Delphy Hydrogen Storage

Hydrogen storage is a key challenge for scaling renewable energy supply. Delphy is Vallourec’s market-ready underground hydrogen storage solution, capable of storing up to 100 tons of hydrogen gas vertically. Engineered to combine high-pressure performance, minimal surface footprint, and industry-leading safety, this turnkey solution has already been certified by Bureau Veritas and DNV.

Revolutionizing Hydrogen Storage

As industries, transport systems, and energy networks shift toward renewable and low-carbon hydrogen, the ability to store hydrogen safely, efficiently, and at scale has become essential.

Delphy is Vallourec’s market-ready underground hydrogen storage solution, capable of storing up to 100 tons of hydrogen gas vertically. Engineered to combine high-pressure performance, minimal surface footprint, and industry-leading safety, this turnkey solution has already been certified by Bureau Veritas and DNV. Delphy provides project developers with a proven, robust, and flexible storage architecture that can be deployed virtually anywhere.

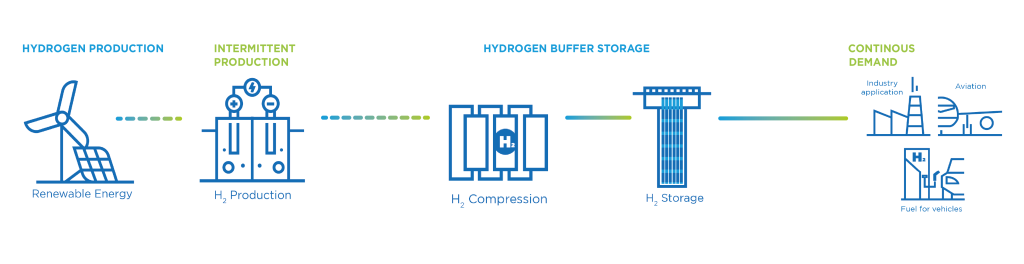

Why Hydrogen Storage Is Critical for the Energy Transition

Hydrogen plays an increasingly strategic role in decarbonizing hard-to-abate sectors such as steel, long-haul transport, chemicals, refineries, and power generation. However, hydrogen production often comes from intermittent renewable sources such as wind and solar, leading to fluctuations in output. To maintain reliable supply and support the growth of hydrogen ecosystems, sufficient storage capacity is essential.

Effective hydrogen storage enables:

- Buffering renewable electrolysis during periods of low production

- Steady deliveries to end-users (offtakers), avoiding disruption and downtime from intermittent H2 production

- Peak shaving to stabilize supply during demand spikes

- Smoothing distribution cycles for hydrogen mobility

- Increasing resilience and energy security for industrial users

- Optimizing project economics by decoupling production and consumption

Yet, conventional above-ground storage solutions can face major limitations, including large land requirements, strict safety distances, visual impact, and rising costs as capacity scales.

Delphy addresses these challenges by taking hydrogen storage underground — where it becomes safer, more compact, and far easier to scale.

The Technical Challenges of Hydrogen Storage

Hydrogen is a promising energy carrier, but it is also uniquely demanding from a materials and engineering standpoint. To build a storage solution that is both safe and practical, several challenges must be overcome.

Low Density

Hydrogen’s low volumetric energy density means that meaningful quantities must be stored at high pressure. Traditional above-ground racks or tanks can require large surface areas as capacity grows, which impacts land use, cost, and siting feasibility. Geological storage, such as salt caverns or depleted gas reservoirs, offers a cost-competitive approach for storing vast quantities of hydrogen. However, it necessitates suitable geology in proximity and around 5-7 years for construction.

Vallourec’s response lies in crafting high-pressure vessels that occupy minimal space, optimizing storage without compromising efficiency.

Hydrogen Leakage Risk

Because hydrogen molecules are extremely small, it is more prone to leakage, posing a challenge for containment and safety. Vallourec counters this with hydrogen-tight systems, ensuring minimal loss and maximum containment reliability.

Material Embrittlement

Hydrogen can cause mechanical degradation in standard steels, a phenomenon known as hydrogen embrittlement. Vallourec tackles this challenge by employing optimized hydrogen-resistant metallurgies, safeguarding the integrity of storage materials and prolonging their longevity.

Flammability Concerns

The flammability and explosivity properties of hydrogen often lead to concerns about storage safety. To address this perception, Vallourec develops storage solutions engineered with high safety-performance, assuring reliability and mitigating potential hazards.

Introducing Delphy: Vallourec’s Underground Hydrogen Storage Solution

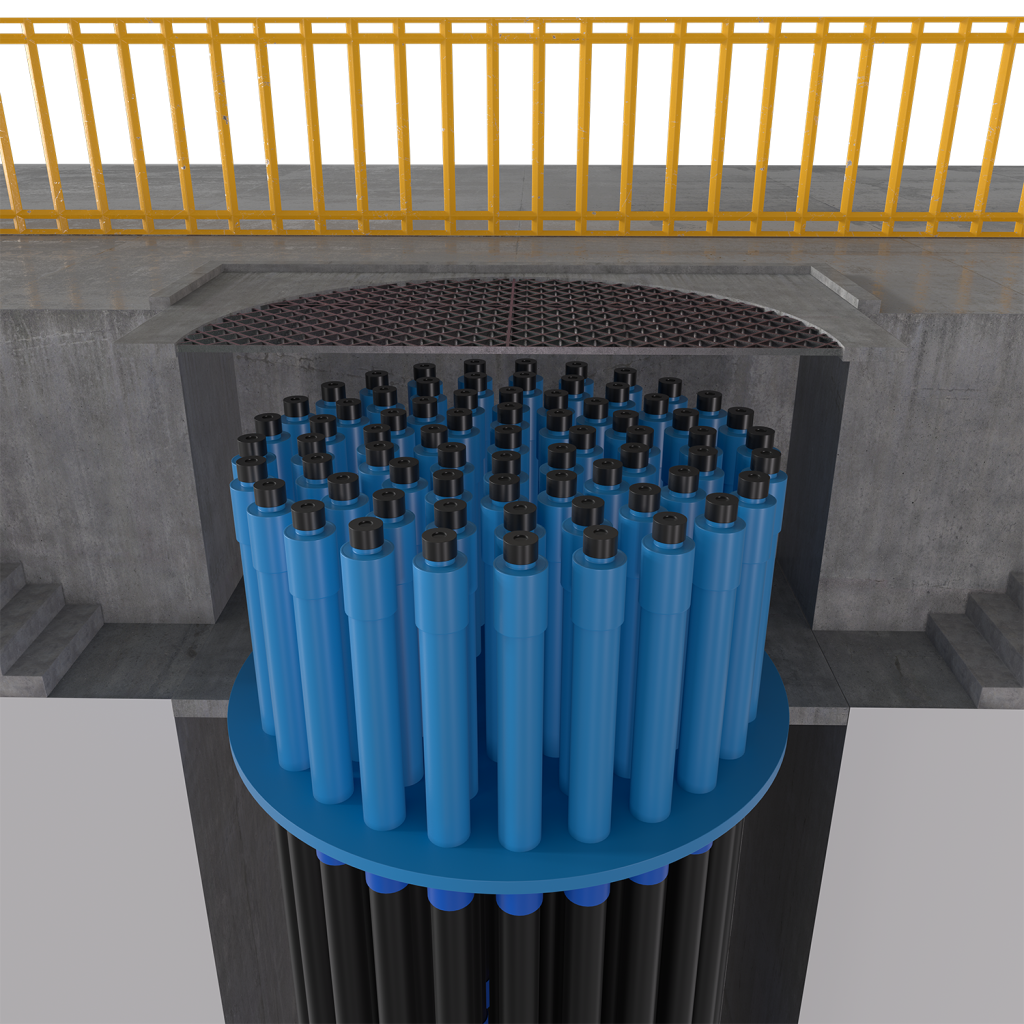

A world first, Delphy enables the storage of 1 to 100 tons of hydrogen under maximum safety conditions. Thanks to its minimal footprint, this vertical system – extending up to 100 meters underground – meets the challenge of complex and demanding industrial environments.

It targets both green hydrogen producers and industrial players such as synthetic fuel producers (e-SAF, e-methanol), green ammonia producers, steelmakers, refineries, and fuel cell technology developers.

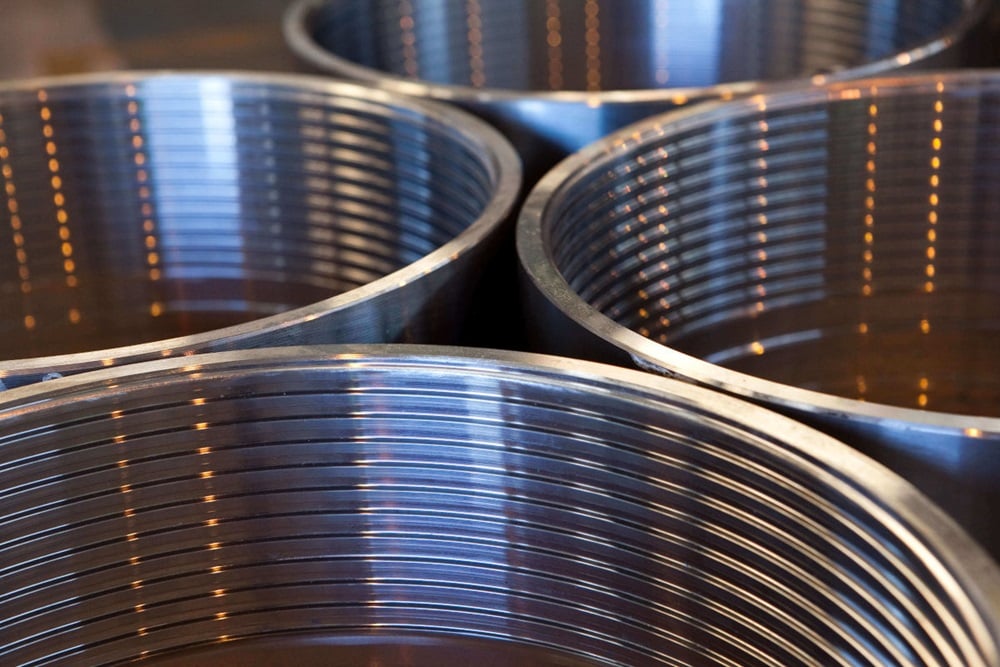

Hydrogen-Resistant Metallurgy

Hydrogen is pressurized and injected into hydrogen-resistant strings lowered into a vertical underground cavity using traditional civil works technologies.

Delphy uses hydrogen-resistant steel grades developed through Vallourec’s metallurgy expertise. These materials are specifically engineered to maintain mechanical integrity under high-pressure hydrogen exposure. Delphy is engineered and certified to operate safely at high pressures — up to 500 bar — depending on the customer’s needs.

Additionally, Delphy uses Vallourec’s premium, gas-tight connections, which are designed to maintain sealing integrity under high pressure and withstand thermal and mechanical cycling. This combination ensures long-term safety and performance over the operational life of the installation.

Minimal Surface Footprint

Instead of expanding horizontally across valuable land, Delphy goes vertically underground, drastically reducing the surface footprint while delivering safe, robust, and scalable storage capacity.

By reducing the surface footprint to a minimum, it is ideal for:

- Space-constrained industrial sites

- Hydrogen refueling stations

- Urban or semi-urban projects

- Sites with strict visual impact rules

This compact footprint helps reduce land acquisition costs and simplifies environmental and stakeholder approvals.

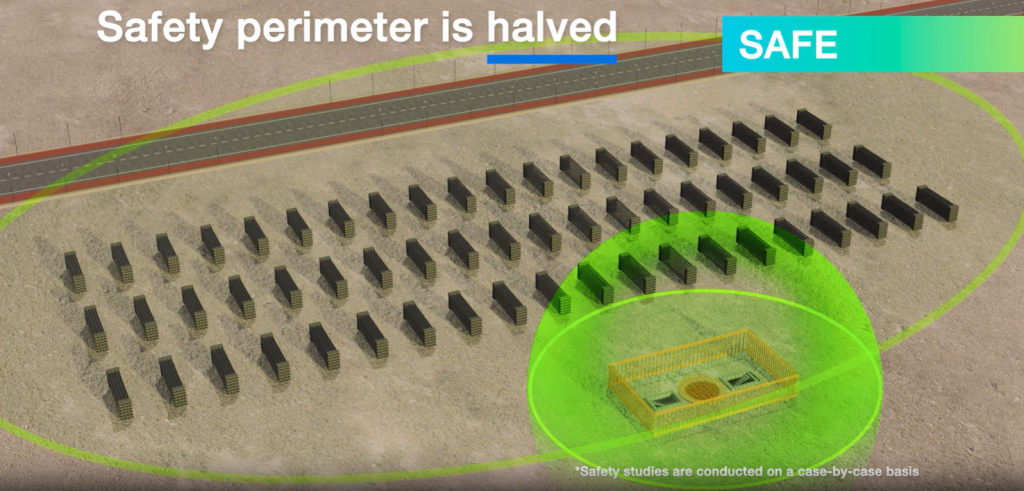

Highest Safety Performance

Safety perimeter is halved

Delphy’s underground design, combined with its minimal footprint, significantly lowers risk exposure compared to traditional above-ground storage solutions. By leveraging Vallourec-validated materials and connections, the probability of hydrogen leaks during storage is greatly minimized. In addition, the system is engineered with advanced passive and active safety features to ensure maximum protection.

A comprehensive risk analysis and qualification program was carried out in collaboration with independent expert DNV. In 2025, the complete Delphy system was officially qualified according to DNV-RP-A203 standards. Furthermore, Delphy obtained a Certificate of Conformity for its pressure equipment from Bureau Veritas.

Flexible & modular designs to optimize OPEX & CAPEX

Delphy’s project design is fully customizable, adapting to the targeted storage capacity and pressure level, the space available or the optimal depth based on local soil condition.

Additionally, these pipe strings provide a scalable solution, allowing for the easy expansion of the hydrogen storage capacity as the project grows. With the ability to add or remove pipes as needed, Delphy can adapt to changing requirements and ensure the efficient utilization of storage space. By adding more pipe strings over time, the project can incrementally increase its capacity, minimizing upfront costs while maintaining flexibility for future expansion.

As a part of the advanced technology qualification process, in 2023 Vallourec built a fully functional Delphy technology demonstrator in Aulnoye-Aymeries, France.

This demonstrator was meticulously designed to comprehensively test and validate various facets across the technology and asset lifecycle. Evaluations of design, construction, installation, storage functions, safety measures, were carried out. Additional tests as well as monitoring and maintenance activities are still taking place.

Guided visits of the demonstrator can be organized.

Watch Delphy’s Demonstrator Construction Story

A buffer hydrogen storage system is essential to ensure continuous e-SAF synthesis, compensating for grid fluctuations and renewable power intermittency. For example, a 245 tons-per-day e-SAF plant might require approximately 10-20 tons of buffer hydrogen storage to maintain stable operations. The Delphy hydrogen storage solution is specifically designed to address the unique challenges of e-SAF production.

Contact our experts

Reach out to us for an in-depth conversation regarding large-scale hydrogen storage for your projects. When is your project slated for? Join us to engage with our experts, discussing your storage requirements and finding the most fitting solutions for your project!

Frequently Asked Questions (FAQ)

The price of Vallourec’s Delphy large-scale hydrogen storage system is on par or below the price of legacy overground trailer-type hydrogen storage systems. For a formal technical-commercial proposal, please contact your Vallourec representative.

– Quantity of hydrogen stored;

– [Optional] Geographical location, if known;

– [Optional] Inlet and output flow rates, if known;

– [Optional] Output pressure requirements, if any;

1-100 tons.

Vallourec’s Delphy hydrogen storage system stores between 1-100 tons compressed hydrogen in its standard configuration. Customers requiring more than 100t H2 should contact a Vallourec representative for a customized offer.

200-350 barg in standard configuration. Higher pressures are available on request, up to 1,000 barg, for instance for HRS applications.

Up to 100 meters in depth (328ft).

For projects that require construction of multiple wells, there is flexibility to construct wells in a joint-up fashion or separately. The exact configuration of the civil works scope will be determined at the FEED or at the detailed engineering stage. Contact your Vallourec representative for more information.

Twelve (12) months from the Purchase Order date.

The system is delivered in a ‘flange-to-flange’ turn-key configuration. The main component of the scope are:

-Hydrogen-resistant VM110SS pipes and hydrogen-tight VAM® 21 connections;

-Containment cavity up to 100 m deep;

-Auxiliary systems, e.g. piping, control, instrumentation, monitoring, ESD (emergency shutdown) systems;

-Long-Term Service Agreement (LTSA);

20 years.

Documents & Resources

This collaboration focuses especially on hydrogen storage, where the companies have a complementary product and services offering. Together, Vallourec and Geostock can support the full range of storage needs of the green hydrogen value chain.

Vallourec announces the official qualification of Delphy, its vertical gaseous hydrogen storage solution, by DNV.

This page contains practical information about the visit to the demonstrator site. The goal of this info pack is to assist our customers and partners in planning their visits to the demo site, in terms of logistics, agenda, itinerary planning, etc.

Vallourec is revolutionizing hydrogen storage with its innovative underground vertical system.

By Pierre Martin, Eric Verger, Pierre Mauger, Alvaro Rodriguez, Laurent Boufflers, Anthony Lasjournades, and Nora Brahmi, at Vallourec, presented at the SPE Asia Pacific Oil & Gas Conference and Exhibition in Adelaide, Australia on 17 - 19 October, 2022.

By Florian Thebault and Vincent Designolle, presented at Abu Dhabi International Petroleum Exhibition & Conference (ADIPEC) in Abu Dhabu, UAE in November 2022.