Geothermal Services

With Vallourec® Services, geothermal operators can benefit from dedicated expertise to achieve their targets and tackle their challenges. From well design to running, Vallourec’s team has over 30 years of experience, enabling it to provide support throughout the lifetime of your geothermal projects.

Most geothermal projects have two major objectives. The first is to ensure the long-term integrity of wells. The second is to reduce installation costs and optimize the Levelized Cost of Energy (LCOE). To meet these goals, geothermal operators face numerous challenges – and Vallourec® Services is there to support them.

- Challenging engineering activities

- Require expertise in tubular technology to optimize operational safety and efficiency.

- Logistics management is often complex, with urban or remote sites proving difficult to access during the drilling phase.

- Environmental challenges associated with the corrosive nature of geothermal demand experience to understand and implement best practices.

With Vallourec® Services, geothermal operators can choose from a wide range of expert services to achieve their targets and tackle their challenges. From well design to pipe running, Vallourec’s team has over 30 years of experience, enabling it to provide support throughout the lifetime of your geothermal projects.

Vallourec® Services offers support throughout the value chain:

- Engineering

- Manufacturing, Pipe Management & Repair

- Running Supervision & Traceability.

By combining unique know-how, cutting-edge software and proprietary tools, Vallourec delivers precision expertise across the different aspects of geothermal well engineering.

Well design optimization

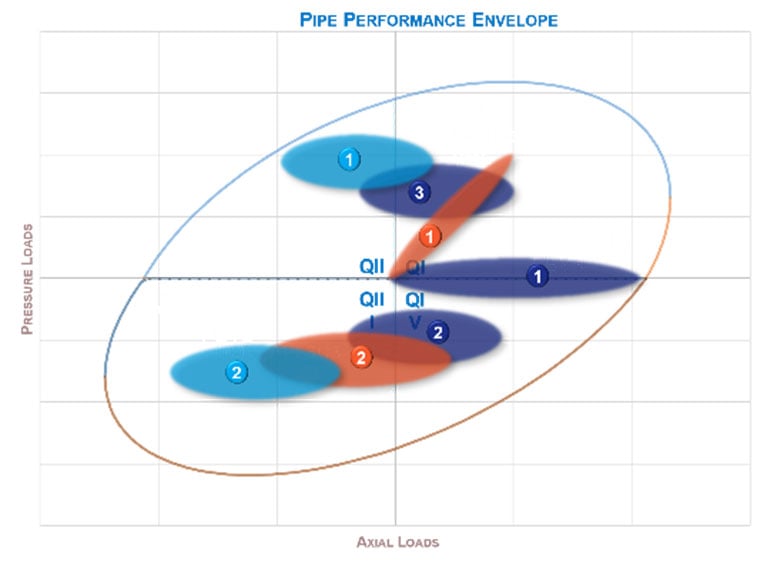

To ensure the structural integrity and resilience of their wells, operators need to carefully select the right combination of tubulars in terms of outer diameter (OD), wall thickness (WT), and material grade.

Vallourec has decades of experience supporting customers with challenging well environments. Its team of expert engineers relies on state-of-the-art software to precisely calculate the best-adapted pipe combinations, while accounting for expected well loads and operator constraints and ambitions.

- Ensure long-term well integrity by preventing corrosion and mechanical failure

- Reduce engineering time by delivering a clear framework for well architecture

- Benefit from a Quality Assurance/Quality Control assessment to ensure long-term safety

Wear, torque & drag studies

By calculating expected wear, torque & drag, along the entire length of the case string, operators can optimize casing dimensions to withstand well loads over time.

Vallourec’s offer is built around a team of experienced drilling engineers using powerful well design software, as well as the DrillScan application. In addition to precise casing wear evaluations, operators benefit from in-depth torque and drag analyses.

- Optimize casing and connection selection to ensure durability and efficiency

- Streamline engineering processes by providing critical data to inform well design

- Benefit from peace of mind by ensuring required quality standards

Material selection

Geothermal wells are subject to high temperatures, high pressure, and corrosive fluids. The material used to build the well must be up to the job.

With decades of experience across different energy sectors, Vallourec has a thorough understanding of which materials work best in which circumstances. Vallourec has an extensive database of material behaviour in geothermal environments, and uses special software to simulate material behaviour in different conditions. Furthermore, Vallourec has its own material testing facility with corrosion evaluation equipment, and can replicate customer well environments in Fit-for-Purpose testing.

- Select the right material for enduring well performance

- Drive cost efficiency in well design

- Adapt & improve existing installations thanks to long-term support

Thermal calculations for closed-loop wells

To ensure maximum efficiency, closed-loop wells must address the challenge of hot and cold fluids co-existing in close proximity.

Vallourec has developed its own simulation tool to provide optimized thermal calculations for close-loop wells. This allows operators to select the best-adapted materials and technologies to minimize heat loss and maximize the temperature difference between the injected and produced fluids. The result is a considerably-improved power output for the well.

- Optimize thermal insulation and heat storage to drive well productivity

- Maximize return on investment for the well design

A European operator worked with Vallourec to conduct a well design optimization review for a new project of multiple geothermal wells. The analysis focused on initial design and expected loads, and particularly on the horizontal stress that can lead to casing collapse. Thanks to the findings, the operator was able to choose the best-adapted premium connection for the production and shut-in phases.

Manufacturing, Repair & Pipe Management

Proximity is key to Vallourec’s offer for tubular repairs and production. With made-to-measure services available close to their sites, operators have the flexibility to deliver rapid responsiveness and long-term productivity.

Tubular Management Services

With decades of experience in tubular storage and management, Vallourec offers a range of services to optimize pipe operations, either directly or through trusted partners.

- Pipe storage solutions ensure tubulars are always protected, kept in the best conditions, and immediately available when operators need them.

- Rig preparation covers a comprehensive range of services, including pipe cleaning, inspection and setup to ensure tubulars are ready for operations.

- Pipe and connection inspections are detailed analyses carried out by Vallourec’s expert team to ensure tubular integrity and full compliance with industry standards.

- A dedicated web portal provides real-time visibility on pipe status, with a centralized platform enabling efficient tracking and management.

- Thread protector circular services allow operators to promote sustainability by recycling used protectors.

How operators benefit

- Save valuable space onsite by storing pipes close to your site

- Save time thanks to pipes delivered in a sequence that aligns with your operations

- Boost rig efficiency by improving pipe preparation and management on the rig

- Increase safety by reducing the need to handle and inspect pipes

- Enable growth by confiding logistics to Vallourec’s experts so you can focus on your core business

- Optimize inventory management thanks to local storage and real-time pipe tracking

Manufacturing & Repair Services

Thanks to a network of around 150 VAM® Licensees worldwide, operators can always find a trusted partner nearby for bespoke solutions in pipe maintenance and manufacturing.

- VAM® connection repairs mean that any issues are addressed rapidly, minimizing downtime to continually maintain the integrity and reliability of your operations.

- Custom-designed accessories can be created with full compatibility with VAM® connections and for the specific architecture and environment of your wells, enhancing your operational performance and efficiency.

- Accessory manufacturing in your area allows quicker response times for the production of essential accessories, which can shorten turnaround times for custom orders and reduce logistical challenges.

How operators benefit

- Reduce lead times & accelerate repairs thanks to maintenance and manufacturing services close to your site

- Boost long-term well performance with made-to-measure pipe design and tailored manufacturing services

- Boost efficiency by minimizing transportation costs and delays thanks to reliable local partners

With limited space around its rig site, a geothermal operator in Germany entrusted Vallourec with the storage, inspection and rig preparation of pipes. Stored less than a 6-hour drive away, the casing pipes can be prepared on demand. Depending on the operators’ needs, certain pipes can be equipped with accessories such as centralizers or cable clamps. When they reach the rig site, all pipes are ready to use, saving the operator valuable time and increasing onsite safety.

With Vallourec’s support, geothermal operators can benefit from peace of mind for the installation and operation of their wells. Our dedicated team provides hands-on guidance and advice to uncover new efficiencies on the rig. We also offer digital solutions to improve running operations and ensure the enduring integrity of wells.

Running supervision

Vallourec’s VAM® Field Service technicians provide onsite support for geothermal operators. Our team of experts can oversee the installation and operation of your wells, ensuring processes conform with safety standards, costs are reduced, and performance is improved.

We also offer pipe and connection inspections to uphold the highest standards of quality, saving you time by detecting any defects early on.

- Extend well lifetime by relying on experts to identify potential issues and address them promptly

- Maximize operational efficiency through meticulous supervision and maintenance support

- Increase safety thanks to onsite guidance from experienced consultants

- Easily obtain rental equipment such as: pressure test fixtures, stabbing guides, handling & well control equipment

transparency with TallyVision

TallyVision is an easy-to-use digital solution providing full pipe traceability on the rig. Through its data-driven approach, it ensures all pipes and accessories are run according to the planned sequence, and brings significant improvements to deck management, running supervision and long-term performance. The solution has been designed using ATEX-certified tablets and cameras, and with its own user-friendly interface.

- Track pipes in real time, anywhere to simplify rig receipt and enhance monitoring

- Optimize running operations by sharing up-to-the-minute KPIs across the rig

- Increase rig safety by reducing the need to handle pipes

- Drive continuous improvement through data-driven analysis of rig performance

An American geothermal operator was pulling casing pipes out of a well, but faced high reject rates due to connection galling during the brake-out. For the second pull-out operation, it sought the support of an experienced VAM® Field Services Technician. This time, the reject rate was reduced to zero.