Cranes & Lifting Equipment

Crane and lifting equipment manufacturers face numerous challenges: meeting ever-increasing requirements in lifting capacity and height, while producing machines that adhere to stringent safety specifications. Vallourec solutions optimize crane designs for maximum performance, safety and cost-effectiveness.

Benefits

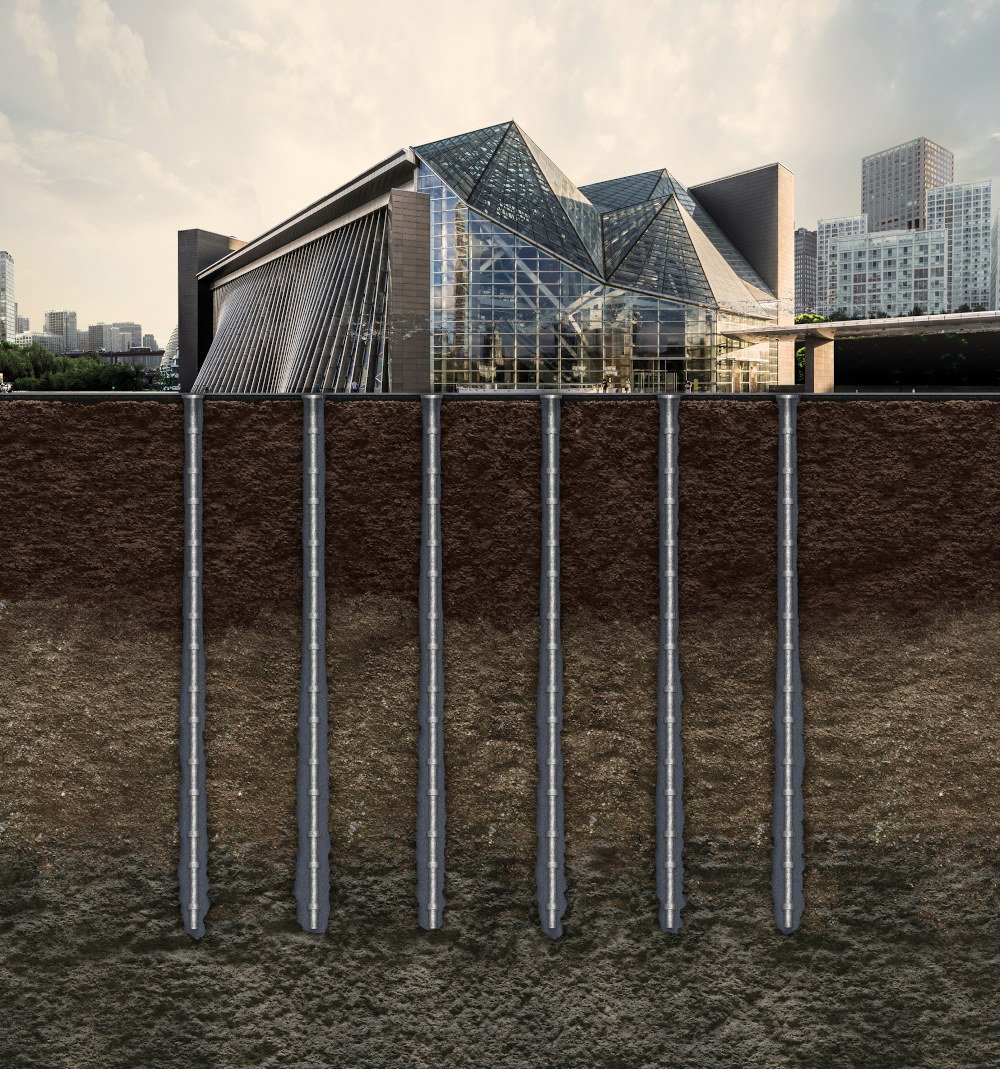

Applications

Crane construction includes a wide range of application specific machinery for load lifting. The scope ranges from small truck mounted cranes with hook loads of 1 t using tubular material for their crane column and as hydraulic cylinders, super tower cranes, featuring hook heights of over 200 m / 650 ft and jib lengths of more than 100 m / 330 ft, all the way to heavy duty crawler cranes with lattice booms and jibs made of high strength steels.

Our products apply to the following types of cranes:

- Mobile cranes

- Crawler cranes

- Ring cranes

- Tower cranes

- Mobile harbour cranes

- Truck loader cranes

- Harbour and dockside cranes

- Lattice tower, boom and jib elements

- Aerial work platforms

Our Products

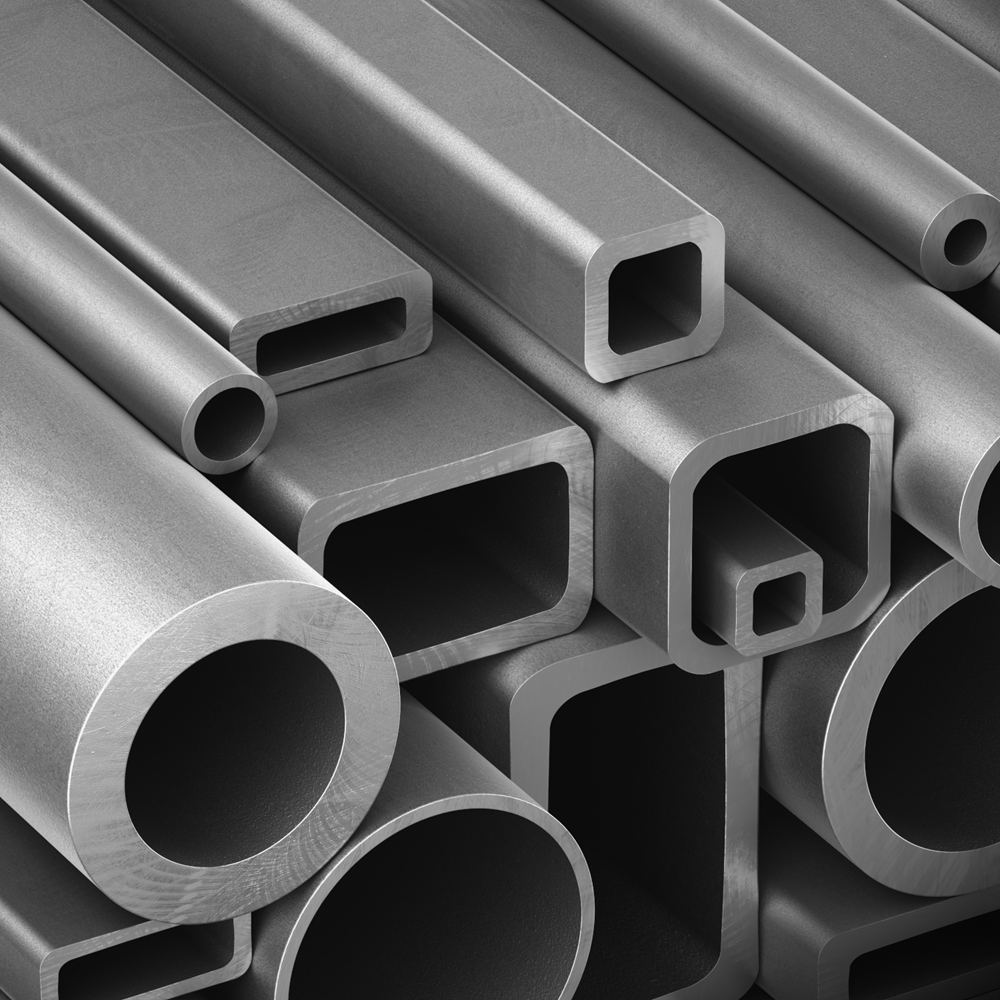

Seamless hot rolled tubes and hollow sections

Seamless hot-rolled tubes and hollow sections offer significant advantages over cold-formed sections, particularly for cranes and lifting equipment. Safer and stronger, since there are no seams, they also feature high buckling resistance under compressive thanks to their uniform microstructure.

These characteristics mean that seamless hot-rolled tubes and hollow sections possess good, uniform properties for structural safety and reliability. They also feature extra-tight corner radii with large, flat connecting areas, a benefit resulting from the hot-forming production process.

Our tubular solutions offer the optimal balance between weight savings and load bearing capacity. Hot finished tubes are part of the highest buckling resistance class, while high-strength steels can support high tension loads.

Product Information

- Structural Hollow Sections in circular, square and rectangular

- Mechanical Tubes

- Main delivery standards EN 10210-1, -2, -3, EN 10297-1, -2, SEW 090-2, ASTM A501

- Forterior® and FineXcell® Grades (355 to 1,000 MPa), Standard grades such as S355J2H, S355NH, S355NLH, S460NH, S460NLH

Grades & Sizes

Vallourec is a full liner in terms of grades and dimensions.

From standard grades such as S355J2H to FineXcell® 960

Particularly well-suited for cranes and lifting equipment, our FineXcell® grade series maximizes performance and reduces weight. These fine-grain structural steels offer yield strengths up to an impressive 1,000 MPa plus excellent processing and fabrication characteristics. They provide an optimal combination of high yield strength and ability to customize.

From small to large dimensions in round and rectangular

Vallourec offers seamless hot-rolled tubes and hollow sections in a wide range of dimensions up to 711 mm and wall thicknesses up to 100 mm. Especially our large dimensions are suited to heavy lifting demands.

Thanks to our unique grade and dimension portfolio, we offer unlimited possibilities for crane designs.

Documents and Resources

Discover our Solutions

More information