Automotive Bearing Tubes

To optimize safety and keep vehicles running smoothly, bearing tubes must be precise and seamless.

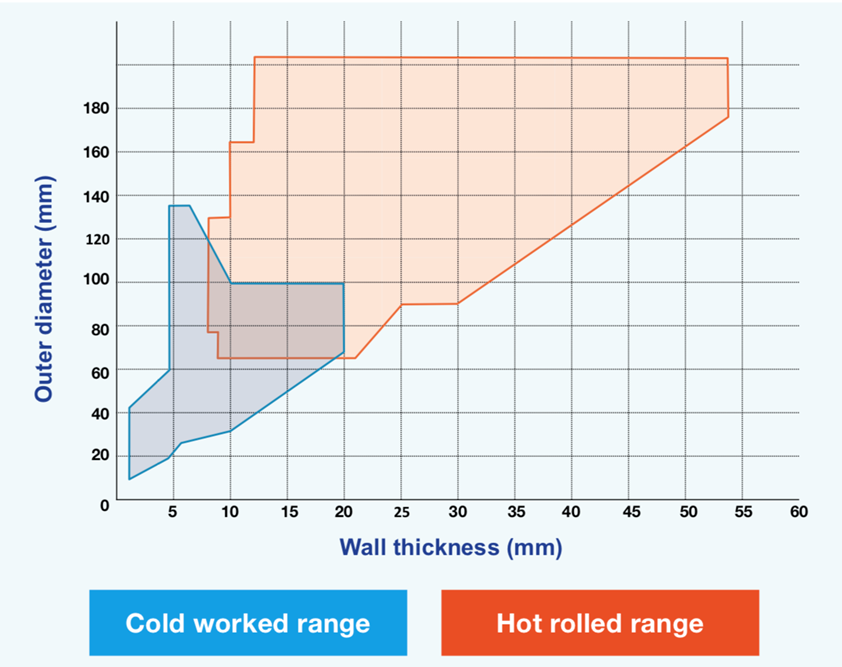

Our full range of bearing tubes and net-shaped rings, either hot or cold-rolled, are available with optional heat finishes, including peeling and cold-pilgering. Our Smartube line is a cost-effective solution that adapts to your manufacturing equipment and simplifies your supply chain logistics.