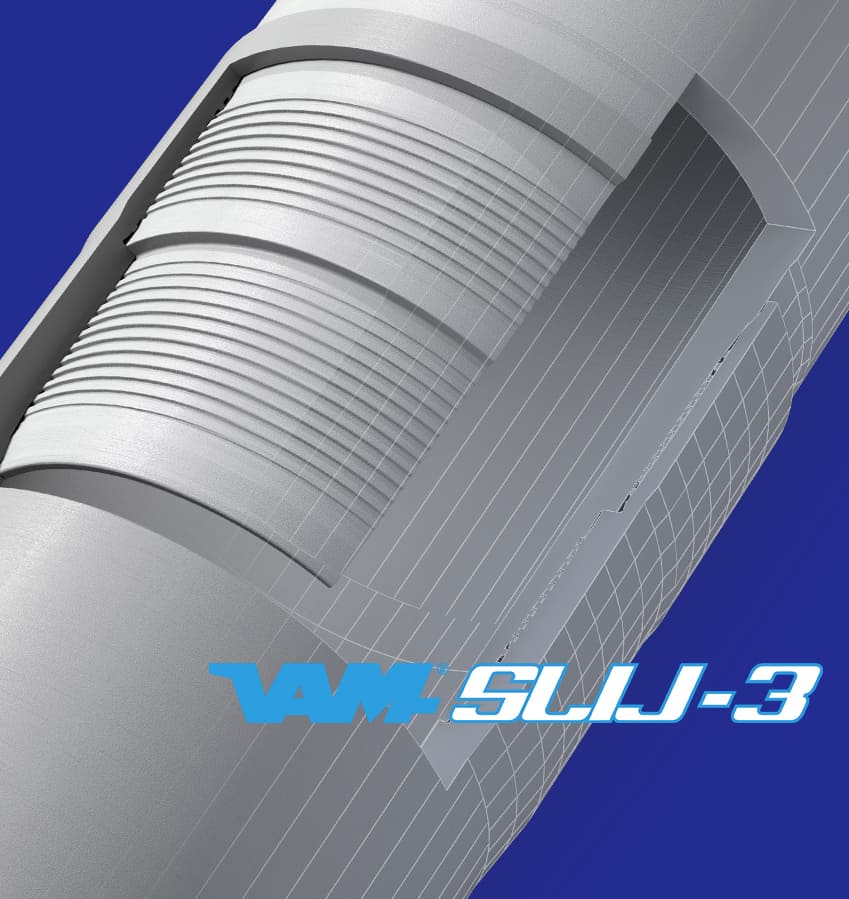

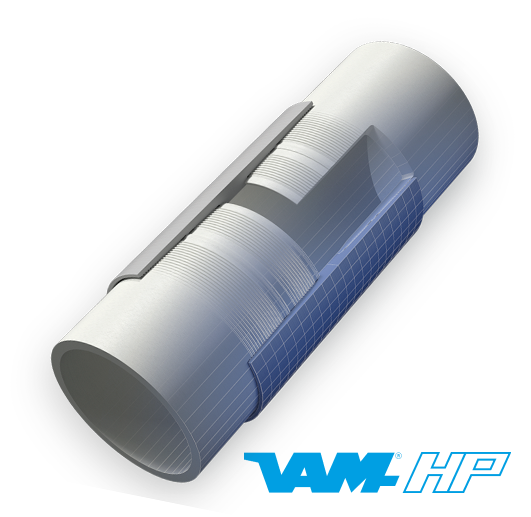

VAM® HP

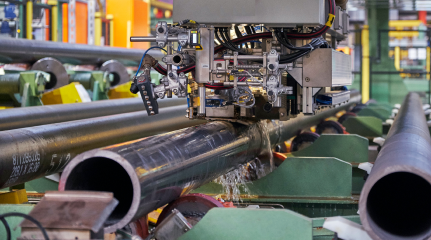

Premium performances connection for heavy wall pipes and extreme high pressure requirements

VAM® HP design is dedicated to resist the highest pressure loads for extreme conditions where high grade, heavy wall pipes are mandatory. It was specifically designed to overcome problems associated with annulus pressure build-up in HP/HT wells, using a dual gas tight sealing system to isolate internal and external pressure, and includes high clearance and high torque capacity to cope with the most challenging well conditions.