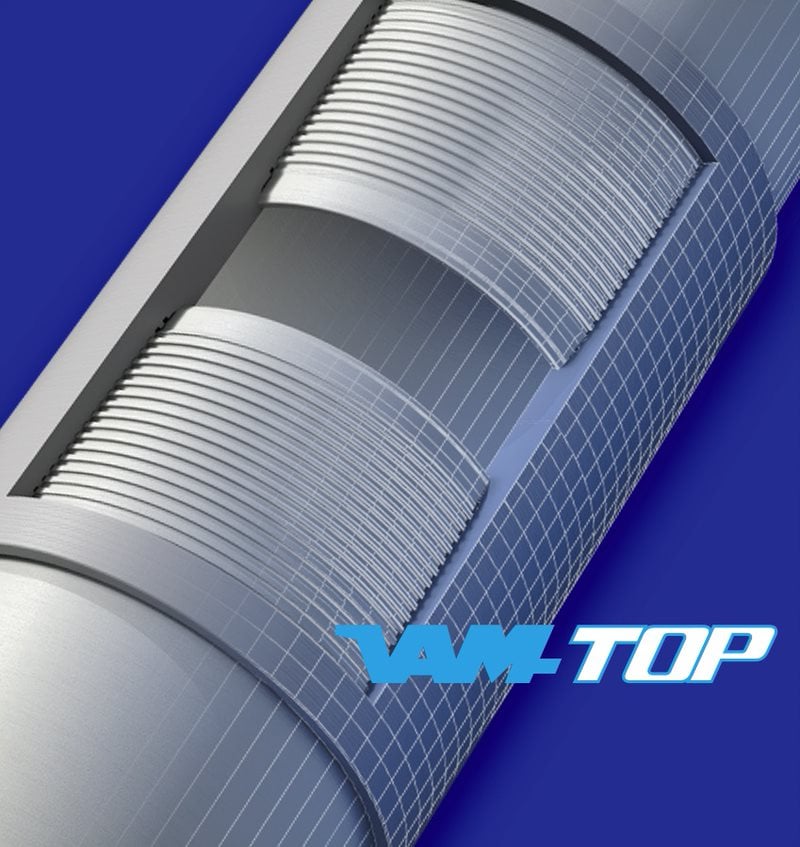

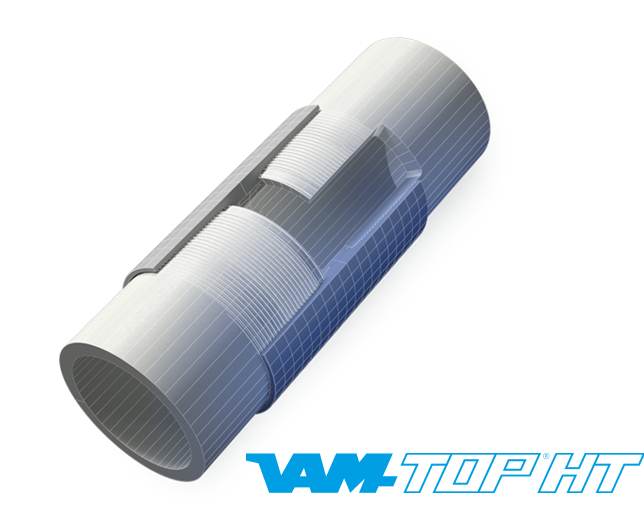

VAM TOP ® HC / VAM TOP ® HT

Premium performances connection for heavy wall pipes and extreme high pressure requirements

Beyond the TOP with Compression or Torque

VAM TOP® HC (High Compression) and VAM TOP® HT (High Torque) are based on the main features of the VAM TOP® connection. While still fully interchangeable with VAM TOP ®, they level up the bar to bring additional benefits: VAM TOP ® HC to address various high-compression applications where it may be necessary to apply extreme compressive loads to the string (elevated temperature inducing compression, compaction, subsidence…). VAM TOP ® HT to provide reinforced torque capability for liners and where high torque is anticipated due to string rotation during running operations (torque rotating liner while running, rotating casing when cementing).