Railway

We offer locomotive and railway wagon manufacturers innovative seamless tubular solutions to reduce the weight of their vehicles. This allows significant reduction of energy consumption and substantial improvement in performance. By reducing wear and tear and overall maintenance our products support cost-effective operations of railway vehicles. One specialty in our portfolio are tubular rail axles.

Benefits

Applications

Our commitment to research and development has resulted in our innovative Tubular Railway Axle. Thanks to this development, the weight of railway vehicles can be significantly reduced.

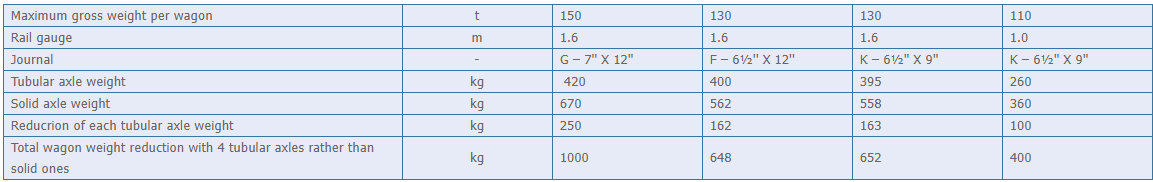

The table below shows different types of railway axles, commonly applied for iron ore wagons, and the reduction of weight that a tubular version can afford.

Even with the reduction of the weight of the tubular axle to 420kg (OFT 39U), which corresponds to the reduction of 250kg on the weight of a solid axle of 670kg, it is still expected the same performance from the 7” X 12” broad gauge solid axle.

As a consequence, the number of trips of iron ore transport trains between a mine and the harbor can be reduced.

Also other kinds of rail vehicles will benefit from tubular axles: lifetime of the whole railcar structure is increased and the load and wear on the track is reduced.

Other applications for our tubular products

- Structural elements in rail vehicles (e.g. bogies, rail car passenger compartments, central beam, frame parts for gondola cars)

- Shock absorbers (e.g. in couplings)

- Cylinder liners for diesel engines

- Hydrogen: technical equipment of trains and stations

Our Products

Seamless tubular products for railway

From our global manufacturing plants with their highly productive rolling and forging mills, multi-purpose heat-treatment facilities and specific finishing lines we provide:

- Seamless tubes and hollow profiles (round/ square/ rectangular/ special shapes)

- Hot-forged and machined seamless hollow axles with integrated spindles

- Machined tubular components

Our product and service portfolio further include on request

- High-quality steel from our internal sources

- Non-destructive testing (US and EMI)

- Cutting to customized short lengths

- Outside shot-blasting

- Outside peeling

- Outside grinding

- Pre-machining of ends

- Various options of bundling and packaging

- Customized logistics

Thanks to our tailor-made portfolio for railway industry you can easily create cost-effective and flexible solutions for your customers.

Grades & Sizes

We offer a unique range of steel grades, from standard grades up to high performance premium grades: in accordance with most international standards (e.g. ISO, EN, DIN, ASTM, SAE, AAR, …) as well as customized grades acc. to your specification, providing solutions for your specific needs. For example our Forterior® and FineXcell® grades enhance your design with extra resistance, even for the highest multi-axial and fatigue stresses. They also support the design of weight-optimized structures without compromising on performance. This means either:

- Less material is needed and equipment can be lighter

or

- Performance is enhanced, but with the same total weight

About Forterior®

- High yield strength with a range between 450 – 620 MPa

- Impact test values guaranteed up to – 20 °C

- Dedicated to performance welding

About FineXcell®

- High yield strength with a range between 690 – 960 MPa

- Impact test values guaranteed up to – 50 °C

- Outstanding weldability

Sizes

Our diversified mills ensure the widest dimensional range in seamless tubular solutions for your flexibility.

- Round Tubes: Discover the dimensional range

- Rectangular hollow Sections: Discover the dimensional range

- Square hollow Sections: Discover the dimensional range

- Special geometries/shaped components: Upon request:

Development of customized solutions – applicable also for small quantities, e. g. prototypes or small lot sizes.

Documents and Resources

Soluções tubulares que trazem inovação ao transporte

Tubular solutions to drive innovation in transportation

Discover our other solutions

More information