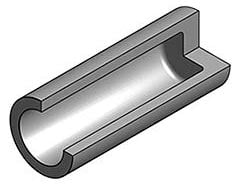

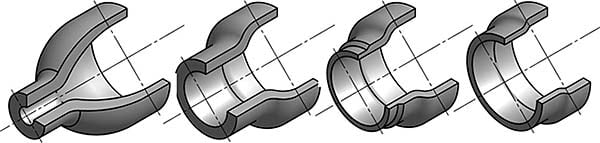

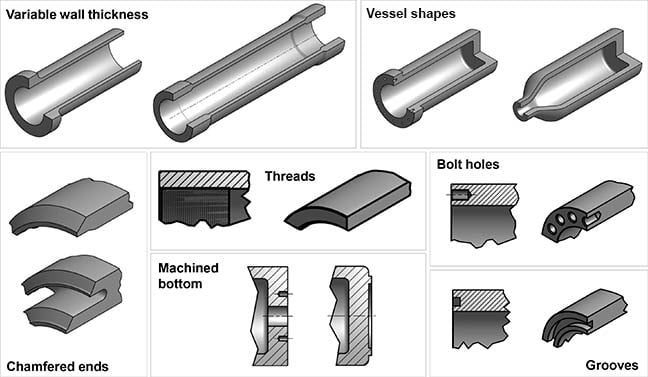

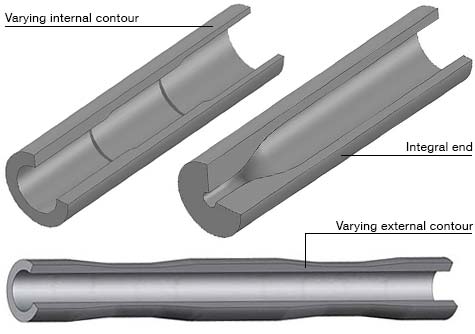

Shaped Tubes

Special products for highly specific applications

The Vallourec plants in Changzhou (China) and in Aulnoye-Aymeries (France) can produce some special products for highly-specific applications such as tubes with integrated bottoms, reduced ends, or expanded ends.