspection, and comprehensive running services that reduce non-productive time and enhance well integrity.

Why Choose VAM® Field Service for Your Oilfield Services

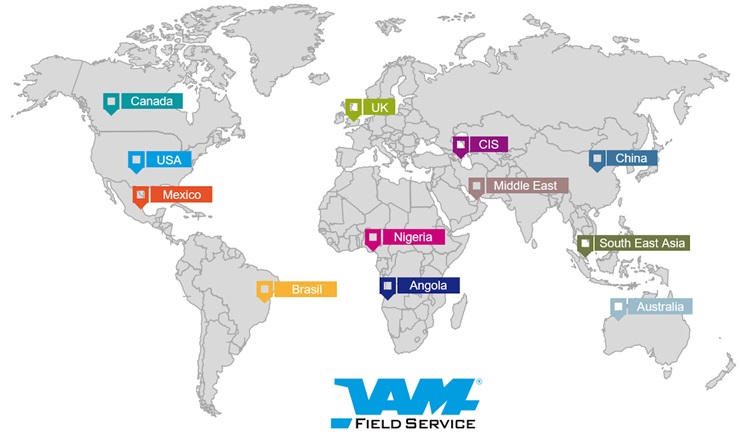

A Global Network of Certified Experts

Our 180 highly skilled technicians are based at 19 service centers worldwide, enabling rapid deployment to rigs, pipeyards, and customer facilities. Each technician is trained and certified to deliver consistent, high-quality support, regardless of region or operating environment. Through a range of services from mill to well, VAM® Field Service guarantees quality and performance for operators using VAM® products.

No one knows VAM® connections better than VAM®

VAM® Field Service provides deep technical knowledge of VAM® connection performance, make-up, and quality control. This expertise translates into safer operations, fewer rejects, and higher well integrity on your oil and gas projects.

Our Oilfield Services Portfolio

From pipe yard to rig-site supervision, VAM® Field Service delivers end-to-end oilfield services that support each stage of tubular deployment, handling, and management. You get a single, trusted partner to ensure your tubular equipment performs exactly as expected.

Rig Site Services

Expert support at the rig site to ensure safe and efficient running of tubular equipment

- Running supervision

- Deck inspection

- Loading/off-loading supervision

- Thread inspections – rig-ready and rig return

- Rig preparation

Pipeyard & Stock Management Services

Optimized yard operations and digital tools for inventory control and QHSE compliance

- Pipeyard management

- Digital stockyard management

- Collaborative planning

- QHSE best practices

- Yard design and audits

- Digitalization of stockyard management

- StockAssess

Assembly & Workshop Services

Specialized assistance for sub-assembly make-up, calibration, and compliance with VAM® standards

- Sub-assembly makeup & repair

- Supervision of assembly make-up

- Calibration checks

- Make-up process qualification

- Workshop audits

- Bucking unit qualification and calibration (TSLI 440 compliance)

- Low-torque soft seal pressure test fixture rentals

Technical Training & Remote Assistance

Obtain best practices and remote assistance on VAM® connection running

- VAM® Academy: training and assessment for engineers

- Embedded VAM® Support: VAM® Field Service embedded in your team on-site to ensure things run smoothly

- Licensor Technical Representative: quality control for VAM® licensees

Supported by Digital & Innovative Tools

Advanced solutions to improve efficiency, traceability, and decision-making

- TallyVision for real-time tally management

- Data analytics for operational insights

- Pre-Installed Cable Protector for enhanced safety

- Prime Mapping for optimized well design planning

A specific project? Need VAM® Field Service assistance? Let’s talk about it!

Documents & Resources

News

VAM® Field Service Middle East proudly announces its successful achievement of the prestigious API Specification Q2 certification, marking a significant milestone in service quality and operational excellence.

VAM® Field Service (VFS) has now monitored the torque turn of one million feet of OCTG casing with zero safety incidents or downtime for the rig over the past two years. The team’s exceptional performance sets a new standard for operational excellence in the fast-paced oil and gas industry, where safety and efficiency are paramount.

A VFS technician assisted a customer after sub-assembly pressure tests at a third-party workshop resulted in recurring leaks and damaged threads. He audited the workshop, performed the qualification of the horizontal make up unit, supervised the assembly make-up and replaced metal-to-metal TCP with low torque soft seal pressure test fixtures. The result: > zero leaks, > a reduction of costly and repetitive tests and > no need to recut damaged threads.

Discover our solutions

More information