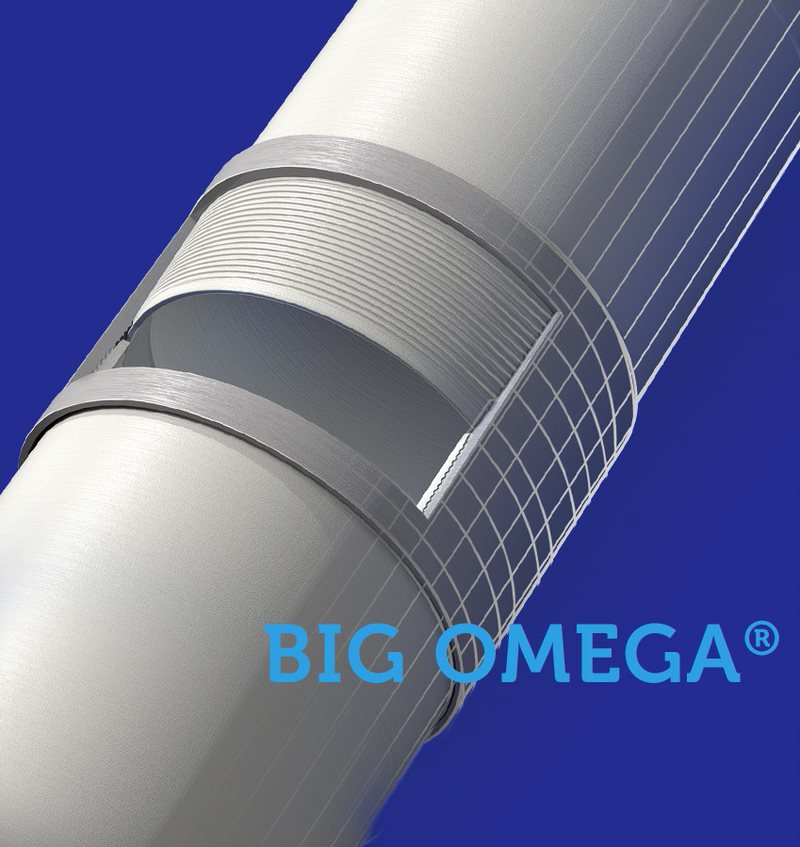

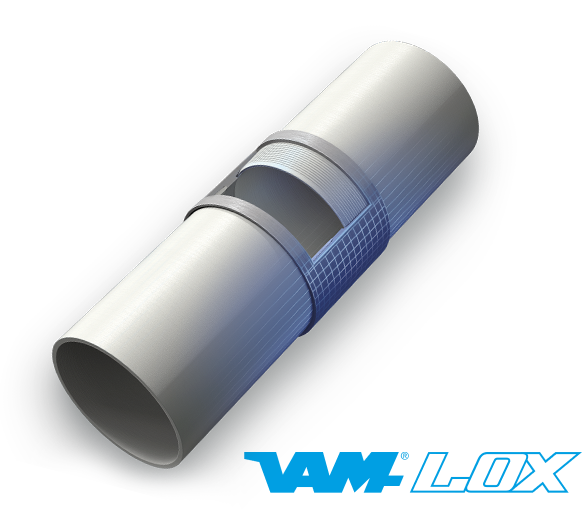

VAM® LOX

Lightweight and easy to run: your cost-effective premium surface casing

VAM® LOX is your valuable T&C alternative to weld-on connectors, ending welding operations and complex installation of anti-rotation devices! Thanks to a double-start thread design requiring only standard running equipment, VAM® LOX is easy and quick to run. Its metal-to-metal seal provides gas-tightness, including for high yield materials, ensuring integrity while optimizing the string weight of your most challenging wells.