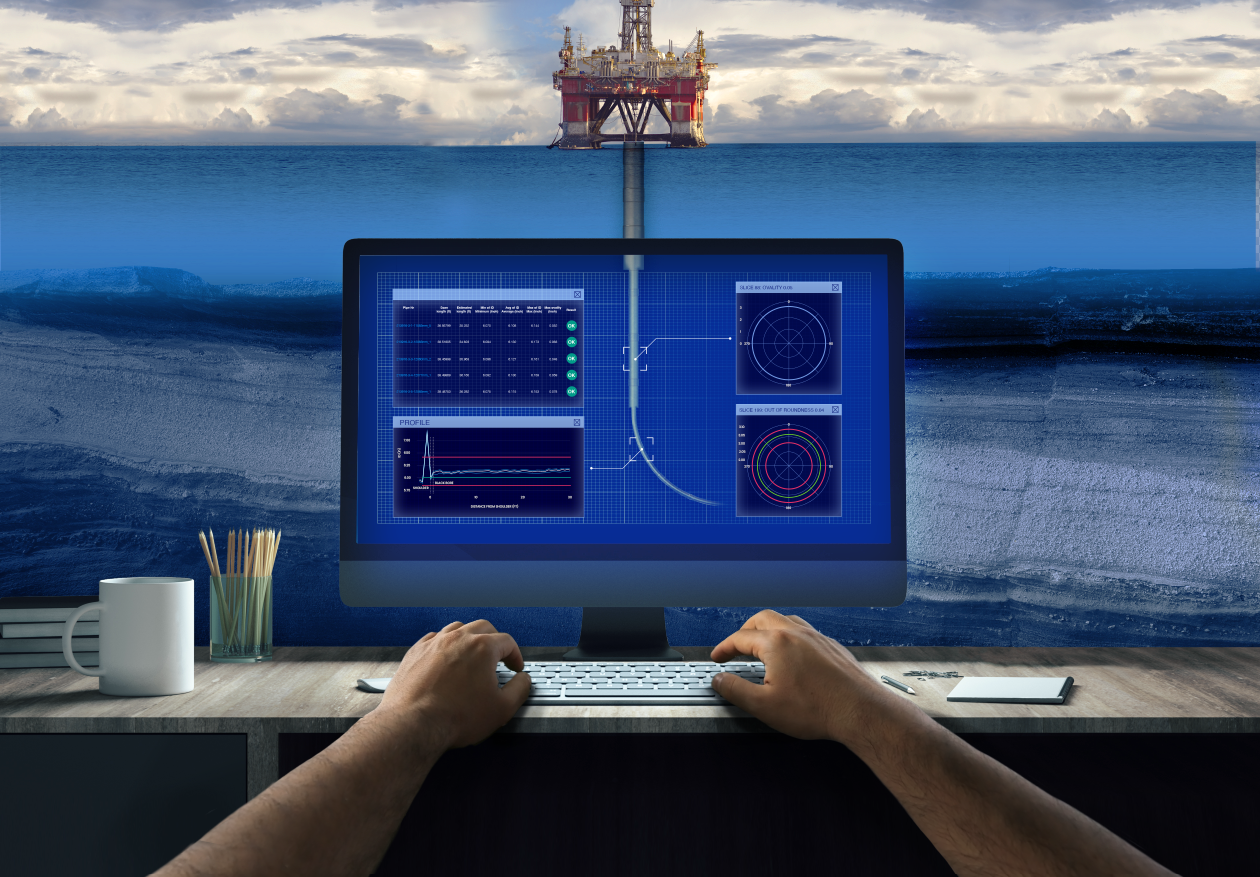

TallyVision

TallyVision improves your pipe running operations thanks to the traceability of each pipe.

Our Solution

Discover TallyVision

This digital solution ensures that pipes and accessories are run according to the planned sequence and proposes the best updated sequence in case of need. It reduces non-productive rig time, eliminates human error, and offers rig crew valuable operational KPIs such as time versus depth.

Traceability & data

- Unique pipe ID orValid: Unique identification number for each pipe

- Barcoding: Marking all pipes, accessories and assemblies: VLR and Non VLR

- Data collection: Barcoding can be executed in Vallourec mills or on external sites (yard, workshop, etc.)

Rig receipt management

With TallyVision, you can access and update pipe data on the deck:

- Pipe scanning: Scan and access each pipe information and history

- Access and update individual pipe data

- Inspection & reject management

Pre-tally management

You can import or generate pre-tally list and modify it before and/or during the running operations. You have also the possibility to modify the order of a planned sequence, remove a planned pipe and/or add a contingency pipe in the planned sequence.

Running Supervision

Field app checks if the right pipe is used at the right position. In case of errors, watchdog alerts will be displayed on the tablet. Operator will accept or reject the pipe and comment to justify his decision. Meanwhile, the rig crew can access to drilling KPIs such as bore volume, steel displacement, cumulated length/depth calculation and ratio of targeted length.

Digital report & Analytics

- Web portal access

- Run-in-hole tally

- Rejected pipes

- Returned pipes

- Operations KPIs

Benefits

Track Record

“Already 55,000+ pipes successfully run with TallyVision.”

| Customer | Country/Region | Type of operation | # of pipe |

| Shell | USA | Offshore | 274 |

| Shell | USA | Offshore | 229 |

| Shell | USA | Offshore | 229 |

| Chevron | USA | Onshore | 1,100 |

| Chevron | USA | Onshore | 567 |

| Coso | USA | Onshore | 26 |

| Total | UK | Offshore | 105 |

| Total | UK | Offshore | 105 |

| Total | UK | Offshore | 465 |

| Petrobras | Brazil | Offshore | 291 |

| Petrobras | Brazil | Offshore | 400 |

| Exxon | Germany | Onshore | 150 |

| Total | UK | Offshore | 351 |

| Total | UK | Offshore | 140 |

| Total | UK | Offshore | 309 |

| Total | UK | Offshore | 50 |

Documents & Resources

Discover our Solutions

More information