High Collapse

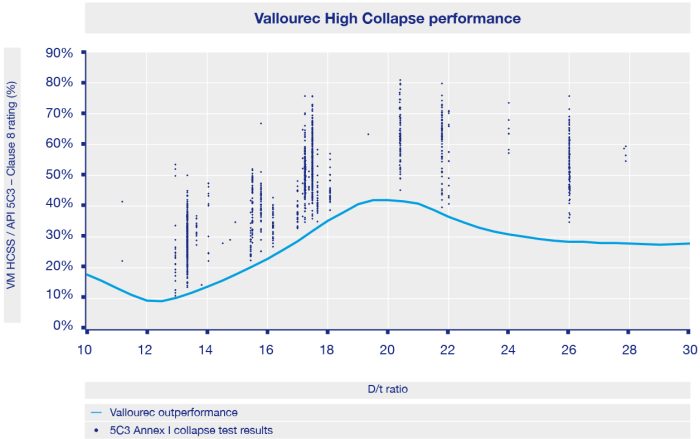

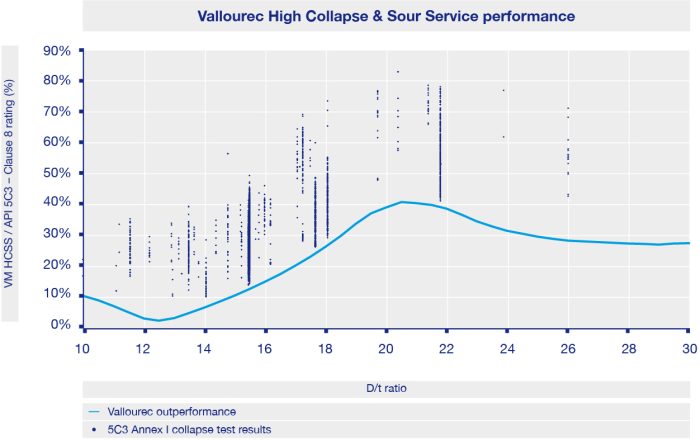

High Collapse pressure (or external pressure beyond standards) are typical of critical wells due to depth, formation or temperature (Annulus Pressure build-up). For decades, Vallourec has developed process controls and collapse models backed-up by thousands of test results to deliver high collapse ratings for best-in-class performances.

Benefits

Collapse is a failure mode where the wall of the pipe achieves important strain levels and caves due to the application of external pressure. This pressure can be associated to external formation pressure, displacement of the formation layers, high temperatures resulting in increased annulus pressure, among others.

API standard products can offer a limited collapse rating, often inadequate to operator’s drilling operations. Increasingly, enhanced collapse properties are required due to critical applications, such as extended reach drilling, deepwater or HPHT wells.

For many decades, Vallourec has developed a collapse resistant proprietary offer to meet the most challenging external pressure requirements. Thanks to their enhanced collapse resistance and superior mechanical properties, High Collapse grades enable slimer, lighter well designs, thus drastically reducing string cost.

Vallourec High Collapse offer is based on strict geometrical and mechanical property controls, as well as on a proprietary collapse model, while relying on thousands of physical test results; it represents the safest solution for the most demanding applications.

This superior collapse resistance is achieved through strict control of geometrical and mechanical properties during the manufacturing process. Our offering includes:

- API Enhanced Collapse grades, a cost-effective solution that meets medium severity collapse requirements;

- High Collapse grades, offering collapse rates up to 50% higher than API values due to their proprietary design and strict dimensional and mechanical properties

Product portfolio

| High Collapse | |

| Application | Critical Services |

| Low Strength | VM 80 HC |

| VM 80 HCS | |

| VM 80 HCSS | |

| VM 80 13CRHC | |

| VM 90 HCS | |

| VM 90 HCSS | |

| VM 90 13CRHC | |

| VM 95 HC | |

| VM 95 HCS | |

| VM 95 HCSS | |

| VM 95 13CRHC | |

| VM 95 13CRSSHC | |

| VM 100 HCSS | |

| High Strength | VM 110 HC |

| VM 110 HCMS | |

| VM 110 HCSS | |

| VM 110 13CRSSHC | |

| VM 125 HC | |

| VM 125 HCSS | |

| VM 125 HCESS | |

| VM 125 CYHC | |

| VM 130 HCMS | |

| VM 130 CYHC | |

| VM 140 HC | |

| VM 140 CYHC | |

| VM 150 CYHC |

Our High Collapse offer is available in the full range of outside diameter from 4 ½” to 26” from 80ksi to 150ksi, including special drift diameters and odd-ball sizes upon customer requirement.

All Vallourec proprietary High Collapse and High Strength grades are supplied with VAM® connections, fully validated against API RP 5C5:2017 / ISO 13679:2019 up to the pipe’s collapse resistance, hence providing a final product with fully demonstrated external pressure resistance.

Naming

The name of our High Collapse grades generally consists of three parts:

| YY | Collapse | High Strength | Sour Service | Sweet Service |

| HC | High Collapse | - | - | |

| HCS | High Collapse | - | w/o SSC testing | |

| HCMS | High Collapse | - | Mild Sour | |

| HCSS | High Collapse | - | Severe Sour | |

| 13CRHC | High Collapse | - | - | 13Cr |

| 13CRSSHC | High Collapse | - | - | Super 13Cr |

| CYHC | High Collapse | Controlled Yield | - |

High Collapse grades

Drillers are often confronted with sharp increase in collapse pressure requirements wile drilling through abnormal pressure zone such as salt layers. High Collapse grades are cost-effective solutions commonly used to replace standard API grades preventing against complex and heavy well design and assuring single external diameter and internal drift along the whole string.

The detailed description of each grade is given in a Product Specification. This document is available upon request.

| GRADES | MIN. YIELD STRENGTH (ksi) | MAX. YIELD STRENGTH (ksi) | MIN. TENSILE STRENGTH (ksi) | MAX HARDNESS MEAN (HRC) |

| VM 80 HC | 80 | 110 | 100 | - |

| VM 95 HC | 95 | 125 | 110 | - |

| VM 110 HC | 110 | 140 | 125 | - |

| VM 125 HC | 125 | 150 | 135 | - |

| VM 140 HC | 140 | 160 | 150 | - |

With several 100 ktons of High Collapse sales, our collapse ratings are field proven with pipes run on the most challenging drilling operations through pre-salt layers in deep-water projects in South America and Gulf of Mexico, critical HP/HT wells in North Sea, West Africa and Asia, among other.

High Collapse proprietary grades are fully compliant with API 5CT standard, they are designed based on proprietary model and using stringent dimensional and mechanical properties to reach collapse rating up to 50% above standard API grades, all backed-up by thousands of physical testing.

High Collapse products are available via our Connection Data Sheet website, for more detailed assessment and tailor-made solutions please contact our technical sales hub.

High Collapse grades in sour service environment

When drilling through H2S containing environments it become even more critical due to the risk of sulfide stress cracking and the consequent limitation of the yield strength of the production casings depending on the sour level of the reservoir. In those cases, special metallurgy and pipe manufacturing are requested to combine sour service and high collapse properties.

API grades are limited to 110ksi SMYS as well as with limited sour service properties. Vallourec has long history designing High Collapse & Sour Service products being able to offer HCSS grades up to 110ksi SMYS for unlimited H2S environment and up to 130ksi SMYS for mild sour environment.

| GRADES | MIN. YIELD STRENGTH (ksi) | MAX. YIELD STRENGTH (ksi) | MIN. TENSILE STRENGTH (ksi) | MAX HARDNESS MEAN (HRC) | NACE QUALITY CONTROL TESTING | SSC QUALIFICATION DOMAIN | |||

| INITIAL pH | ppH2S (bar) | METHOD A THRESHOLD(% SMYS) | METHOD D MIN K1SSC MEAN (ksi √in) | ||||||

| VM 80 HCSS | 80 | 95 | 95 | 22 | 2.7 | 1 | 90 | w/o | SSC Region 3 |

| VM 90 HCSS | 90 | 105 | 100 | 24 | 2.7 | 1 | 90 | w/o | SSC Region 3 |

| VM 95 HCSS | 95 | 110 | 105 | 25 | 2.7 | 1 | 90 | w/o | Unlimited H2S |

| VM 100 HCSS | 100 | 110 | 105 | 25.4 | 2.7 | 1 | 90 | w/o | SSC Region 3 |

| VM 110 HCSS | 110 | 120 | 115 | 30 | 2.7 | 1 | 85 | w/o | SSC Region 3 |

| VM 125 HCSS | 125 | 135 | 130 | 34 | 3.5 | 0.03 | 85 | w/o | 0.03 bar H2S / pH 3.5 |

| VM 130 HCMS | 130 | 140 | 135 | 35 | 4.5 | 0.014 | 85 | w/o | 0.014 bar H2S / pH 4.5 |

With several 100kT delivered over the last fifteen years to support critical deep-water projects in South America and Gulf of Mexico as well as HP/HT projects in North Sea area VM 125 HCSS is the most robust and field proven worldwide grade. Ultra-pressure wells, recognized to have complex design with very tight clearance, have evolved towards higher strengths and larger casing diameters to withstand higher loads and more stringent requirements. To address such high standards VM 130 HCMS grade has been specially developed combined with odd dimensions.

High Collapse products are available via our Connection Data Sheet website, for more detailed assessment and tailor-made solutions please contact our technical sales hub.

High Collapse grades in sweet environment

Under CO2 containing environments, commonly called sweet environments, carbon steel materials are subjected to severe general and localized corrosion. This loss of wall thickness can not only drastically reduce the service life of the string, but also severely compromise its mechanical resistance.

Under such conditions, martensitic (13CR) and super martensitic (13CRSS) stainless steel in combination with high collapse properties represent a good alternative to avoid CO2 corrosion in strings subjected to high mechanical loads.

| GRADES | MIN. YIELD STRENGTH (ksi) | MAX. YIELD STRENGTH (ksi) | MIN. TENSILE STRENGTH (ksi) | MAX HARDNESS MEAN (HRC) | CHARPY - MINIMUM ABSORBED ENERGY ON FULL SIZE SPECIMEN (J) | ||

| Transverse | Longitudinal | Testing temperature | |||||

| VM 80 13CRHC | 80 | 95 | 95 | 23 | 31 | 45 | 32°F (0°C) |

| VM 90 13CRHC | 90 | 105 | 100 | 26 | 20 | 30 | 32°F (0°C) |

| VM 95 13CRHC | 95 | 110 | 105 | 28 | 14 | 20 | 32°F (0°C) |

| VM 95 13CRSSHC | 95 | 110 | 105 | 28 | 80 | 100 | 14°F (-10°C) |

| VM 110 13CRSSHC | 110 | 140 | 115 | 32 | 40 | 60 | 14°F (-10°C) |

With several 10 ktons run in Middle East, these grades are particularly fitted to be used in string sections that are in permanent contact with the corrosive production fluid, while simultaneously subjected to high mechanical loads, as is the case of the production casing below packer and some tubing strings.

High Collapse products are available via our Connection Data Sheet website, for more detailed assessment and tailor-made solutions please contact out technical sales hub.

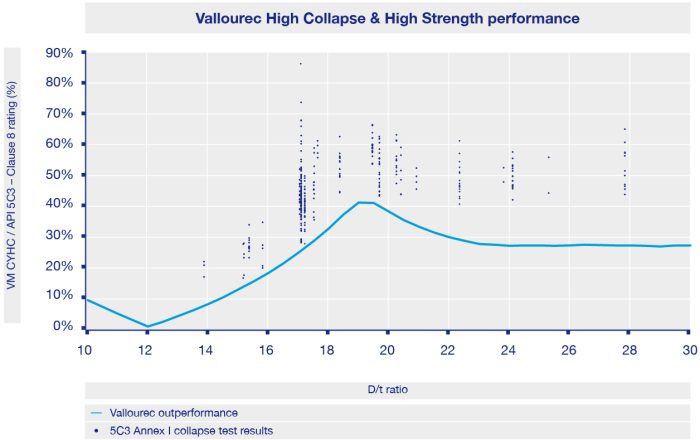

High Collapse and High Strength grades

As well depths increase, casing string exhibiting enhanced internal pressure resistance are commonly requested. The use of high strength materials, over standard API Q125 grade, has become the new standard for OCTG drilling operation.

For production and intermediate casings requiring enhanced burst properties combined with standard HC products, Vallourec has developed a wide portfolio of CYHC grades. They present tight yield strength range, limited hardness levels and improved toughness properties thanks to special chemistry design and robust heat-treatment process.

Vallourec offers a full range of CYHC products manufactured as per API 5CT standards and fully compliant to Q125 grade, except for VM 150 CYHC which exhibit improved yield strength range.

| GRADES | MIN. YIELD STRENGTH (ksi) | MAX. YIELD STRENGTH (ksi) | MIN. TENSILE STRENGTH (ksi) | MAX HARDNESS MEAN (HRC) | CVN - ABSORBED ENERGY MIN. AVERAGE FOR TRANSVERSE (JOULES) |

| VM 125 CYHC | 125 | 140 | 135 | 35 | 66 |

| VM 130 CYHC | 130 | 140 | 135 | 35 | 66 |

| VM 140 CYHC | 140 | 150 | 145 | 36 | 41 |

| VM 150 CYHC | 150 | 160 | 155 | 39 | 41 |

Proved sour service performances at elevated temperature!

Thanks to higher temperature levels the susceptibility sulfide stress cracking (SSC) of regular carbon steels is reduced. The top of the well is usually associated with the decrease of temperature and thus increase of hydrogen embrittlement. Therefore, the risk for SSC is higher at the top than at the bottom of the well.

As per table A.3 of NACE MR0175/ISO15156-2 standard, an API Q125 grade based on quench and temper heat-treatment process, chromium and molybdenum (Cr-Mo) chemistry and presenting maximum yield strength up to 150ksi is acceptable for sour service environment for temperatures higher than 107°C/225°F. However, there is a lack of details of minimum levels of Cr and Mo to reach such SSC resistance.

To cover this matter VM 140 CYHC grade has been qualified at 1 bar H2S partial pressure, 2.7pH and at 90%AYS which makes it suitable for these severe sour environmental conditions for temperature levels above 107°C/225°F. Moreover, SSC resistance of VM140CYHC grade has been verified under mild sour environment at lower temperature level. It has been qualified for temperature above 65°C/150°F at 0.03 bar H2S partial pressure, 5.0pH at 90%AYS.

VM 125 CYHC and VM 130 CYHC are suitable under severe sour environment for temperature level above 80°C/176°F.

What is collapse phenomenon?

Significant advances in drilling methods and technology have made it possible to drill wells in any situation by using specialized tools. However, some limitations remain, like casing design.

Wrong casing selection can lead to pipe collapse and drift loss, that could result in time loss and even loss of well control, putting the operation and personnel on the rig in danger

Casing used in critical applications such as Extended reach drilling, deepwater or HPHT wells are subject to level of loads not found in simple vertical wells, hence careful analysis of drilling and production scenarios and use of premium products is required.

Deep water wells are particularly affected by the annulus fluid expansion phenomena, since there is usually no direct access to bleed off the increase pressure in annulus. This could lead to casing collapse and to cement damage, causing zonal isolation problem and well control situation or production loss

Collapse loads are imposed by the pressure around and counteract by the pressure inside the casing, caused by the hydrostatic fluids inside and outside the pipe. Most severe collapse loads can be found:

- During drilling phases: if the casing is run empty or if a loss of circulation zone is encountered during the next phase interval (partial or full evacuation)

- During production phase on deepwater wells: if the well is subject to an Annulus fluid expansion issue resulting by increasing of temperature in closed annulus during well flowing.

In the industry, there are different models used to determine the collapse resistance of a tubular, value that will be used during well design. The current most important models, use the same approach for estimating the external pressure strength of pipes, considering D/t ratio and the yield strength as the main parameters:

- One elastic equation, valid for very high outside diameter to wall thickness ratios (D/t) (i.e. pipes with slender configuration). This equation predicts the moment of instability (buckling) before the material reaches the yield strength;

- One yield check equation, valid for very low D/t ratios (i.e. pipes with thick configuration). This equation checks whether the material reached the yield strength anywhere in the pipe;

- Some kind of transition equation(s) to predict what happen in between the previous situations.

Some examples of equations that use this approach are: Timoshenko, Clinedinst, historical API, Klever-Tamano and DNV (for line pipes).

There are however other mechanical and metallurgical aspects that, if not controlled, can quickly undermine the collapse strength of pipes. For example:

- ovality

- wall thickness

- eccentricity

- residual stress

- shape of the stress-strain curve shape (see schematic illustration below)

- steel chemistry

- process of manufacture

High Collapse Standards and Guidelines for OCTG

| Scope | Highlights | ||

| API 5CT | Casing and Tubing | This standard defines the product technical requirements and specifications of casing and tubing pipes used for oil wells in petroleum and natural gas industries.

Besides casing and tubing, it also includes pup joints, coupling stock, coupling material, and accessory materials. |

Although this standard does not does not define specific requirements for collapse resistant products, Vallourec proprietary grades are fully compliant with its specifications. Furthermore, API grades N80Q, R95, P110 and Q125 in PSL2 are the basis of Vallourec High Collapse grades |

| ISO 11960 | Petroleum and natural gas industries

- Steel pipes for use as casing or tubing for wells |

Being very similar in content and scope to API 5CT, standard ISO 11 960 also defines the technical delivery conditions and requirements for pipes, coupling stock, coupling material and accessory material for casing and tubing. However, this standard additionally describes specific requirements for High Collapse products on its annexes. |

The main requirements to manufacturers include having a methodology of establishing the collapse rating, having a documented validation procedure, and control and recording of parameters considered to be relevant for high collapse performance. |

| API 5C3 and ISO 10400 | Calculating Performance Properties of Pipe Used as Casing or Tubing

Petroleum and natural gas industries — Equations and calculations for the properties of casing, tubing, drill pipe and line pipe used as casing or tubing |

Both standards have very similar content in what regards collapse and have the normative Clause 8, which defines the calculations for determining the design rating, with and without axial loads, for tubulars based on historical API equations. | Its Annexes G and H propose models to obtain the design collapse ratings for non-API products. The former is purely based on statistics of direct collapse test measures. The latter is based on production quality data (such as wall thickness and ovality) The main limitation of these proposals is that the pipes are seen as part of a sample data, making inference about the population. The consequence is that the manufacturer nor the user have information about the rating and performance of single joints. |

Vallourec High Collapse methodology

Proprietary model

Vallourec has developed a Collapse Proprietary model able to calculate collapse rating based on pipe properties such as Yield Strength, Wall Thickness, Ovality, Eccentricity, Residual Stress. For those parameters, acceptable target ranges are defined at HC product design phase, and then controlled during production:

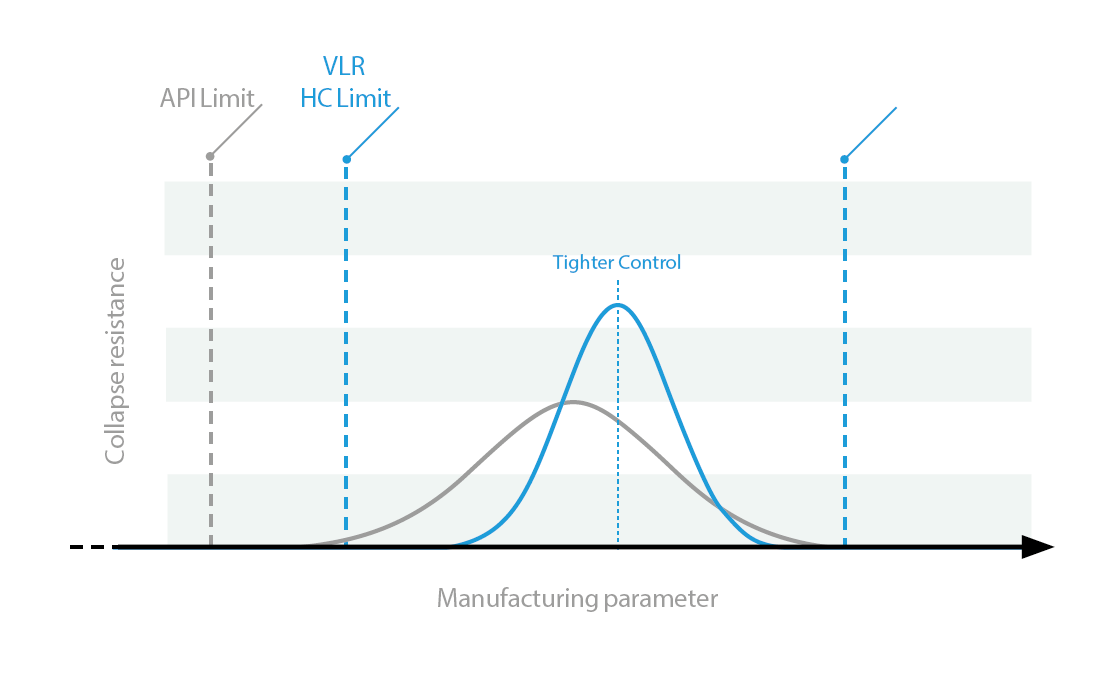

Manufacturing rules

Vallourec applies stringent design of all parameters that influence collapse performance of pipes. By increasing the control of variables such as mechanical properties and geometry during production, the collapse rating is boosted: the more such control becomes tighter, the higher the outcome collapse rating is.

The table below summarizes the difference between API products and Vallourec High Collapse pipes:

| API 5CT | Proprietary High Collapse | |

| Yield Strength | Specified by grade | Restricted range within API 5CT limits |

| Ovality | Not specified | Controlled |

| Eccentricity | Not specified | Controlled |

| Wall Thickness | Defined by weight | Restricted range within API 5CT limits |

| Min Wall Tolerance | 12.50% | Restricted range within API 5CT limits |

| Residual Stress | Not specified | Controlled |

| Manufacturing process | Not specified | Controlled |

| Collapse Calculation | API formula, not guaranteed | Proprietary model |

Additionally, regular collapse and residual stress testing are performed internally to check product performances and to support continuous improvement of our Collapse Proprietary model.

Production inspection

Vallourec controls the of collapse performance of each pipe produced: if a pipe has not met the required collapse performance, it is segregated from the bulk production lot. This is possible thanks to advanced data collection and processing techniques, including individual pipe dimensional characterization, advanced pipe traceability and big-data computational capability.

By applying individual pipe analysis to our pipes, Vallourec overcomes the weaknesses of API 5C3/ISO 10400 Annexes G/H. Consequently, an extra safety barrier to its customers is added.

High Collapse Testing

Collapse testing

Currently, Vallourec is supported by 15+ internal and external collapse chambers, strategically located in the Americas, Europe, and Asia. Our facilities cover a wide range of outside diameter, from 2 3/8” to 24”, and up to 30,000psi.

On top of collapse requested by customers for quality control, Vallourec systematically perform internal collapse for continuous assessment and evolution of its proprietary collapse model. All tests are fully compliant to API 5C3/ISO 10 400 Annex I procedures, which can be summarized as:

- A collapse sample is at least 7 times longer than the pipe specified OD (8 times, if OD ≤ 9 5/8”)

- One residual stress and one tensile coupons are taken adjacently to the collapse sample

- The collapse sample has its OD, wall thickness, ovality and eccentricity detailed measured using non-destructive techniques

- The test apparatus applies increasing hydrostatic pressure on the pipe until it collapses. The maximum pressure is recorded.

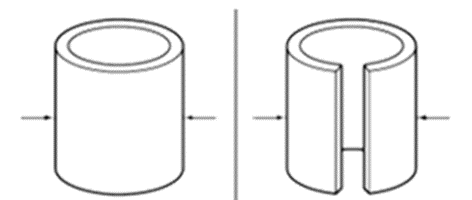

Residual Stress testing

Residual stress tests are systematically performed as part of the quality assessment procedures of Vallourec. The tests are carried out using the destructive split ring method, in compliance to API 5C3 Annex I / ASTM E1928.

In this method, a ring of pipe is slit in the longitudinal direction. Due to the existing residual stresses, the ring can spring open or spring shut, as presented in the schematic figure below. With the information of wall thickness and change in diameter, it is possible to quantify the residual stress levels in the pipe.

Advanced testing

Vallourec is also able to support customer on more specific material collapse characterization, by means of advanced collapse tests that go beyond the usual hydrostatic condition.

Given the fact that operators are often confronted with high temperature levels, it has become a major concern to evaluate the materials behavior under real service conditions. For such advanced analysis, Vallourec and its partners are able to offer elevated temperature collapse tests up to 650°F / 343°C.

Additionally, Vallourec has also supported operators to better understand the impact of imperfect cementing jobs on pipe collapse resistance. Several in-house tests have been conducted by changing the profile and contact surface of the cement, compared to the naked pipe. In the figures below, it is presented one example of a pipe with incomplete cemented job before and after testing.