Environmental Product Declaration

Company Description

As of January 1st, 2024, Vallourec facilities included:

- 2 steel mills, including an electric arc furnace in the United States and a blast furnace and electric arc

furnace in Brazil; - 8 tube mills across Europe, the United States, Brazil and Asia;

- 23 finishing units;

- A group of forest assets, an iron ore mine and a pelletization plant in Brazil.

Vallourec has an annual worldwide production capacity of 2.1 million tons of tubular products.

Detailed Product Description

Vallourec provides a wide range of cutting-edge steel solutions, as well as value-added digital solutions.

This combined offer helps customers meet their operational challenges while prioritizing safety.

The Group’s portfolio includes:

- one of the most extensive ranges of seamless tubes in the world, including sizes and proportions

(length, diameter, thickness) of up to 457 millimeters in outside diameter (OD), and a variety of more

than 250 steel grades (high-grade and low-grade carbon steel alloys, stainless steels, nickel alloys, etc.); - world-renowned premium connections, including VAM® connections and accessories;

- specialty tubes;

- a complete offer of innovative and digital services.

| Outside diameter (OD) | Wall Thickness (WT) | Yield Strength (YS) | Grades | ||

| PLP | From 2.375” (60mm) to 18” (457mm) | From 0.2” (5mm) to 4” (100mm) | From 245 to 555Mpa | API 5L up to X80 DNV-ST-F101 up to DNV SMLS 555 |

|

| OCTG | From 2 3/8’’ to 18 5/8’’ | Casing: up to 27/28mm Sleeve blanks: up to 45mm |

From 55 to 150 ksi | API standards (API 5CT) High collapse High strength Sour Service | 13CR and S13CR Corrosion-resistant alloys (including Nickel-based, Austenitic, Duplex, Super Duplex) |

| Industry |

Circular: 21.3 to 406.4mm Square: 50x50 to 300x300mm Rectangular: 60x40mm to 406.4x203.2mm |

Circular: 2.9mm to 50mm Square: 3.2mm to 20mm Rectangular: 3.2mm to 20mm |

Circular: From 30 to 125ksi Square: From 30 to 70ksi Rectangular: From 30 to 70ksi |

Basic Structural and Mechanical Grades and Multicert® series Engineering Grades Forterior® and Spirafort® series Advanced Engineering grades: Avadur® series and Bearing grades, alloyed heat treatable steels, case hardening steels, unalloyed heat treatable steels Offshore grades Oceanfit® series Fine-Grain High Strength Grades FineXcell® series Ballistic Protection Grades Durascilt® series |

|

Calculation Rules

Upstream Process | External raw material supply

Upstream processes cover all operations of Vallourec’s suppliers for the procurement of raw materials and energy carriers that are then used in the company’s operations, such as:

- Steel billets, bars, ingots and tubes;

- Ferroalloys;

- Scrap;

- Other raw materials feeding the pelletizing plant, blast furnaces and steel mills, such as steel scrap, pig iron, coke, coal, lime, limestone, graphite, etc. – all supplied for Youngstown (USA) and Jeceaba (Brazil) integrated sites with steel mills.

The environmental impacts of raw materials and energy carriers are assessed from cradle to Vallourec’s gate, and cover in particular:

- Extraction and/or mining and/or collection, sorting and

processing; - Process emissions resulting from the purchase of pellets,

pig iron, steel and steel products; - Land management and wood carbonization for the production

of biomass charcoal, including CH4 emissions associated with

the purchase of biogenic pig iron; - Transportation from the supplier’s site to Vallourec’s gate.

The environmental impacts of the construction of power plants, such as the manufacture of solar panels or nuclear power plants that supply electricity to Vallourec is accounted for. Transportation and distribution losses are also included, as well as the upstream transformation of fossil fuels consumed by Vallourec.

Upstream Process | Internal steel making

Steel making can also be integrated as part of Vallourec’s operations, in the steel mills of Jeceaba (Brazil) or Youngstown (USA). Industrial processes include:

- Internal raw material manufacturing, such as iron ore extraction and processing, eucalyptus forest management, charcoal production and ore pelletization;

- Land management and wood carbonization for the production of biomass charcoal (in Brazil’s Florestal Eucalyptus forest) with CH4 emissions from charcoal carbonization kilns, and zero CH4 emissions from Vallourec’s innovative Carboval process;

- Process emissions related to chemical reactions in the pelletizing plant, blast furnace and electric arc furnaces;

- Internal transportation of raw materials and intermediate products (including iron ore, pellets and charcoal) to the pelletizing unit, blast furnaces and steel mills.

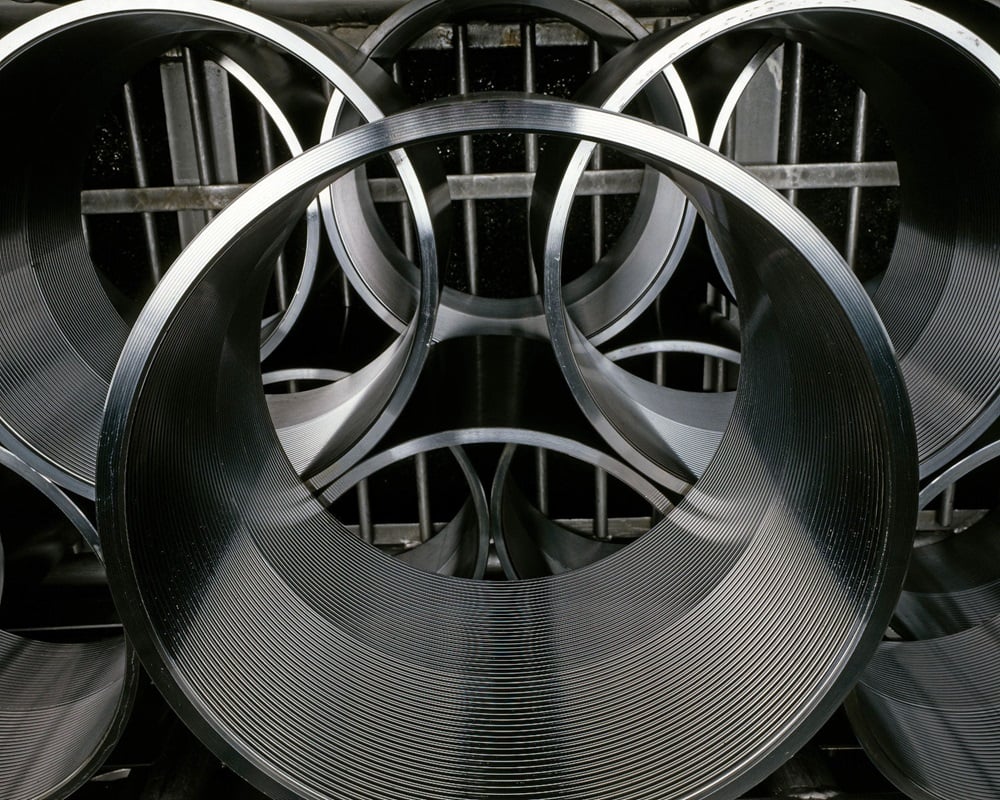

Core Process | Tube manufacturing

Tube making represents the last part of Vallourec’s process, which consists of:

- Rolling mills, transforming steel billets into hollow tubes;

- Heat treatment units, so that seamless steel products meet specification criteria;

- Finishing lines, with various applications such as threading, quality testing, painting, or coupling tube ends with plugs;

- Transportation of semi-finished tubes from one Vallourec mill to another;

- Electricity production, either through on-site solar panels, or diesel generators;

- Internal recovery, or treatment of the waste generated

by the manufacturing process; - Water treatment and recirculation, as the core process requires cooling and quenching.