Sour Service

Vallourec Sour Service grades meet the most challenging requirements of oil and gas operations in H2S-containing environments. These proprietary grades are suitable for all applications such as unconventional wells and conventional on-shore and off-shore wells, including HP/HT and deep-water fields.

Benefits

Sour service refers to oil and gas exploration and production environments that have enough hydrogen sulfide (H2S) gas to crack metallic materials. Hydrogen sulfide is highly flammable and explosive; it is deadly even at very low concentrations. Sour service is one of the toughest challenges in hydrocarbon production.

When facing a reservoir with significant H2S content, well equipment requires a specific metallurgy to avoid the risk of catastrophic failure which can occur within a few hours. Even when it is not expected to have contact with H2S in normal operations, the casing string must be sour service resistant as it is designed as a second barrier in case of tubing leak. And when the casing is used as tubing like for unconventional wells, the risk is even bigger due to the contact between tubing and fluid production. Today Sour Service environments provide further challenges with deeper wells, higher pressures and extreme corrosive conditions.

Vallourec has more than 30 years in designing Sour Service grades to meet the most challenging requirements of oil and gas operations in H2S-containing environments. These proprietary grades are suitable for all applications such as unconventional wells and conventional on-shore and off-shore wells, including HP/HT and deep-water fields.

Vallourec offers the most cost-effective solution with grades adapted to specific sour service conditions, from mild to unlimited H2S-containing environments, and qualified as per NACE MR0175 requirements.

Product Portfolio

Our wide range of proprietary grades offer improved SSC resistance over standard API grades by carefully designing and controlling parameters specific to Sour Service resistant materials. Their special chemistry and superior quench-and-temper processing ensure wall uniformity and complete martensitic transformation. Superior sulfide stress cracking resistance is obtained by:

- Tightly controlling mechanical properties such as hardness and strength

- Ensuring a homogeneous and fine grain microstructure (finer than ASTM 7)

- The use of practices that promote steel cleanliness minimizing inclusion, segregation and residual stress

- Achieving the formation of fine nanometric and submicronic alloyed precipitates thanks to chemistry and heat treatment fine tuning

| SOUR SERVICES GRADES |

ENHANCED SOUR SERVICE GRADES |

|

| Application | Critical Services | Ultra-critical Services |

| Low Strength Sour Service |

VM 80 S | |

| VM 80 SS | VM 80 IRP | |

| VM 90 S | VM 90 IRP | |

| VM 90 SS | VM 95 SS-D | |

| VM 95 S | VM 95 IRP | |

| VM 95 SS | VM 95 RSS | |

| VM 100 SS | VM 100 SS-D | |

| High Strength Sour Service |

VM 110 MS | |

| VM 110 MS-D | VM 110 RSS | |

| VM 110 SS | ||

| VM 110 SS-D | VM 130 MS | |

| VM 125 SS | VM 130 MS-D | |

| VM 125 SS-D |

All Sour Service grades are offered combined with the High Collapse grades.

Our Sour Service offer is available in the full range of OD from 2 3/8” to 26” with wall thickness up to 2.5”.

Vallourec Sour Service grades have been mainly used in combination with VAM® connections.

Naming

The name of our Sour Service grades generally consists of three parts:

| YY | QC Testing | SSC Domain |

| MS MS-D |

NACE-A NACE-D |

|

| SS SS-D SS-D RSS RSS |

No QC testing NACE method A NACE method D Riser requirements IRP Requirements |

|

When a next generation of Enhanced grade is developed an additional “E” is added to indicates its Extended SSC application domain (eg.: VM 125 ESS).

Low Strength Sour Service grades

Vallourec offers a wide range of low strength sour service materials with H2S unlimited application and improved SSC performance.

The detailed description of each grade is given in a Product Specification. This document is available upon request.

| GRADES | MIN. YIELD STRENGTH (ksi) | MAX. YIELD STRENGTH (ksi) | MIN. TENSILE STRENGTH (ksi) | MAX HARDNESS MEAN (HRC) | NACE QUALITY CONTROL TESTING | SSC QUALIFICATION DOMAIN | |||

| INITIAL pH | ppH2S(bar) | METHOD ATHRESHOLD (% SMYS) | METHOD DMIN K1SSC MEAN (ksi √in) | ||||||

| API L80-1 | 80 | 95 | 95 | 23 | - | - | w/o | w/o | SSC Region 3 |

| VM 80 S | 80 | 95 | 95 | 22 | - | - | w/o | w/o | SSC Region 3 |

| VM 80 SS | 80 | 95 | 95 | 22 | 2.7 | 1 | 90 | w/o | SSC Region 3 |

| VM 80 IRP | 80 | 95 | 95 | 22 | 2.7 | 1 | 90 | 30 | SSC Region 3 |

| API C90 | 90 | 105 | 100 | 25.4 | 2.7 | 1 | 80 | 30 | SSC Region 3 |

| VM 90 S | 90 | 105 | 100 | 24 | - | - | w/o | - | SSC Region 3 |

| VM 90 SS | 90 | 105 | 100 | 24 | 2.7 | 1 | 90 | - | SSC Region 3 |

| VM 90 IRP | 90 | 105 | 100 | 25 | 2.7 | 1 | 90 | 30 | SSC Region 3 |

| API T95 | 95 | 110 | 105 | 25.4 | 2.7 | 1 | 80 | 30 | SSC Region 3 |

| VM 95 S | 95 | 110 | 105 | 25 | - | - | w/o | - | SSC Region 3 |

| VM 95 SS | 95 | 110 | 105 | 25 | 2.7 | 1 | 90 | - | Unlimited H2S |

| VM 95 SS-D | 95 | 110 | 105 | 25.4 | 2.7 | 1 | w/o | 30 | Unlimited H2S |

| VM 95 IRP | 95 | 110 | 105 | 25 | 2.7 | 1 | 90 | 30 | Unlimited H2S |

| VM 95 RSS | 95 | 110 | 105 | 25.4 | 2.7 | 1 | w/o | 30 | Unlimited H2S |

| VM 100 SS | 100 | 110 | 105 | 25.4 | 2.7 | 1 | 85 | - | SSC Region 3 |

| VM 100 SS-D | 100 | 110 | 105 | 25.4 | 2.7 | 1 | 85 | 30 | SSC Region 3 |

SS grades for critical services are widely field proven: our deliveries exceed several 100kT of 95ksi proprietary grades around the world at GoM, North Sea, Middle East, Pre-salt Project in Brazil, Africa, Canada for various extreme applications such as HPHT and Arctic condition.

SS-D and IRP grades are enhanced grades suitable for ultra-critical services. SS-D series, eg. VM 95 SS-D, are proprietary grades with NACE method D as QC testing. IRP series, eg. VM 95 IRP, are proprietary grades compliant with IRP standard, proven by both NACE method A and method D testing. Both tests methods are applied as QC testing.

S series, eg. VM 95 S, are proprietary grades with the same production route and the same mechanical properties of their equivalent SS proprietary grades, for which SSC performances have been proven by mill quality records for more than 30 years. Therefore, no SSC QC testing is performed, the SSC resistance is proven by mill quality record. The advantages of S-series are the reduction of lead-time and cost, while keeping standard API SSC performance

The Vallourec proprietary grades present the following benefits:

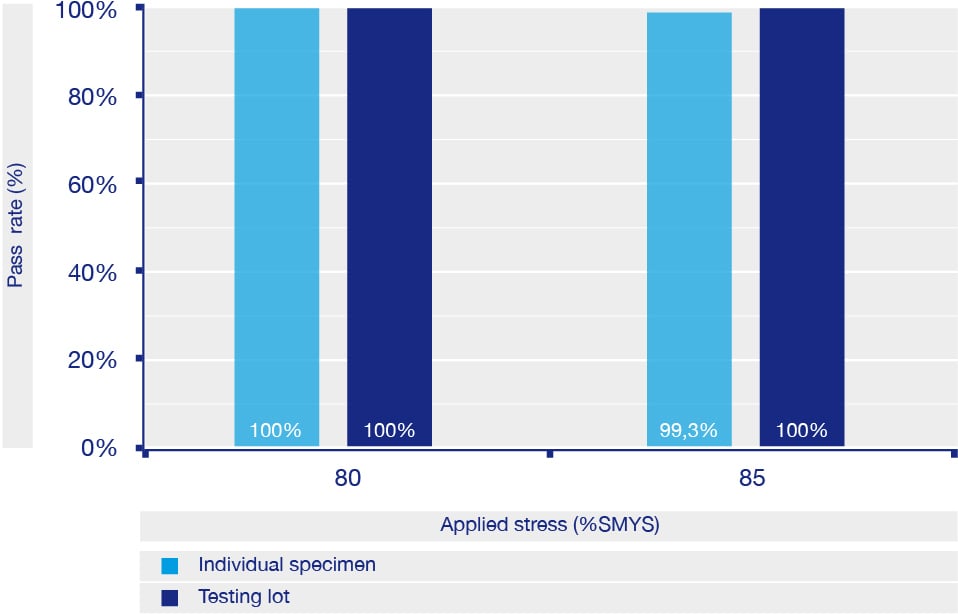

- Qualification of Vallourec proprietary grades as per NACE MR0175 is performed in accordance with NACE TM 0177 Method A at 1bar, 2.7pH and at a higher applied stress than for API grades: 90%AYS instead of 80%AYS which provides a higher safety margin in terms of well design when used under the same conditions as API grades.

- Qualification of method D has been done proven higher KISSC minimum threshold than API 5CT requirements.

- Wide experience on Fit for Purpose testing leading to large database regarding 95 ksi series:

– Specific test solution adapted to special well application

– SSC resistance proven at higher ppH2S up to 15 bar (218 psi)

– SSC resistance proven at lower temperature down to 4°C (39°F) - Strong data base of DCB test performed on casing pipes up to 14’’ in NACE TM0177 solution A condition proven better performances than API minimum requirements.

- NACE method A test is offered using applied stress of 90% SMYS for 95ksi series and 85% SMYS for 100ksi series (instead of 80% SMYS required by API T95 PSL2).

High Strength Sour Service grades

Vallourec offers a wide range of High Strength Sour Service grades specially designed for mild sour environment (SSC regions 1 and 2) and for severe and extreme sour environment (SSC regions 3 and 4). They are widely field proven.

The detailed description of each grade is given in a Product Specification. This document is available upon request.

Grades for Mild Sour Environment

| GRADES | MIN. YIELD STRENGTH (ksi) | MAX. YIELD STRENGTH (ksi) | MIN. TENSILE STRENGTH (ksi) | MAX HARDNESS MEAN (HRC) | NACE QUALITY CONTROL TESTING | SSC QUALIFICATION DOMAIN | |||

| INITIAL pH | ppH2S (bar) | METHOD ATHRESHOLD (% SMYS) | METHOD DMIN K1SSC MEAN (ksi √in) | ||||||

| API C110 | 110 | 120 | 115 | 29 | 2.7 | 1 | 85 | 24 | SSC Region 2 |

| VM 110 MS | 110 | 120 | 115 | 30 | 4 | 0.07 | 90 | w/o | SSC Region 2 |

| VM 110 MS-D | 110 | 120 | 115 | 30 | 4 | 0.07 | - | 27 | SSC Region 2 |

| VM 125 SS | 125 | 135 | 130 | 34 | 3.5 | 0.03 | 85 | w/o | 0.03 bar H2S / pH 3.5 |

| VM 125 SS-D | 125 | 135 | 130 | 34 | 4 | 0.07 | - | 24 | 0.03 bar H2S / pH 3.5 |

| VM 130 MS VM130 MS-D |

130 | 140 | 135 | 35 | 4.5 | 0.014 | 85 | w/o | 0.014 bar H2S / pH 4.5 |

Much confusion exists with regards to C110 application domain : despite that the NACE Quality Control test is carried out at 1 bar of H2S partial pressure as per API 5CT, the validated application domain according to NACE MR 0175 is strictly restricted to region 2

VM110 MS and VM 110 MS-D have been developed as good enough solution for mild sour environment (SSC region 2).

The quality control for production release of these grades is performed in conditions slightly beyond region2, which makes these grades as cost-effective solutions for mild sour environment compared with C110.

VM 125 SS grade has been developed for mild sour environments and slight severe sour environments beyond the SSC region 2. It has been qualified at 0.03 bar H2S partial pressure, 3.5pH and at 90%AYS.

These special conditions are met in HPHT or Deep-water wells. Our deliveries exceed several 10kT of 125ksi sour service products mainly in GoM, for Pre-Salt project in Brazil and in the North Sea, to name just a few examples.

VM 130 MS grade has been developed for HP/HT and deep-water wells in the Gulf of Mexico requesting very high strength carbon steels with corrosion performance in mild sour environment.

VM 130 MS has been qualified at 0.014 bar (0.20 psi) H2S partial pressure, 4.5pH and at 90%AYS.

Grades for Severe Sour Environment

| GRADES | MIN. YIELD STRENGTH (ksi) | MAX. YIELD STRENGTH (ksi) | MIN. TENSILE STRENGTH (ksi) | MAX HARDNESS MEAN (HRC) | NACE QUALITY CONTROL TESTING | SSC QUALIFICATION DOMAIN | |||

| INITIAL pH | ppH2S (bar) | METHOD ATHRESHOLD (% SMYS) | METHOD DMIN K1SSCMEAN(ksi √in) | ||||||

| VM 110 SS | 110 | 120 | 115 | 29 | 2.7 | 1 | 85 | w/o | SSC Region 3 |

| VM 110 SS-D | 110 | 120 | 115 | 29 | 2.7 | 1 | - | 24 | SSC Region 3 |

| VM 125 SS | 125 | 135 | 130 | 34 | 3.5 | 0.03 | 85 | w/o | 0.03 bar H2S / pH 3.5 |

For severe sour environment, our deliveries exceed several 100kT of 110ksi proprietary grades around the world at GoM, North Sea, Middle East, Pre-salt project in Brazil, Africa, Canada for various extreme applications such as HPHT and Arctic condition.

VM 110 SS grade was the first high strength sour service grade developed in the 1990’s. It is manufactured as per API 5CT standard and is fully compliant to C110.

Sour Service performances at elevated temperatures:

The top of the well is usually associated with the decrease of temperature and thus increase of hydrogen embrittlement. Therefore, the risk for sulfide stress cracking (SSC) is higher at the top than at the bottom of the well.

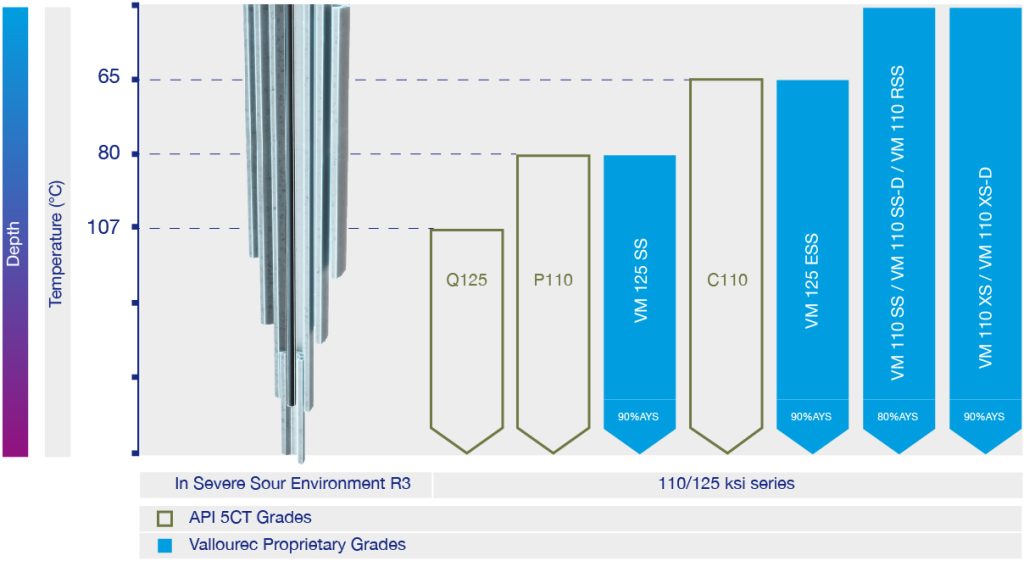

- API C110, P110 and Q125 grades are acceptable for service temperature respectively above 65°C, 80°C and 107°C with respect to SSC as per NACE MR0175 standard.

- VM 125 SS grade has been qualified at 80°C/176°F and VM 125ESS grade at 65°C/150°F as per NACE MR0175 at pH3.5 and 1 bar H2S partial pressure at 90%AYS. This makes them suitable under this severe sour condition above specific temperature as illustrated in the schema.

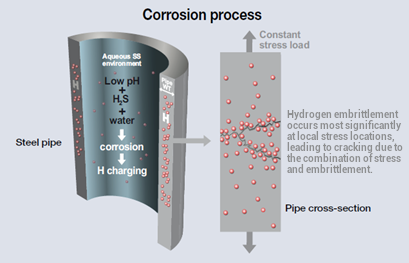

What is Sulphide Stress Cracking (SSC)?

Sour Service refers to well environments containing Hydrogen Sulfides (H2S), which is naturally associated with acidic conditions. Even if not sour at the onset, some wells become sour over time.

H2S in combination with water will release free hydrogen and decrease the pH.

Due to its small sizes, the hydrogen particles are absorbed by the material and interact with the steel which becomes brittle. Hydrogen embrittlement occurs most significantly at local stress locations, leading to crack initiation due to the combination of stress and embrittlement. Then the crack can propagate in a sudden way until catastrophic failure. This corrosive phenomenon is Sulphide Stress Cracking (SSC). In sour environments, the presence of H2S can trigger SSC at stresses below the Yield Strength limit (YS) of the material until its rupture. It is important to notice that even at low levels of H2S, the material is susceptible to SSC phenomenon.

The SSC will appear under the unfavorable combination of the following activating factors:

• Low pH

• High concentration of CO2 and H2S

• High concentration of chloride content

• External stress

• Microstructure

Sour Service Standards and Guidelines for OCTG

| Scope | Highlights | ||

| API 5CT | Casing and Tubing | This standard defines the product technical requirements and specifications of casing and tubing pipes used for oil wells in petroleum and natural gas industries.Besides casing and tubing, it also includes pup joints, coupling stock, coupling material, and accessory materials. | L80, C90, T95, C110 and Q125 are the basis for Vallourec carbon sour service proprietary grades from 80 to 130ksi SMYS. |

| ISO 11960 | Petroleum and natural gas industries - Steel pipes for use as casing or tubing for wells |

Being very similar in content and scope to API 5CT, standard ISO 11 960 also defines the technical delivery conditions and requirements for pipes, coupling stock, coupling material and accessory material for casing and tubing. | L80 13Cr grade is the basis for Vallourec 13Cr proprietary grades. |

| NACE TM0177 | Laboratory Testing of Metals for Resistance to Sulfide Stress Cracking and Stress Corrosion Cracking H2S Environments | It defines how to perform SSC test to evaluate resistance of metals in H2S containing environments, at room temperature and pressure. | It defines 4 testing methods (A, B, C and D) and 4 testing solutions (A, B, C and D) according to the evaluated material (Carbon Steel, MSS and SMSS, or high-strength steels). Solutions A, B and D are the most commonly used for Carbon steels. |

| NACE MR0175/ISO 15156 | Petroleum, petrochemical, and natural gas industries - Materials for use in H2S-containing environments in oil and gas production |

It is the reference standard to select and qualify OCTG materials in H2S-containing environments.Its part 2 focuses on carbon steel and low-alloy steel materials, providing environmental limits for any OCTG equipment, and defining chemical composition per material type. | Its Annex B defines two different testing protocols to simulate the actual service well environments either in full or in mild sour environment |

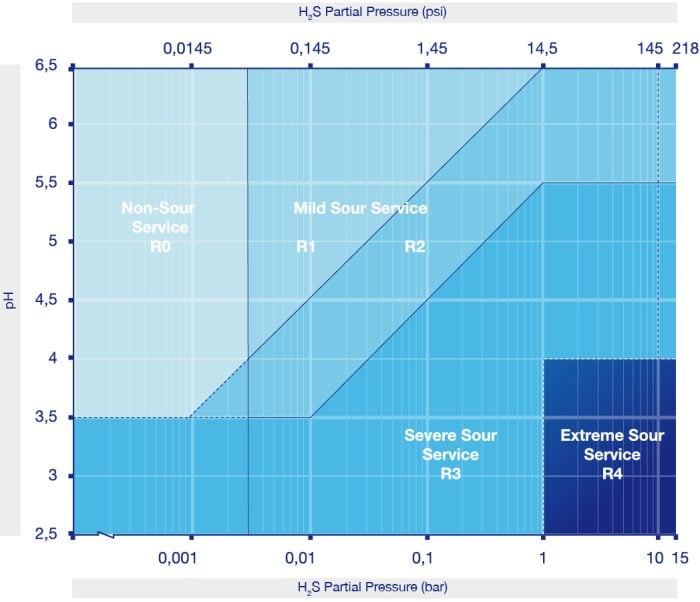

H2S Partial Pressure and pH

Taking into account the combined effects of H2S partial pressure and in situ pH, NACE MR0175 – ISO 15156-2 identifies 4 regions of environmental severity with respect to the SSC of carbon and low-alloy steels.

According to Table 1 from NACE MR 0175 / ISO 15156-2 standard, testing condition for SSC region 3 qualification is defined to 100kPa (1 bar). In reality, however, certain environments can be more severe, combining a low pH level (pH < 4) with a higher H2S pressure.

Vallourec has defined this SSC domain as Extreme Sour Service and named it region 4.

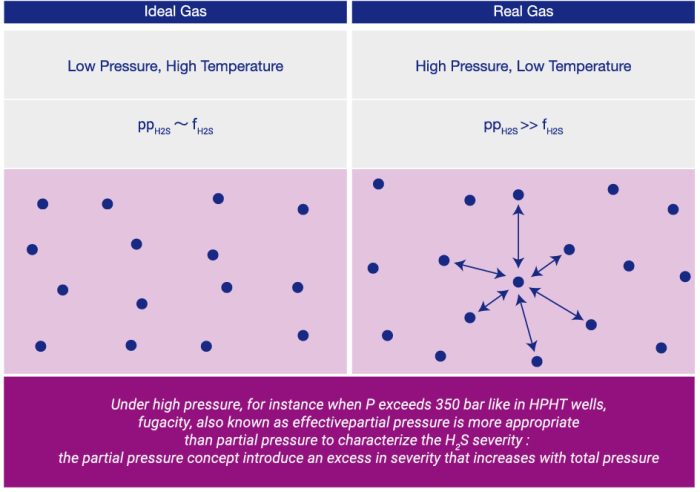

Fugacity

In oil and gas wells, the gas phase does not behave as an ideal gas: it exists interactions (eg. electrostatic) between molecules due to high pressure and high temperature conditions. Consequently, chemical activity of species deviates from ideal conditions and partial pressure of H2S is no more equal to H2S fugacity. Fugacity can be seen as the “effective partial pressure” in a gas phase, this thermodynamic parameter drives gas solubility in water phase. The highest the fugacity is, the highest gas solubility in water is.

NACE MR0175/Technical Circular 1:2017 allows considering the true thermodynamic activity expressed as gas phase fugacity instead of partial pressure of H2S. The partial pressure concept is susceptible to introduce an excess in severity in lab tests when partial pressure of H2S exceeds H2S fugacity. Equipment users may employ H2S fugacity rather than partial pressure to characterize the severity of the production environment. In our Vallourec Research Center in France (VRCF), fugacity calculations are performed thanks to thermodynamic software. For tailored made tests based on fugacity calculations, this “effective partial pressure” of H2S is used for reproducing as best as possible the field’s sour environment exposure.

Temperature

Temperature is another environmental factor which influences the embrittlement phenomenon. Increasing the temperature reduces the risk of hydrogen embrittlement. Decreasing the temperature enhances the risk of sulfide stress cracking (SSC). Therefore, the worst-case scenario for SSC is at the well head under shut-in conditions.

OCTG materials according to API 5CT/ISO 11960 are qualified by NACE MR0175 – ISO 15156-2 for H2S environments as a function of temperature.

Sour Service Testing

Testing standards and methodologies for Sour Service environments are defined in NACE TM0177. It defines and normalizes four test methods (from A to D), methods A and D are the most commonly used. These two tests are complementary as they assess the material resistance against crack initiation as well as crack propagation under H2S containing environments.

NACE Method A test objective is to determine the risk of crack initiation during the first 720h (30 days) of testing. A smooth cylindrical tensile specimen is emerged into H2S containing environment with a constant applied load (commonly 80% or 85% of Specified Minimum Yield Strength SMYS for API grades and 90% of SMYS for Vallourec proprietary grades).

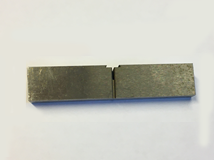

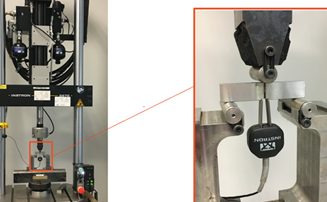

NACE Method D test objective is to determine fracture toughness of the material in H2S containing environment by using Double Cantilever Beam (DCB) specimen. The test provides a critical stress intensity factor value (KISSC); it represents the material’s resistance to crack propagation. This factor is used today for well design based on fracture mechanics theory. Acceptance criterion defines the minimum acceptable value of KISSC for each grade. The standard test duration is 336h (14 days).

Advanced Testing

Our in-depth metallurgical expertise allows to offer fit-for-purpose material qualification testing to reach conditions as close as possible to your well conditions.

High Pressure testing in autoclaves: in addition to our numerous SSC testing equipments for mild to severe sour environment, Vallourec can perform SSC testing (NACE TM 0177 Method A, C and D, NACE TM 0316 for four point bent test) up to 1500kPa (15bar) at room temperature under full H2S environment in autoclave for sour environment.

Simulation of real well environment: Vallourec is able to support you for designing lab test with H2S gas fugacity or H2S partial pressure similar to the well condition.

Hydrogen Permeation test: because hydrogen is a key parameter driving the risk of SSC, we have equipment to determine the impact of the metallurgy, surface treatment and sour environment on hydrogen uptake.

Metallurgical analysis: Our team of experts has the technical skills and tools necessary to assess the microstructural characteristics of steels by combining various in-house methods such as optical microscopy or scanning electron microscopy. We can also rely on advanced technologies (eg XRD Synchrotron and / or high-resolution transmission microscopy) to perform dedicated analyzes for precise identification of precipitates and quantitative assessment. These advanced metallurgical characterization techniques combined with our computational modeling methods (Thermo-Calc, MatCalc) are very helpful for designing our sour service steel grades with improved SSC resistance.

Fracture mechanic: Vallourec provides support in fracture mechanic carrying out J-R and CTOD (crack-tip opening displacement) tests in air or sour environment with SENB specimens (as illustrated). In addition to DCB test, SENT specimens in fit-for purpose sour environment can be used to determine KISSC.

Documents & Resources

New Vallourec VM130MS grade selected for 20K projects in the Gulf of Mexico Beacon has recently qualified our newly developed VM130MS grade for their 20K project of Shenandoah located in the deepwater U.S. Gulf of Mexico, off the coast of Louisiana. First feedback shows a clear interest for this high-strength carbon steel grade combined with sour service performance.