Civil Construction

For technically demanding buildings and bridges and cost-effective, easy-to-fabricate structures Vallourec offers a wide range of solutions. Our seamless hot-finished steel tubes in different dimensions as well as PREON® box, a solution for standardized systems, make your construction plans a reality.

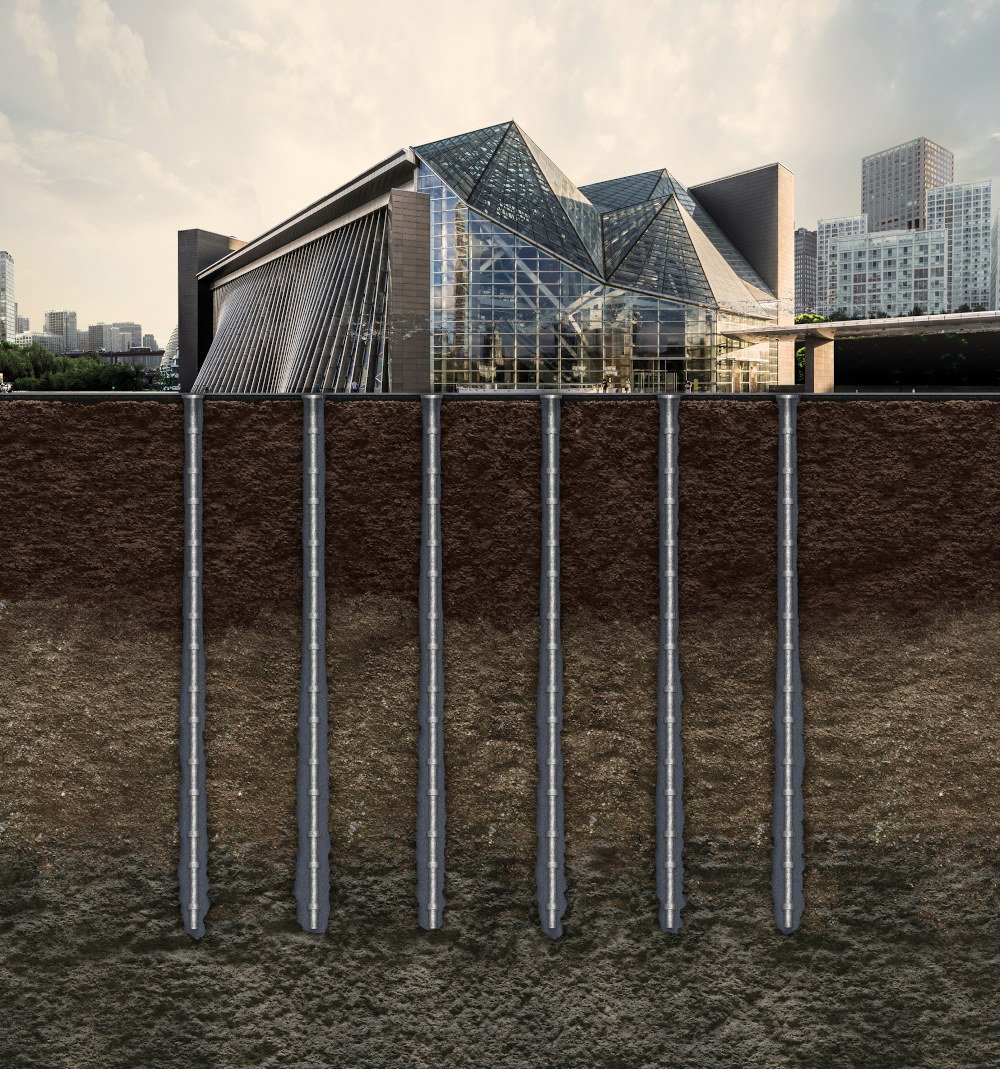

Sustainability for modern structures

Seamless steel tubes are perfectly suited for safe and aesthetic buildings. Thanks to their strength and robustness, they can support wide spans without the need for view-blocking columns.- Airports and terminals

- Sport stadiums

- Event halls

- Stations

- Skyscrapers

- Glass facades

- Pedestrian and bicycle bridges

- Motorway bridges

- Railway bridges

Seamless steel tubes for unique and standard structures

For decades, Vallourec is an active member of CIDECT, supporting the development of design rules for structural hollow sections. As a result, the Eurocode 3, covering design and construction rules for steel structures, are driven by CIDECT.

Due to long lasting expertise and production feasibilities, our offer will meet the challenges of your construction project. Offering a wide range of sizes and shapes – mainly in round, square and rectangular, our tubes support your design and fabrication processes thru:

- Design flexibility – thanks to wide range of steel grades

- Outperforming to requirements of EN 10210

- Weight savings – due to better sectional properties

- Best-in-class buckling resistance

- Sound weldability

- High load bearing capacity

- Easy processing – as there is no distortion

- Time savings – due to tight corner radii (Link)

- Aesthetic and efficient design

- Availability – also in small order quantity

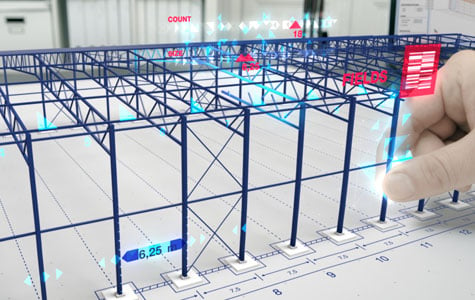

Our PREON® box solution for halls and hangars

Wide, column-free, flexible-space halls require strong facades and roof constructions with large, unsupported spans. For cost-effective industrial buildings, our PREON® box solution is an iterative software that quickly creates static calculations based on steel Structural Hollow Sections. It offers extra flexibility: you can change your design as needed: PREON® box updates the static calculations instantly. From single to multi-bay halls with spans up to 100m or more, PREON® box optimizes your design and offers a high potential for time and cost savings.

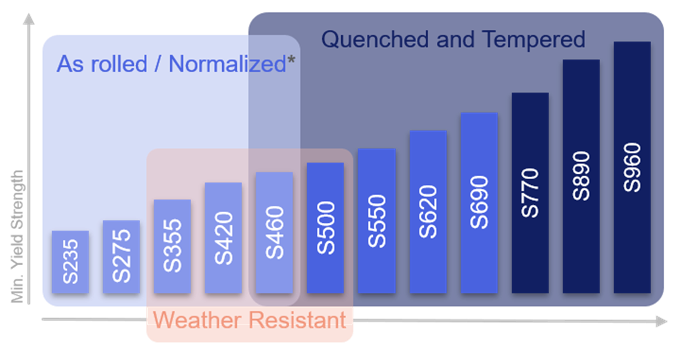

Grade portfolio for structural tubes

Our wide alloy portfolio covers low up to high strength fine-grain as well as specialties like Corten-steels.

* Including normalized rolling

Dimensional ranges for structural tubes

As full liner, our portfolio of dimensional ranges is the widest in the industry. It includes round tubes, square, rectangular and special shapes like hexagonal or elliptic and extra-long sections are available upon request.

Typical dimensions are:

Circular: Outer diameters from 21.3 to 711mm and wall thicknesses up to 100mm

Square: Outer diameters from 40×40 mm to 300×300 mm and wall thicknesses up to 25 mm

Rectangular: Outer diameters from 50×30 mm to 400×200 mm and wall thicknesses up to 25 mm

Special shapes upon request:

Worth to mention that our technical team – having long lasting experience in different applications – is eager to support you in material selection and design.

Structural Hollow Sections & Dedicated software to plan smart & design better