THERMOCASE® VIT – Geothermal

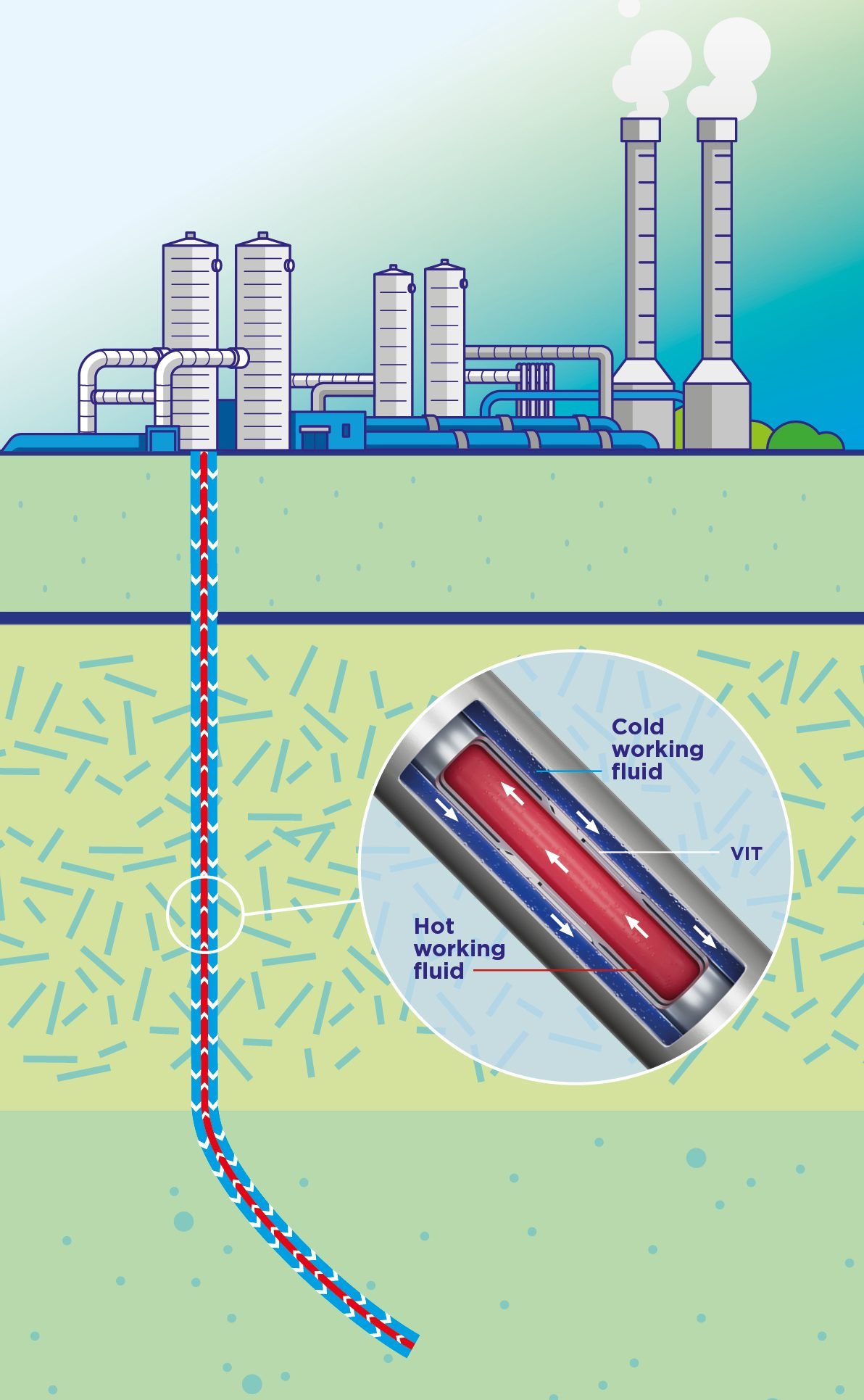

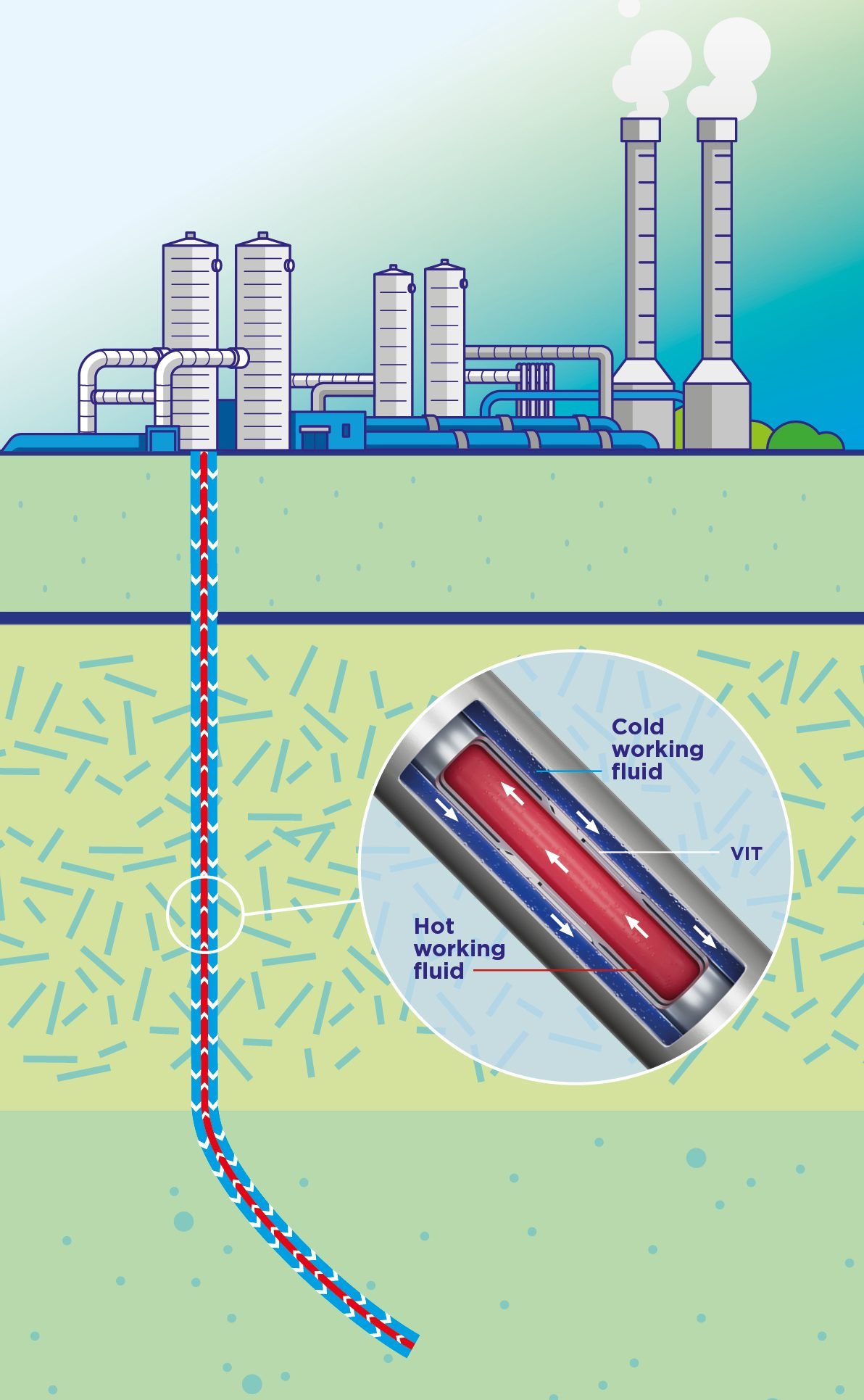

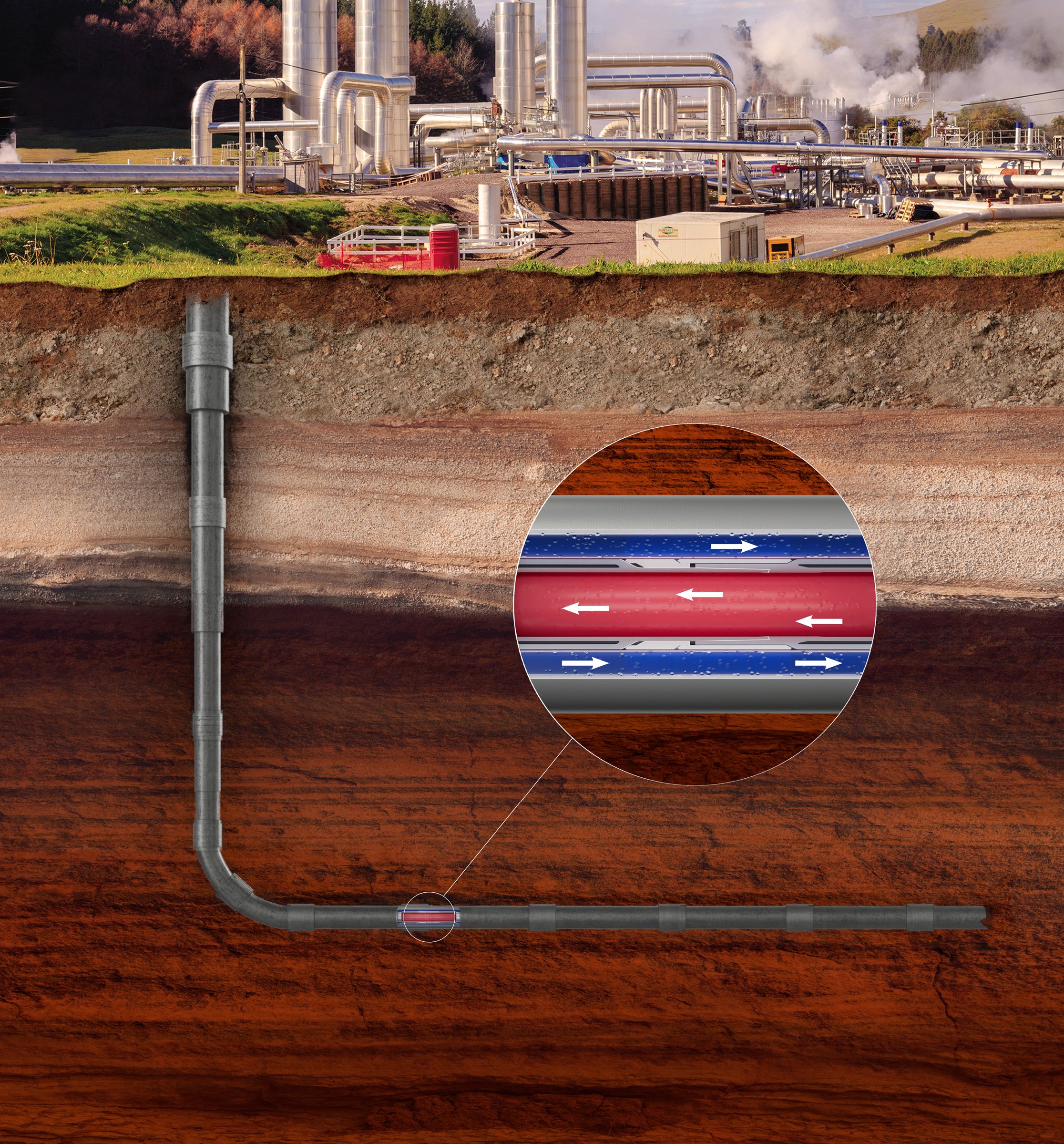

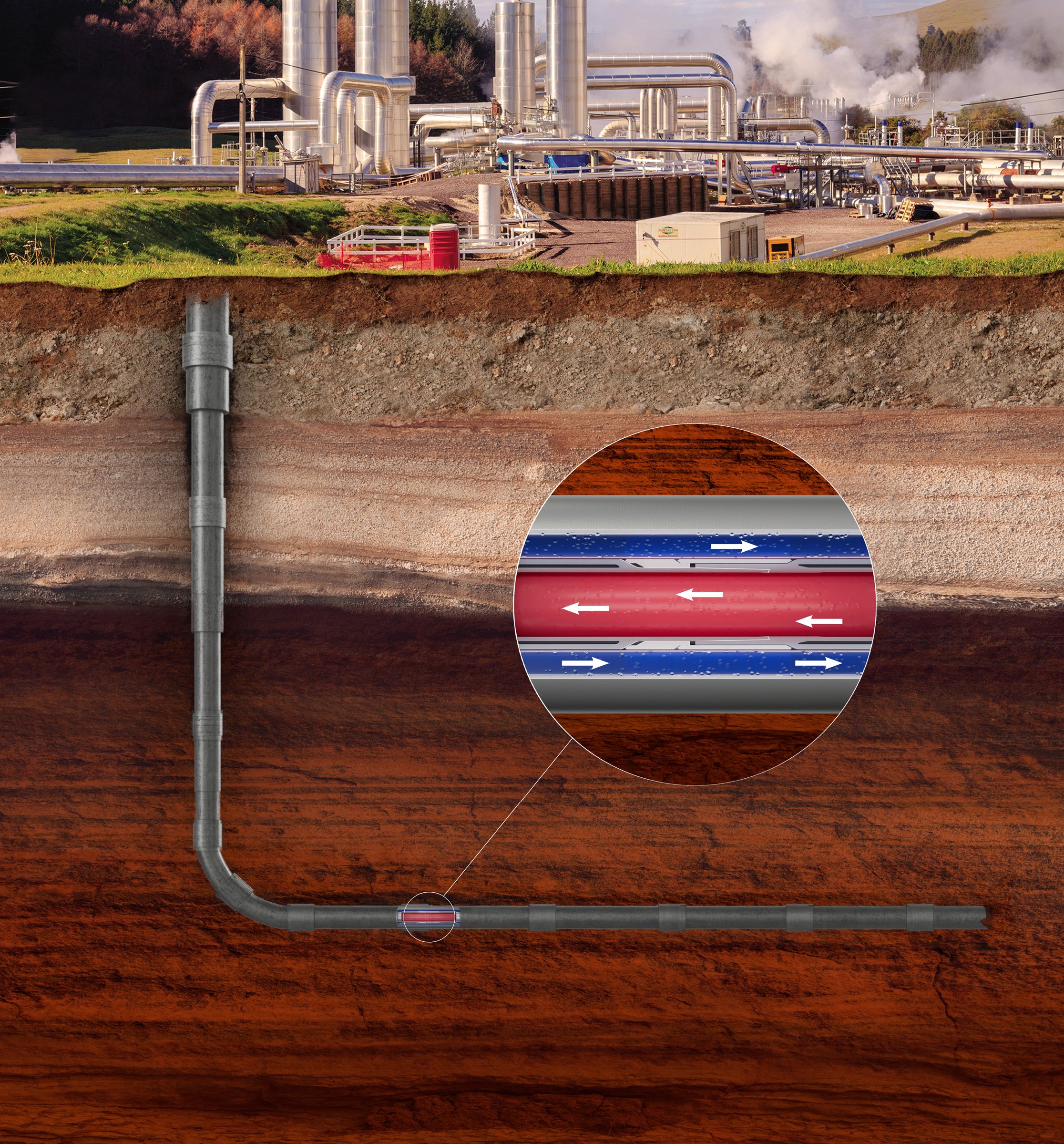

Vallourec’s THERMOCASE® Vacuum Insulated Tubing (VIT) is a cost-effective solution for geothermal closed-loop systems. Thanks to its excellent insulation properties, hot and cold fluids can co-exist in close proximity, which is not possible with standard tubing.

Geothermal closed-loop systems provide the operator with the ability to harness heat from virtually any location on the globe. These systems offer flexibility in selecting the fluid used, which can be water or other options like supercritical CO2 which help optimize the heat extraction and consequently enhance power output. These systems usually need a single well and can be based on a “pipe-in-pipe” solution, with Vallourec THERMOCASE® vacuum-insulated tubing (VIT) as the key component.

- To maximize efficiency, the cool fluid is injected in the annulus between the THERMOCASE® VIT and the casing pipe and gets heated up while flowing down the well.

- Once it has been heated up, the fluid travels up the THERMOCASE® VIT and exits at the surface, where it is used to power turbines or directly for district heating.

- THERMOCASE® VIT’s best-in-class insulation and high-service temperature, make it a central component of the downhole heat exchanger.

THERMOCASE® VIT has been designed to provide high-quality geothermal performance in a number of different situations.

Create a closed loop in hot dry rock

In certain regions, underground rock can heat up to 300°C or more. This superhot rock often has very few fractures, meaning that fluid is not available downhole or its very low permeability does not allow a traditional geothermal regime with a geothermal well. The alternative? THERMOCASE® VIT can be used in a closed-loop system to minimize heat loss between downhole and the surface.

Convert non-productive geothermal wells into closed loops

Around 30% of all geothermal wells drilled are unproductive. This is because of low or inexistant downhole flow rates – and THERMOCASE® VIT can enable large heat extraction even with low mass flow rate from the well. By converting the well to a closed-loop system, efficiency is increased and lost CAPEX is saved.

Convert depleted oil & gas wells into geothermal closed-loop wells

Oil & Gas wells may become depleted and have to be abandoned. In some cases, the bottom-hole temperature is high enough to consider its geothermal potential. With THERMOCASE® VIT, the additional expense of plug and abandonment can be avoided by converting the well into a geothermal well, thus giving it a second life and generating a new revenue stream.

Optimize heat storage

Geothermal operators can store heat underground. This heat is captured during the day or during the summer in underground fluid, and can then be recovered for use at night or in the colder seasons. However, regular OCTG tubulars have low insulation properties, resulting in lost heat during the transfer back and forth between surface and underground. By using THERMOCASE® VIT, such heat loss is prevented, significantly improving efficiency.

THERMOCASE® VIT is a cost-effective solution for geothermal closed-loop systems.

Thanks to its excellent insulation properties, hot and cold fluids can co-exist in close proximity, which is not possible with standard tubing.

Through its unique design, THERMOCASE® VIT minimizes fluid heat loss, increasing the well’s overall power output and making the most of your resources.

Main features

- Provides vacuum between the inner and outer pipes.

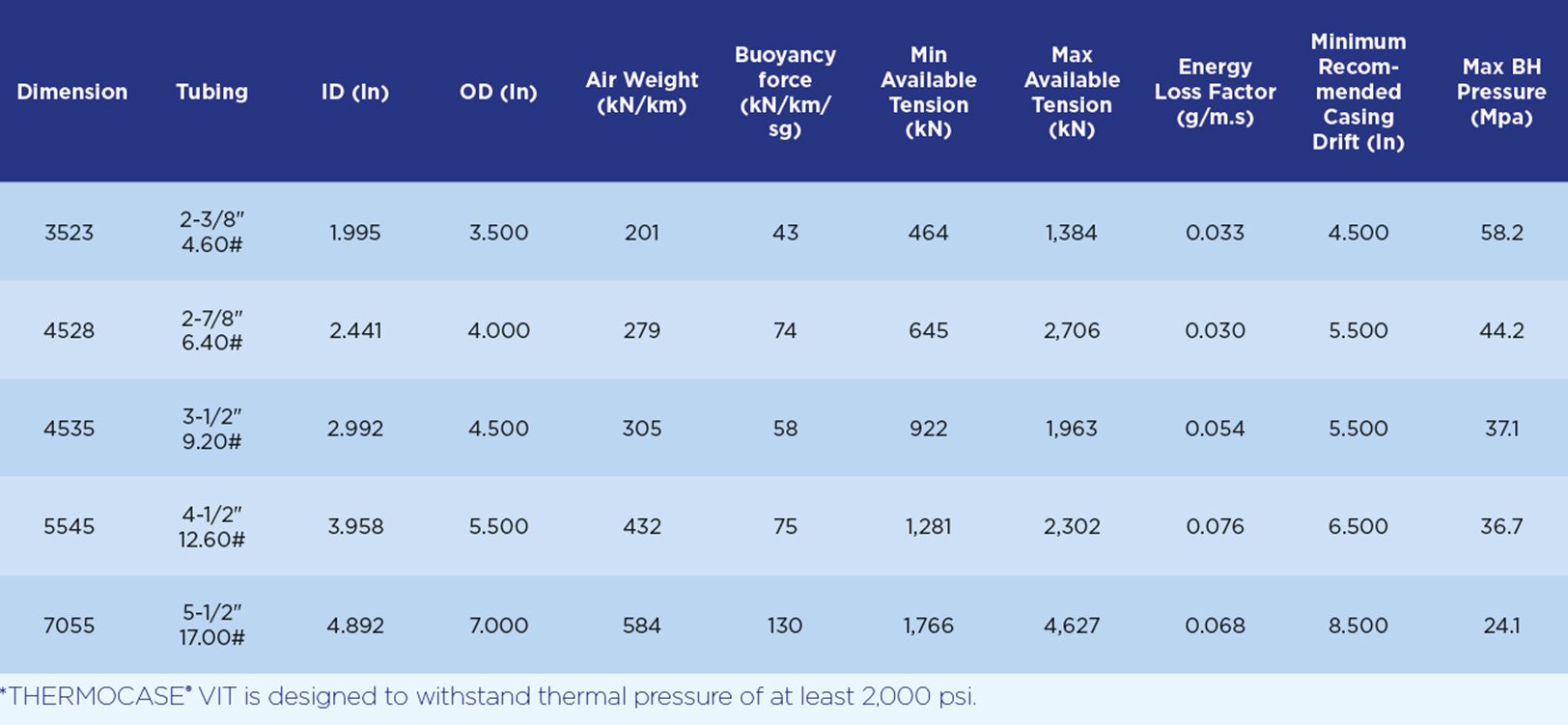

- Heat loss is reduced by up to 95% compared to standard tubing with an energy loss factor between 0.030 to 0.076.

- Designed with API grades.

- Features flush OD and flush ID.

- Proven in the field with major operators since 1999.

Product Range

Options

Choose from these additional features to meet the specific needs of your project:

- Customizable coupling insulation.

- Pre-load.

- Cable clamp for temperature sensors.

- 3Cr, 13Cr and CRA grade materials available.

- Thin wall.

We’re here to help

Our team can support you to get the most from your geothermal well:

- Thermal simulation with dedicated softwares.

- Customized design of THERMOCASE® VIT (tensile performance optimization).

- Well design optimization for a closed-loop system (mix string design).

- THERMOCASE® VIT inspection and K-value recertification.

While closed-loop systems offer advantages including reduced costs and greater heat extraction, they require special tubing. A geothermal operator planned to use an existing unproductive geothermal well in California, USA, for closed-loop testing. The initial casing size was 9-5/8” with an open hole depth of 2,500 meters and a downhole temperature of 160°C. After consulting Vallourec, an optimized design was created using 4.5” x 3.5” THERMOCASE® VIT for a total depth of 1,500m. Vallourec adapted the VIT design to include centralizing fins and clamps, allowing fiber optic cabling to be run downhole for instrumentation.

Thanks to the THERMOCASE® VIT system, generated power is expected to increase from 0.6MW to 4MW electric.

Discover our Solutions

More information