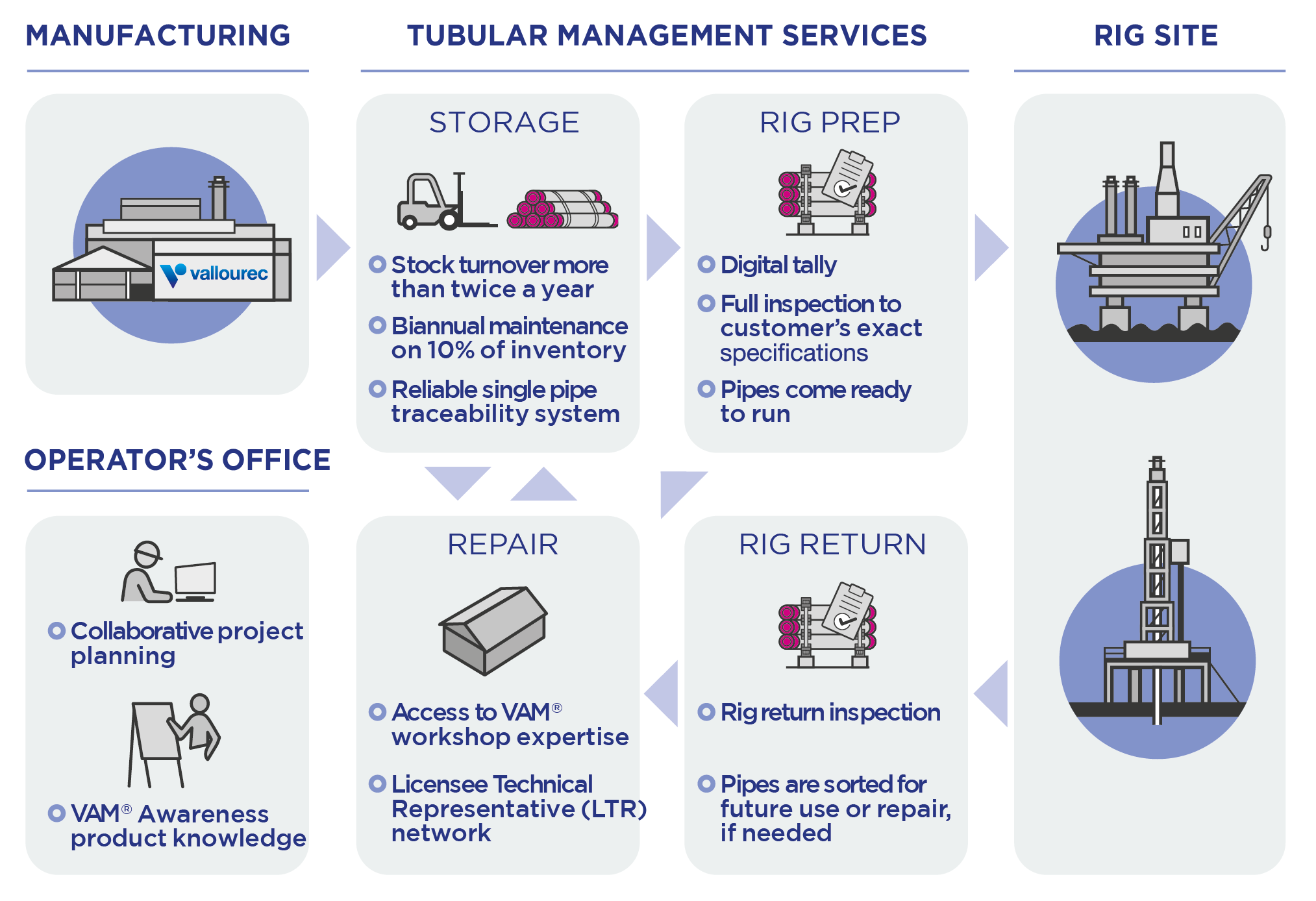

Tubular Management Services

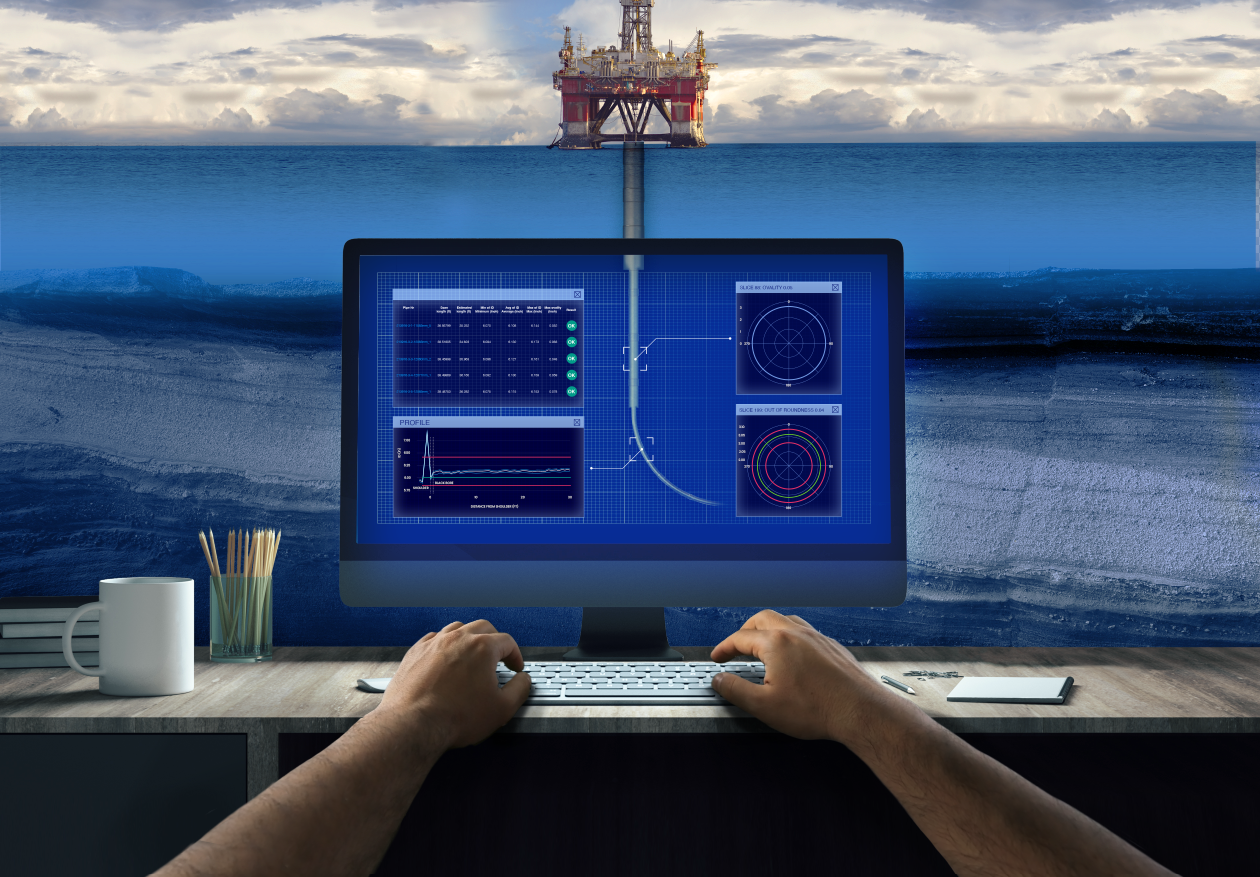

Reduce your operational expenditures and get full digital visibility on your stock and yard management thanks to our robust processes and digital traceability system.

Leveraging our expertise and 30+ years of experience, Vallourec’s Tubular Management Services help customers optimize pipe yard storage, transport to and from the rig, and inspection. Whether managing inventory at a customer yard, or at our own facilities around the world, our field and digital solutions streamline the most complex installations. Our aim is to ensure full reliability and traceability from yard to rig.