Best Fit

Using powerful digital technology, Best Fit provides full visibility on achievable Hi-Lo for any pipe brand, allowing you to anticipate welding operations and mitigate risks. Your teams can use the smartphone app to make faster fit-up decisions and maximize operational efficiency.

Benefits

Our Solution

Prediction of HiLo

Using unique pipe-end identification technology, our advanced algorithm provides a deterministic analysis of the data to accurately predict the HiLo resulting from all possible pipe-end combinations and anticipate operational constraints.

Intelligent Pipe Grouping

We can identify specific pipes for the critical zone (fatigue-sensitive zones) and segregate these from the rest. We then propose intelligent pipe grouping with tailored recommendations to maximize the compatibility of pipes on the firing line.

Best Fit App

Our mobile app allows welders on the firing line to instantly identify whether pipe-ends have full compatibility for welding, whether compatibility can be achieved with pipe rotation, or whether the pipe needs to be withdrawn temporarily from the firing line and then reintroduced into the firing line at a later moment. The mobile app is operated autonomously by your teams.

Live Pipe Data

An as-built digital tally of the line pipe construction is automatically generated in an easy-to-exploit format and alerts functionalities related to the cumulative pipe length not being within the optimum range.

It Work?

1- Each pipe end is tagged to ensure unique identification

2- Pipe end laser measurement anywhere, anytime

3- Analysis of all Hi-Lo

combinations

4- Recommendations

for faster fit-up

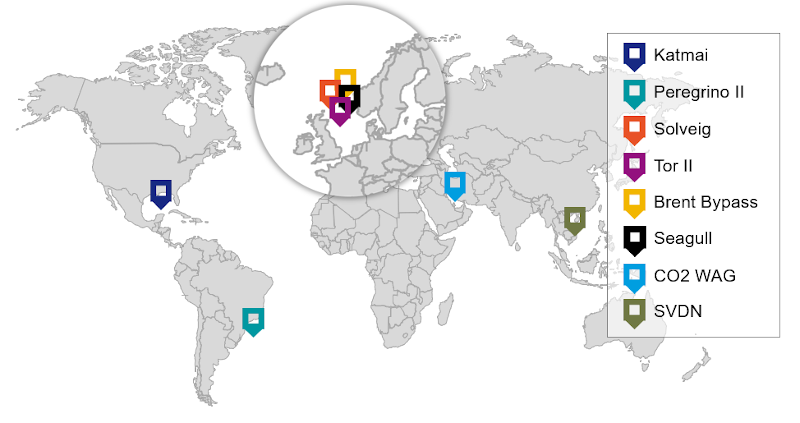

Track Record

30+ projects

10+ satisfied customers

> 50,000 high-quality welds

Onshore & offshore welding | Seamless & welded pipe | Field-proven benefits

Documents & Resources

Leverage digital intelligence to derisk your project & maximize welding effiency

Conclusions of Best Fit analysis performed on pipe end geometrical data and operational recommendations related to pipe management & fit-up one the firing line

Article published in the fifth issue of the Pipeline Technology Journal, November 2020.

Article published in World Pipelines magazine, April 2020 issue.