PREON® box

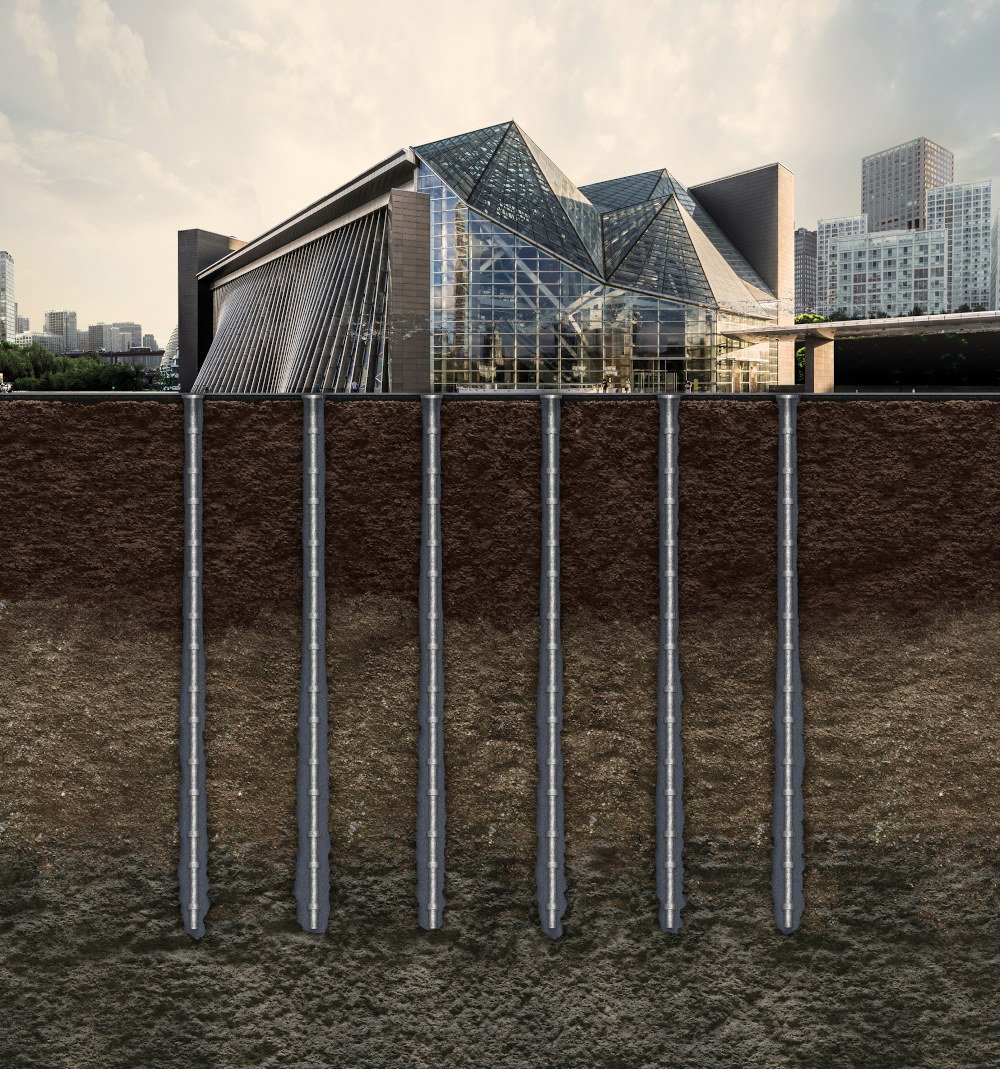

Structural Hollow Sections and software for column-free hall construction

PREON® box combines our Structural Hollow Sections with a software tool to drastically simplify the construction of diverse steel structure applications such as industrial halls or solar hangars and saves up to 30% in fabrication costs.